Analysis of the Advantages and Disadvantages of Can Vision Inspection Technology: The Path Toward Intelligent Quality Control

1. Introduction: The Importance of Can Packaging and Quality Inspection

Cans, as one of the most common packaging formats in the modern food and beverage industry, are widely used for packaging thousands of products, including carbonated beverages, beer, and milk powder. With the rapid development of packaging technology in my country's food industry, there are no fewer than 8 million secondary packaging companies, spread across various industries and regions, with the food industry experiencing the highest frequency of packaging use.

Driven by rising economic levels and changing lifestyles, demand for various pre-packaged foods has skyrocketed, directly driving the rapid development of the can packaging industry. In this context of large-scale, high-speed production, ensuring the quality of each can has become a critical issue.

Can production is capital-intensive, technologically demanding, and environmentally demanding. It often utilizes continuous, high-volume production methods, placing extremely stringent demands on visual quality.

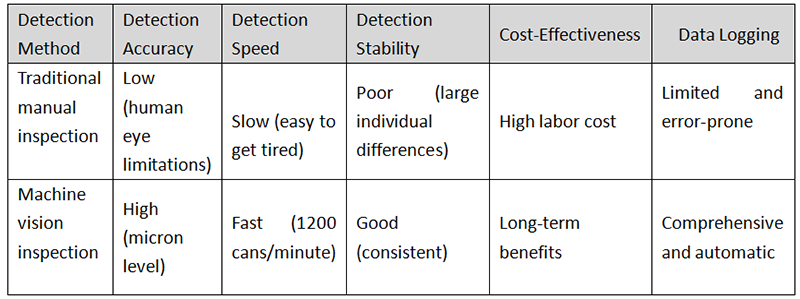

Traditional quality inspection relies heavily on manual labor, with workers performing highly repetitive inspection tasks on the assembly line. This not only incurs significant labor and management costs, but also makes it difficult to guarantee zero errors. Factors such as fatigue, individual differences, and distraction can affect the accuracy and consistency of inspection results. With the rapid development of intelligent manufacturing, automation, digitization, and informatization, machine vision inspection technology has emerged and is gradually becoming a mainstream solution for can quality inspection.

Visual inspection systems mimic human vision, using cameras to capture images and computer processing and analysis to achieve automated inspection and judgment, effectively overcoming the many limitations of manual inspection. This article will comprehensively analyze the advantages and disadvantages of can visual inspection technology, exploring its technical principles, current applications, and future development trends.

2 .Technical Principles and System Composition of Can Visual Inspection

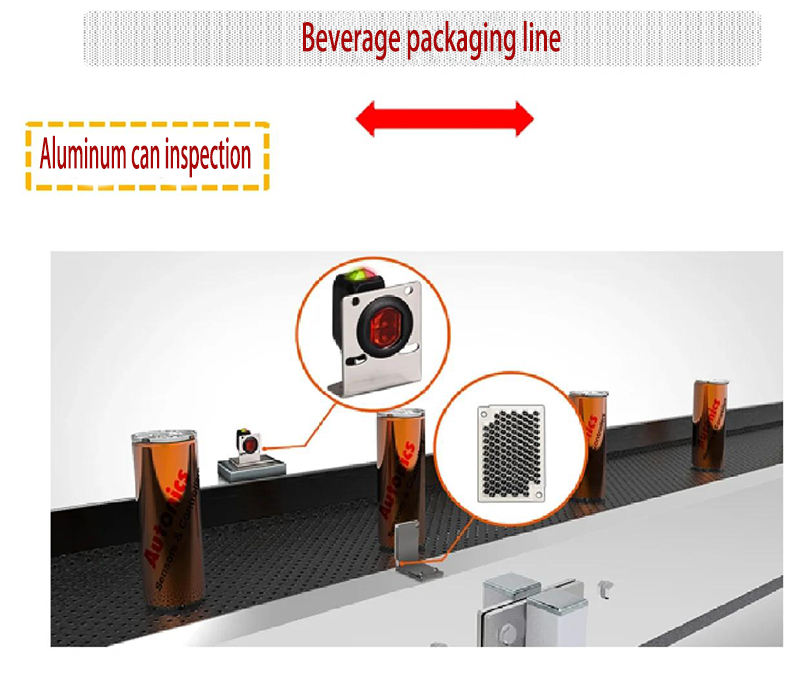

Can visual inspection technology is an automated inspection method that integrates optics, electronics, computers, and mechanical engineering. Its basic principle is to capture digital images of the can surface through an image acquisition system, then use image processing algorithms to extract feature information, and finally identify and classify defects based on preset criteria.

