Visual Inspection of Tetra Pak Coding: A Key Technology for Safeguarding Food Safety

On a high-speed milk production line, Tetra Pak cartons flow through at a rate of over ten per second. A visual inspection system for coding completes inspection and determination of each product's production date within 0.2 seconds—this invisible system is a critical technological barrier to consumer safety.

Food safety is a matter of vital importance to people's livelihoods, and the dairy industry is "an indispensable industry for a healthy China and a strong nation."

When we buy milk, we always pay attention to the production date and expiration date, because "once the expiration date, milk's safety is no longer guaranteed."

These production dates are not only printed on the outer packaging, but also directly on the top of the Tetra Pak.

How do we ensure these codes are clear and accurately readable? Visual inspection technology for Tetra Pak coding has become a "quality guardian" on the production line.

1. The Importance and Challenges of Tetra Pak Coding Inspection

As the mainstream packaging format for liquid foods, Tetra Pak's coding information is key to product traceability and expiration date management. Missing, blurred, or incorrect printed information such as the production date, expiration date, and batch number not only prevents consumers from identifying the product's status but also poses a food safety risk.

Tetra Pak code inspection faces multiple challenges: production lines operate at extremely high speeds, processing hundreds of packages per minute; code placement can be slightly off; packaging surfaces can reflect light; and the code itself can be blurry, incomplete, or unclear. Traditional manual inspection struggles to meet these challenges, prompting the emergence of automated visual inspection systems.

2. Composition and Technical Principles of Visual Inspection Systems

A typical machine vision system consists of five major modules: lighting, lens, camera, image acquisition, and vision processor.

Each module plays a key role in the system.

The lighting system is a crucial factor affecting input quality, highlighting features of the object being inspected and reducing background interference.

Based on the illumination method, it can be categorized as backlighting, frontlighting, structured light, and stroboscopic lighting.

For Tetra Pak code inspection, frontlighting is typically used, as it is easy to install and provides uniform illumination.

Cameras are the "eyes" of the system and can be categorized by various criteria, such as CCD cameras, CMOS cameras, line scan cameras, area scan cameras, and monochrome cameras, as well as color cameras.

Tetra Pak inspection often uses monochrome industrial area scan cameras because inkjet code inspection generally doesn't require color information, and monochrome cameras offer higher resolution and contrast.

The lens projects the inkjet code image onto the camera sensor. When selecting a lens, factors such as focal length, target height, image height, and magnification should be considered.

In practical applications, "selecting a lens that matches the field of view" and "focusing the image with a large depth of field" are crucial considerations.

The frame grabber is responsible for converting the video signal into a digital image, while the vision processor analyzes and processes the digital image. Modern systems often integrate the capture card and processor to improve processing efficiency.

3. Tetra Pak Code Inspection Workflow

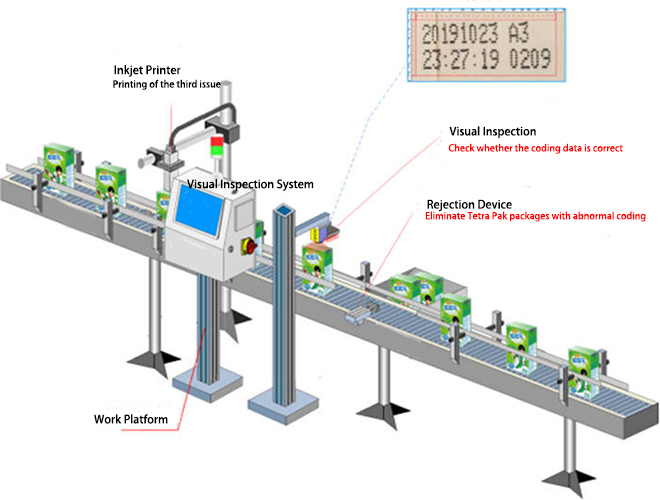

The workflow of the Tetra Pak code inspection system can be divided into three main stages.

First, an OCR character detection system is installed on the milk Tetra Pak production line to ensure that the system can cover every package passing through.

Next, when the coded Tetra Pak enters the visual inspection station, a machine vision sensor is triggered to capture an image of the three codes printed on the top of the Tetra Pak (production date, expiration date, and batch number) and send it to the system for analysis.

The system extracts and analyzes the image and compares it with the defined character image features for qualified products. If a code failure is detected, the system sends a signal to the rejection device for rejection and an alarm.

The entire process is completed in milliseconds, ensuring no impact on production line efficiency.

4 . Cutting-Edge Inspection Methods and Technological Innovation

With technological advancements, Tetra Pak code inspection methods are also constantly innovating. The dot matrix-based machine vision inspection method for code clarity achieves accurate judgment through the following steps:

The system first sets and adjusts the measurement area of the character string image through a human-machine interface and transmits the settings to the smart camera.

After capturing the character string image of the packaged product, the smart camera extracts the grayscale values of the designated color for each pixel within the dot matrix of all characters within the measurement area.

The system makes judgments based on grayscale values: if the pixel's grayscale value is less than the color grayscale white threshold (usually set to 25), it is labeled white; if it is greater than the color grayscale black threshold (usually set to 230), it is labeled black; and if it is between the two thresholds, it is labeled blurry.

