Can Bottom Coding Visual Inspection Technology: Principles, Applications, and Future Trends

With an inspection speed of 72,000 cans per hour and over 99.9% accuracy, how can visual inspection technology safeguard beverage quality and safety?

In today's rapidly developing food and beverage industry, cans, as a mainstream packaging format, are particularly important for product quality control. Can bottom coding, as a carrier of product information, is a crucial means of tracking key information such as production date and batch number. However, defects in the coding process can cause significant losses to companies.

Traditional manual inspection methods are no longer able to meet the demands of modern high-speed production lines, and automated inspection systems based on machine vision are becoming a key technology to address this issue.

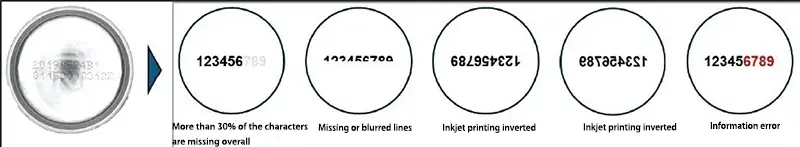

1. Quality Challenges of Can Bottom Coding

In the can beverage production process, coding quality is affected by a variety of factors. Improper adjustment or misalignment of the water blower in front of the printer can result in incomplete removal of water droplets from the can bottom, resulting in blurred or missing codes.

Ink clogs in the printer nozzles can also lead to production accidents such as missed or missing codes. Furthermore, misalignment of the printer's trigger sensor or printhead can cause problems such as missing characters, missing codes, or incorrectly positioned codes.

These coding defects not only affect product traceability but can also lead to consumer complaints and negatively impact a company's brand value. Statistics show that, on average, each production line needs to quarantine approximately 8,000 cases of wine annually due to coding defects, requiring approximately 1,600 hours of manual reprocessing and resulting in nearly 200,000 yuan in labor costs and consumables.

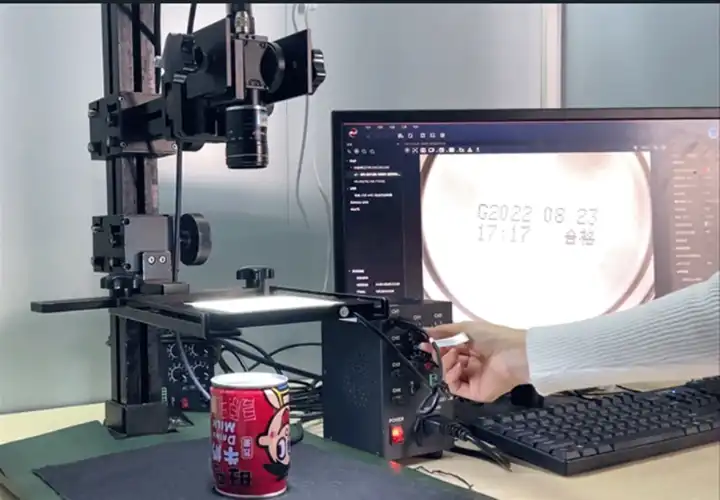

2 .Composition and Principle of a Machine Vision Inspection System

A complete can bottom coding visual inspection system primarily consists of a light source and vision processing system, an electrical control and human-machine interface system, and a defective rejection device.

When a can passes through the imaging system, a metal proximity switch triggers the light source strobe and an industrial smart camera to capture a high-speed image of the can bottom. After the smart camera analyzes and processes the image, the electrical control system executes the inspection results, enabling automatic sorting of defective products.

Light Source System

Due to the concave structure of aluminum can bottoms and the reflective properties of the metal surface, the inspection system typically uses a spherical integrating light source. The hemispherical inner surface of this light source, with its integrating effect, evenly reflects light emitted from the bottom 360 degrees, ensuring uniform illumination across the entire image and significantly improving image acquisition stability.

Image Acquisition System

To capture clear images of high-speed moving cans, the system requires a high-performance industrial smart camera. Smart cameras like the Cognex In-Sight Micro1400, while compact (only 30mm x 30mm x 60mm), can meet the inspection requirements of the highest-speed production lines, achieving inspection speeds exceeding 1,350 pieces per minute.

Processing and Execution System

The system utilizes an industrial computer and PLC (such as the Siemens S7-200) as its core control system, taking into account factors such as speed, stability, and cost-effectiveness. These components are responsible for executing the image processing algorithm and outputting the final sorting signal.