2.1 System Composition

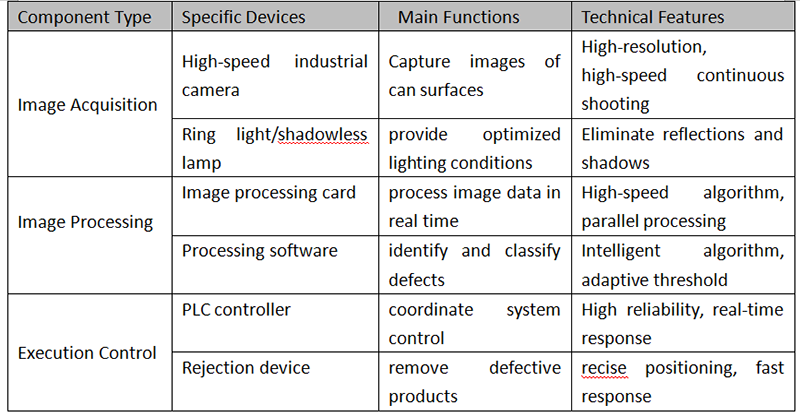

A complete can visual inspection system typically consists of three main components:

Image acquisition system: This includes components such as a high-speed industrial camera, a dedicated light source, and optical lenses. High-speed industrial cameras enable high-speed continuous shooting and high-resolution image capture, enabling the capture of surface defects and other detailed information on cans.

To address the highly reflective nature of can surfaces, systems typically employ specialized lighting designs, such as dome-shaped shadowless lighting, three-ring shadowless lighting, low-angle ring lighting, or coaxial lighting systems, effectively addressing lighting challenges.

Image processing system: This is the core of visual inspection, responsible for preprocessing, feature extraction, and defect identification of captured images. Preprocessing includes operations such as image denoising, grayscale conversion, and binarization, aiming to improve the accuracy and speed of subsequent processing.

Feature extraction involves extracting features from images that facilitate classification and identification, such as shape, size, texture, and color. Finally, the system uses a classifier model to accurately classify and identify surface defects on the cans.

Control system: This is responsible for automated control and operational monitoring of the equipment, including the human-machine interface, PLC automation program, and operational parameter monitoring. Operators can set various equipment parameters and monitor equipment status through the human-machine interface.

The control system also interacts with the rejection mechanism to automatically remove defective products.

2.2 Technical Implementation Process

The technical process for visual inspection of cans typically includes the following steps:

Image Acquisition: As cans pass through the inspection area on a conveyor belt, a photoelectric sensor triggers the camera to capture images, capturing high-quality images under a specific light source.

Image Preprocessing: Adaptive denoising algorithms and edge enhancement techniques are used to optimize image quality and reduce noise interference.

Region Localization and Segmentation: Key areas on the can, such as the mouth, body, pull tab, and inkjet printing area, are identified.

Feature Extraction and Analysis: The geometric, texture, and color features of each area are calculated.

Defect Identification and Classification: Pre-set algorithms or AI models are used to determine the presence and type of defects.

Result Output and Execution: The inspection results are transmitted to the PLC control system, triggering the rejection mechanism to remove defective products and recording the inspection data.

Table: Main Components and Functions of a Can Visual Inspection System

3 .Main Advantages of Can Visual Inspection

Can visual inspection technology offers significant advantages over traditional manual inspection in many aspects, making it indispensable in modern industrial production.

3.1 Improved Inspection Accuracy and Stability

Visual inspection systems can achieve micron-level measurement accuracy. For example, Xianyang Technology's HY-M5 device boasts an imaging accuracy of up to 0.01mm and an accuracy rate of up to 99% for defect detection information. This high-precision inspection capability enables the system to identify subtle defects imperceptible to the human eye, such as minute scratches, dents, and minor printing blemishes.

Furthermore, the visual inspection system is highly stable, unaffected by fatigue, emotion, or experience, ensuring consistent inspection standards and quality.

This is crucial for ensuring consistent product quality in large-scale production. The system also suppresses interference from ambient light and provides complete imaging even on highly reflective surfaces, resolving most current appearance inspection challenges.

3.2 Significantly Improved Production Efficiency

The visual inspection system is capable of high-speed online inspection, reaching speeds of approximately 700 inspections per hour,

or even up to 1,200 cans per minute. This speed far exceeds the efficiency of manual inspection and can perfectly match the pace of modern high-speed production lines, achieving 100% online inspection without slowing down the line.

The inspection system's real-time processing capabilities enable instant feedback of inspection results to the production line, enabling the timely detection and removal of defective products and preventing the generation of large quantities of scrap. The system also automatically generates statistical reports, helping production managers monitor quality status in real time and make quick adjustments.

3.3 Cost Reduction and Significant Economic Benefits

Although visual inspection systems require a certain initial investment, they can significantly reduce labor costs in the long term. Traditional inspection processes require hundreds of workers, while automated inspection requires only a handful of managers, significantly reducing manpower requirements.

Furthermore, the system reduces the risk of returns and brand damage due to missed inspections, providing a higher return on investment.

The non-contact measurement feature of the visual inspection system avoids wear and tear caused by contact with the test parts, extending equipment life and reducing potential secondary damage to products.

The system also helps manufacturers reduce material waste and improve resource utilization by proactively identifying quality issues.

3.4 Data Traceability and Improved Quality Management

Visual inspection systems not only detect defects but also collect and record a wealth of quality data, providing valuable information for the production process. This data can be used for statistical process control (SPC) to analyze quality trends, identify potential problems, and optimize production process parameters. Some advanced systems can also communicate with product traceability databases, enabling full-chain quality traceability from raw materials to finished products. This is particularly important for meeting food safety and quality regulatory requirements. Any issues can be quickly located and recalled, minimizing losses and risks.

