The application of visual inspection technology in carton coding

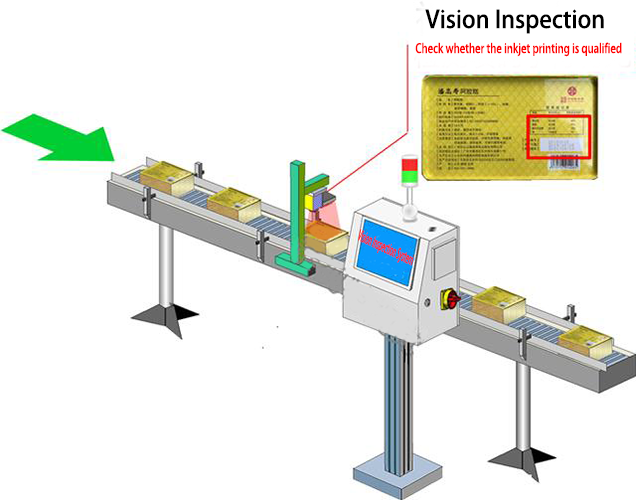

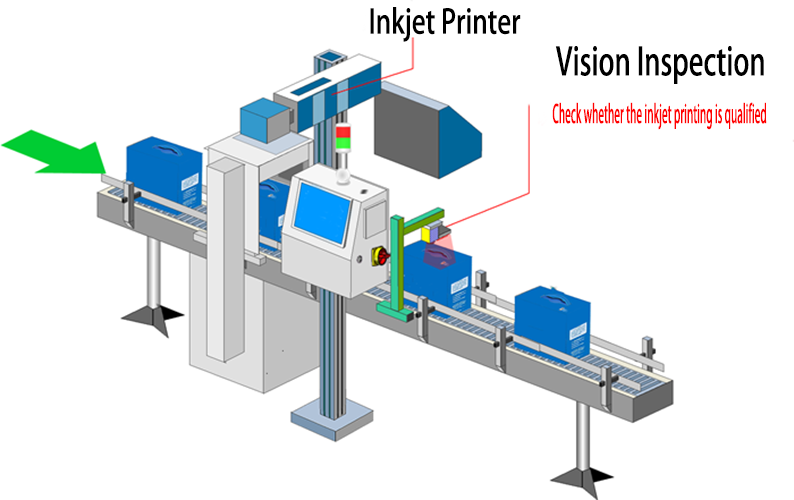

The application of visual inspection technology in carton coding is a key step in improving quality control and automation in modern industrial production. Using machine vision systems, it automatically identifies and verifies the accuracy and completeness of characters, QR codes, and other information printed on carton surfaces, effectively replacing traditional manual inspections and ensuring product quality before leaving the factory.

Application Background and Core Value

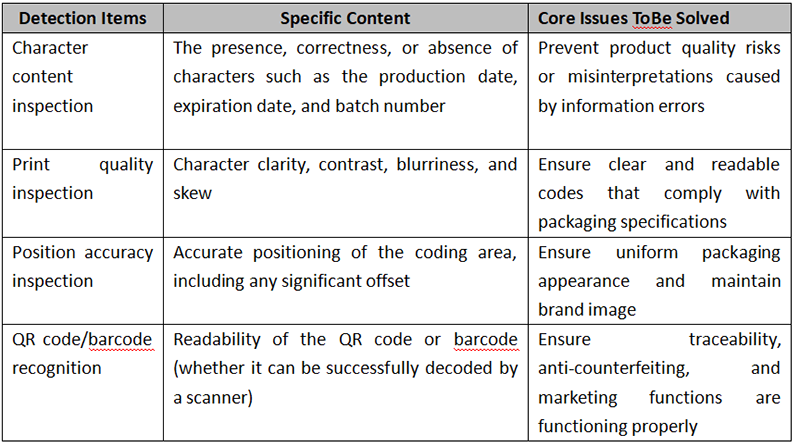

In many industries, such as food, pharmaceuticals, and daily chemicals, cartons often require printing information such as production dates, expiration dates, batch numbers, QR codes, or barcodes on their exteriors.

However, during the production process, fluctuations in raw materials, equipment conditions, or production processes can easily lead to missing or missed codes, incorrect characters, blurry characters, misaligned positions, and unreadable QR codes. Traditional visual inspection methods, which rely on workers, are not only inefficient on high-speed production lines (running hundreds of products per minute), but are also prone to missed inspections due to fatigue and negligence. Once substandard products enter the market, they can lead to consumer complaints and even severely damage a company's reputation. The introduction of visual inspection systems aims to enable 24/7, high-precision, and high-speed online automated inspection, significantly reducing quality risks. Technical Principles and System Structure

Visual inspection systems primarily rely on optical imaging and image analysis technologies. Their core workflow can be summarized as follows:

Image Acquisition: When a carton travels on a conveyor to the inspection station, a sensor triggers an industrial camera (typically a CCD or CMOS type) to take a picture. To ensure image quality, the system uses a specialized lighting source to reduce ambient light interference and ensure clear character recognition.

Image Processing: The captured image is transmitted to the vision controller (industrial personal computer). Dedicated image processing software pre-processes the image (e.g., noise reduction and contrast enhancement). It then uses optical character recognition (OCR) or optical character verification (OCV) algorithms to extract the character information from the printed code area.

Judgment and Execution: The system compares the recognized characters with pre-set correct information (e.g., a standard character library or a date and batch number stored in a database), or determines whether the QR code can be correctly decoded. Based on the judgment result (pass/fail), the system outputs a control signal. If defects are detected, the system triggers audible and visual alarms and activates a rejection mechanism (such as a pusher or tilting arm) to automatically remove defective products from the production line.

The following table summarizes the key inspection functions and value of visual inspection systems for carton coding:

Application Benefits and Future Trends

Deploying a visual inspection system can bring multiple benefits to businesses: improving quality control and minimizing missed inspections (character reading rates can reach 99.95%); improving production efficiency and adapting to high-speed production lines, capable of inspecting hundreds of products per minute; and reducing labor costs and reliance on skilled quality inspectors.

With the advancement of Industry 4.0 and smart manufacturing, visual inspection technology is becoming more deeply integrated with traceability and anti-counterfeiting systems. In the future, the application of visual inspection in carton coding will become even more intelligent and flexible, providing solid support for the digital transformation of the manufacturing industry.

We hope the above introduction provides a comprehensive understanding of the application of visual inspection in carton coding. If you are interested in further details on a specific aspect (such as camera selection or algorithm development), we can discuss this in more depth.