3 .Evolution of Inkjet Printing Character Recognition Algorithms

With technological advancements, algorithms for recognizing the character of inkjet prints on can bottoms have undergone a significant evolution from traditional image processing to deep learning. Traditional OCR Technology

Early systems often used OCR character reading and verification technologies developed using spreadsheet scripting languages. These methods leverage the mature machine vision algorithms embedded in smart cameras to implement functions such as presence detection, surface defect inspection, and dimensional measurement, allowing for rapid deployment without complex user programming.

Application of Convolutional Neural Networks

In recent years, character recognition methods based on convolutional neural networks (CNNs) have demonstrated significant advantages. These methods segment and classify characters in images offline to build a character library, then train them using an improved CNN learning method to form a stable classifier.

In online inspection, images are captured in real time, and characters are segmented and then classified using a classifier. This significantly improves detection accuracy while ensuring real-time performance.

Dot Matrix Character Segmentation Technology

Researchers have developed a specialized character segmentation algorithm tailored to the characteristics of dot matrix inkjet printer characters. This algorithm uses the MSER (Most Stable Extremal Region) method for initial localization of character regions and the connected domain method for finer localization, effectively addressing the challenges of projected segmentation of dot matrix characters.

4. Key Technological Breakthroughs and Innovations in the System

The can bottom coding inspection system has achieved numerous technological breakthroughs, enabling it to meet the demanding requirements of industrial sites.

Character Positioning Technology

To address the problem of cans being easily rotated during the coding process, the modern inspection system uses MSER and morphological area methods to locate the character area, eliminating interference from character scale and rotational transformations. The rotation angle of the character area is calculated using the minimum enclosing rectangle, and tilted character areas are corrected to a horizontal orientation using affine transformation and linear interpolation.

Fusion of Deep Learning and Traditional Algorithms

The system innovatively combines convolutional neural networks with traditional image processing techniques. CNN performs feature extraction and pattern recognition, combined with edge detection and morphological processing techniques, to achieve high-precision code recognition and defect detection. This fusion approach not only improves recognition accuracy but also significantly reduces false positives and missed detections.

Intelligent Learning System

The new generation inspection system is also equipped with an intelligent learning function that continuously optimizes the inspection model based on historical inspection data, automatically identifies new coding patterns and defect types, and updates inspection rules, significantly improving the system's adaptability and scalability.

5. Industrial Application Cases and Benefit Analysis

Actual industrial applications have demonstrated that machine vision inspection systems have achieved significant results in can bottom coding inspection.

Jinan Maotong Inspection Equipment Co., Ltd. has achieved automation and intelligent coding inspection through its independently developed can bottom coding inspection equipment. The system has reduced the coding defect rate by 99%, helping customers save approximately 220,000 yuan per production line annually, reducing manual inspection hours by 1,600 hours per year, and significantly improving production efficiency.

In terms of technical indicators, modern visual inspection systems can achieve recognition accuracy rates exceeding 99.9%, inspection speeds exceeding 1,350 pieces per minute, and equipment stability guaranteed to operate continuously for more than two weeks. Compared to imported equipment, the cost of independently developed equipment is significantly lower, at only 10% of imported equipment and less than 50% of domestically produced equipment.

6 .Future Development Trends

With the continuous development of artificial intelligence and the Internet of Things, visual inspection technology for can bottom coding will become more intelligent and efficient.

The further integration of deep learning algorithms will enhance the system's ability to identify complex defects. At the same time, the application of 5G technology will enable real-time remote transmission and analysis of inspection data, providing more timely quality feedback for production lines.

Furthermore, the collaborative working model of edge computing and cloud computing will balance the system's real-time processing capabilities with the needs of big data analysis. With the popularization of modular design concepts, future systems will be more flexible and able to quickly adapt to the inspection needs of different production lines and product types.

Looking ahead, as automation levels in the food and beverage industry continue to increase, visual inspection technology for can bottom coding will be promoted and applied in more production lines. This will not only effectively improve product quality control but also provide valuable experience for the intelligent upgrade of the entire manufacturing industry.

The development and improvement of this technology will have a positive and far-reaching impact on breaking the monopoly of foreign equipment and enhancing the competitiveness of my country's manufacturing industry.