Table: Comparison of Key Metrics between Traditional Manual Inspection and Visual Inspection

4. Limitations of Visual Inspection of Cans

Although visual inspection technology for cans offers many advantages, it also has limitations and challenges in practical applications that require objective understanding and response.

4.1 Limited Ability to Identify Complex Defects

Current visual inspection systems still face challenges in detecting certain complex defects. For example, scratches and stains on the sealant inside cans can affect detection accuracy due to viewing angle and occlusion. Similarly, for certain types of defects, such as slight deformations or errors in complex patterns, the system may not be able to flexibly identify them as well as experienced workers.

Light sensitivity presents another challenge. Despite the use of specialized lighting technology, processing highly reflective surfaces can still be affected by changes in ambient lighting.

This effect is particularly pronounced on high-speed production lines, where the system struggles to achieve effective real-time lighting adjustments, potentially leading to inconsistent image quality and, in turn, impacting inspection accuracy.

4.2 Technical Threshold and High Initial Investment

The initial investment cost of a visual inspection system is high, including equipment procurement, system integration, installation, and commissioning. This can be a significant burden for small and medium-sized enterprises.

Furthermore, system maintenance and updates require specialized technicians, increasing operating costs.

Many advanced visual inspection systems rely on deep learning models, which require extensive computing resources and data support. This presents a high technical barrier for enterprises with limited technical expertise.

Training these models requires large amounts of labeled data, which is time-consuming and labor-intensive, requiring specialized knowledge and experience. 4.3 Adaptability and Flexibility Challenges

Visual inspection systems often require parameter readjustment and reconfiguration when dealing with new products or specifications, lacking the flexibility and adaptability of human operators.

When product types change on a production line, the system may need to be recalibrated or even partially replaced, resulting in increased downtime and reduced production flexibility.

Furthermore, the stability and reliability of existing visual inspection systems may face challenges in extreme environmental conditions. For example, in high-temperature, high-humidity, or dusty production environments, the performance of cameras and lighting may be affected, requiring additional protective measures, further increasing system complexity and cost.

5. Future Development Trends

To overcome current limitations, can visual inspection technology is developing towards greater intelligence, efficiency, and flexibility.

The Deep Integration of Artificial Intelligence and Deep Learning: Future visual inspection systems will increasingly utilize deep learning technology, leveraging advanced algorithms such as convolutional neural networks (CNNs) and generative adversarial networks (GANs) to enhance their ability to identify complex defects. These systems can quickly adapt to new defect types through small-sample learning, reducing their reliance on large amounts of annotated data.

Application of High-Precision 3D Vision Technology: The development of 3D machine vision technology has provided a new approach to can inspection. For example, Xianyang Technology's high-speed, high-definition 3D machine vision system, the HY-M5, can capture high-precision 3D point cloud data of cans and determine the integrity of the pull tab by calculating height information, solving the depth detection problem that traditional 2D vision struggles with.

This technology also effectively suppresses ambient light interference, enabling complete imaging of highly reflective surfaces.

Multi-Technology Fusion and System Integration: Future visual inspection systems will increasingly integrate with other technologies, such as multispectral imaging, infrared detection, and laser scanning, to form collaborative multi-technology inspection solutions. This integration leverages the strengths of various technologies to achieve more comprehensive detection of various defects. Furthermore, the system will be more deeply integrated with other equipment on the production line, forming a closed-loop intelligent manufacturing system.

Miniaturization and Modular Design: To lower technical barriers and costs, visual inspection systems are trending towards miniaturization and modularization. Manufacturers are offering more flexible configuration options, enabling small and medium-sized enterprises to select the right system based on their needs and budget. The modular design also makes the system easier to upgrade and maintain, extending the equipment lifecycle.

6 Conclusion: An Inevitable Choice Towards Intelligence

As a crucial component of modern manufacturing automation, visual inspection technology for cans is gradually replacing traditional manual inspection methods with its significant advantages of high precision, high speed, and high stability. Although the technology currently has limitations in certain complex defect recognition, high-reflective surface treatment, and initial investment costs, these challenges are being gradually overcome through continuous technological innovation and optimization.

The value of visual inspection technology lies not only in improving quality control itself, but also in optimizing and intelligently upgrading the entire production system. It enables manufacturers to achieve comprehensive quality traceability, optimize production processes, and efficiently utilize resources, providing technical support for sustainable development. With the deepening advancement of Industry 4.0 and intelligent manufacturing, visual inspection technology for cans will continue to evolve and deeply integrate with other digital technologies to build a more intelligent, efficient, and reliable quality control ecosystem.

For can manufacturers, adopting visual inspection technology is no longer a choice but a necessity. Faced with increasingly fierce market competition and ever-increasing quality requirements, the early introduction and adaptation of visual inspection systems will help companies build core competitiveness and achieve high-quality, sustainable development. In the future, as technology costs decrease and ease of use increases, visual inspection technology will spread from large enterprises to small and medium-sized enterprises, promoting an overall improvement in the quality level of the entire industry.