"AI Quality Inspector" for Plastic Bottles: Making Every Bottle Stand the Test of Microscopes

When you unscrew a bottle of mineral water, have you ever wondered what kind of "hardening" this seemingly ordinary transparent container has undergone before it reaches your hands? In the smart factory of a beverage giant, every plastic bottle undergoes a "full-body scan" by an AI vision system. From tiny scratches of 0.1 mm to liquid level deviations of 0.5 ml, from bubbles at the bottom of the bottle to the angle of the cap's fit, no flaw escapes the AI's scrutiny. This quiet quality revolution is redefining safety standards in the plastic packaging industry.

Core Advantages of AI Vision Inspection

Compared to traditional inspection methods, AI vision inspection offers many advantages. First, it offers fast inspection speed, enabling real-time inspection on high-speed production lines, significantly improving production efficiency. Second, it offers high accuracy, capable of detecting subtle defects that are imperceptible to the human eye. Furthermore, AI vision inspection systems can reduce labor costs and mitigate the subjectivity and errors associated with manual inspection.

Bottle Cap Anomaly Inspection

AI vision inspection has demonstrated its strength in detecting anomalies in bottle caps. Traditional manual inspections can easily miss subtle defects due to fatigue and negligence, but AI vision inspection systems can accurately determine whether bottle caps are tightened properly and whether they are damaged or deformed. Once a cap anomaly is detected, the system immediately issues an alarm and rejects the unqualified product, significantly improving product safety and sealing.

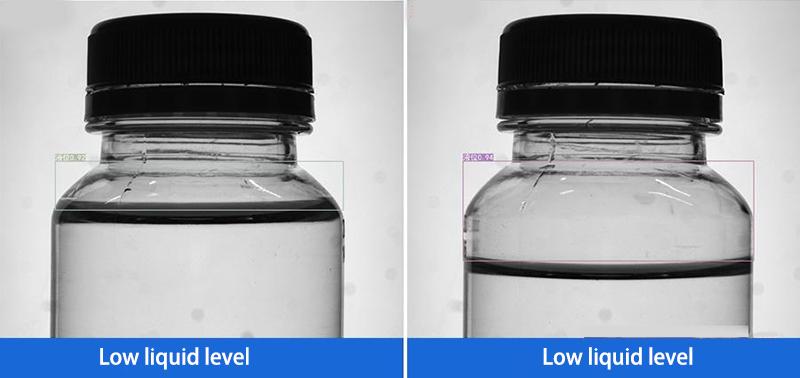

Liquid Level Anomaly Inspection

Liquid level anomaly detection is equally effective. For beverage manufacturers, inconsistent liquid levels not only affect product appearance but can also lead to cost deviations. AI vision inspection systems can accurately measure the liquid level in each bottle, ensuring product compliance and avoiding customer complaints due to liquid level issues.

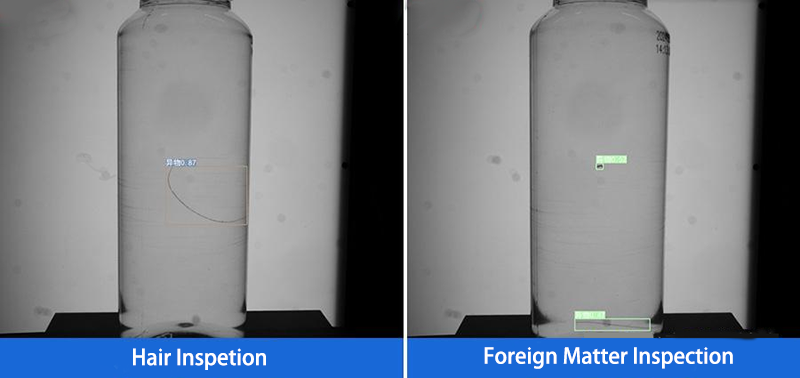

In-Bottle Foreign Object Inspection

In-bottle foreign object detection is a key component of plastic water bottle quality inspection. During the production process, even the smallest foreign object can pose a threat to consumer health. AI vision inspection technology, with its high-resolution imaging and powerful algorithms, can clearly identify impurities within the bottle, safeguarding consumer health.

Full-Dimensional Quality Control

In addition to defect detection, AI vision technology can also accurately measure bottle dimensions to ensure that bottles meet design specifications. It can also detect defects in bottle packaging materials, proactively identifying potential problems and preventing product damage caused by packaging issues.

Visual AI Ecosystem

The Visual AI Ecosystem utilizes a collaborative "software-hardware-cloud platform" architecture to overcome the hardware limitations of traditional local model training, enabling small-sample detection model training in a cloud environment. Its localized inference software achieves millisecond-level defect detection efficiency, while the intelligent controller integrates a dedicated computing unit, forming a fully collaborative closed-loop technology chain.

The application of the Visual AI Ecosystem provides plastic bottle manufacturers with a more efficient and accurate quality inspection solution, improving product quality and competitiveness. With the continuous advancement of technology, AI visual inspection will be applied in even more fields in the future, injecting powerful impetus into the intelligent transformation of industrial production.