Then the color area of the dot matrix is calculated. If the sum of the black pixel area and the blurry pixel area is less than the color area blank threshold (10%), the dot is labeled 0; if the black pixel area is greater than the color area solid black threshold (90%), it is labeled 1; otherwise, it is labeled blurry.

Finally, the smart camera determines the clarity: if any dot in the dot matrix is labeled blurry, the character is considered unclear. If there are no blurry dots, the dots labeled 0 and 1 are compared with the standard font dot matrix. Characters that do not match exactly are also considered unclear.

The application of deep learning technology further improves detection accuracy. A deep learning-based packaging inkjet printer inspection system uses a convolutional neural network to classify characters in images.

The system uses multiple qualified inkjet print images as training samples to train the convolutional neural network and optimize the processing module.

The extraction unit converts the inkjet print image into a black and white binary image and extracts characters based on white pixels. The comparison unit uses the trained convolutional neural network to classify the characters and compare them to obtain detection results.

5. System Implementation and Practical Considerations

When deploying a visual inspection system for Tetra Pak inkjet printing, various factors need to be considered. A professional Tetra Pak production line inkjet printing information collection device includes a housing, a photoelectric switch, a camera, and a light source.

The housing has an inspection port on the underside that matches the shape of the Tetra Pak production line. The photoelectric switch is located to the side of the production line, while the camera and light source are located above the production line.

The photoelectric switch detects the passage of a package. The camera takes a photo when a Tetra Pak passes, and the light source provides sufficient illumination for the photo.

To adapt to different production environments, this type of equipment typically features a height-adjustable design. The housing includes a main rail to which the camera and light source are detachably attached for height adjustment. The light source is typically located directly below the camera and above the Tetra Pak production line to ensure optimal lighting.

Advanced systems also feature a leveling mechanism to address situations where boxes may be tilted or at uneven heights. A deep learning-based system consists of a transport module, an acquisition module, and a processing module.

The transport module is equipped with a leveling arm and a stopper arm. When a box is transported between the two leveling arms, two pneumatic cylinders simultaneously extend inward, causing the leveling plates on both sides to clamp the box, ensuring that the coding is perpendicular to the camera angle.

When the box is transported near the camera, the stopper arm intercepts the box, keeping it relatively still relative to the camera for easy capture.

6 . Software Functionality and Data Analysis of the Inspection System

Modern Tetra Pak inkjet coding visual inspection systems not only have hardware acquisition capabilities but also powerful software features. These systems typically include modeling capabilities, allowing an unlimited number of templates to be saved to a computer and recalled for inspection at any time.

The software interface displays defect images and their specific locations on the product in real time, marking them. The display can be zoomed in at any time to identify problems promptly.

The interface also displays the current inspection speed, defect type, area, time, severity, and location.

The system's inspection parameters are divided into multiple levels and types, allowing users to adjust the inspection level for specific defect types to ensure that products with different quality standards are delivered.

The system also automatically identifies recurring defects and displays them on the interface, identifying periodic failures and prompting operators to inspect the equipment.

Data management functions enable the system to store defect results in real time and query historical records.

The system can calculate product production, scrap rate, good product rate, and the number and percentage of each defect type within scrapped products.

This data can be generated into Excel or HTML reports, with printing capabilities available.

To ensure system security, a permission management mechanism is typically implemented, with two user modes: standard and advanced. Only advanced users can set system inspection parameters, preventing misoperation by ordinary users.

7 . Application Benefits and Future Outlook

The application of the Tetra Pak inkjet code visual inspection system has brought significant benefits. It not only quickly inspects the date codes on milk Tetra Pak packages, but also promptly rejects products with unqualified date codes. This improves production efficiency and inspection accuracy while significantly reducing labor costs.

The traditional method of using a print quality sensor (PSS) to collect and inspect inkjet code information only captures grayscale signals, which are not human-readable and prevent workers from monitoring production in real time. It also cannot produce images of the codes, making it impossible to save and review them.

Modern visual inspection systems provide real-time feedback on Tetra Pak code information on the Tetra Pak production line in the form of photos, facilitating real-time monitoring of production.

The Tetra Pak code information captured by the camera can be quickly transmitted to an external monitor via wired or wireless transmission, offering rapid feedback and clear images.

With the advancement of Industry 4.0 and smart manufacturing, visual inspection technology for Tetra Pak code inspection is developing towards greater intelligence, integration, and precision. The introduction of deep learning algorithms enables the system to adaptively learn new coding fonts and patterns, continuously improving recognition accuracy.

The application of IoT technology enables seamless integration of inspection systems with other equipment on the production line, enabling data sharing and intelligent decision-making. In the future, we believe that Tetra Pak's visual code inspection technology will play an even more important role in food safety, providing consumers with more reliable quality assurance.

Tetra Pak's future code inspection technology will be even more intelligent. The integration of deep learning algorithms and artificial intelligence will enable the system to continuously optimize itself and adapt to new coding technologies and more complex production environments.

With the widespread adoption of IoT technology, visual inspection systems will no longer be isolated units, but will become key nodes in the entire smart factory data network, sharing inspection data and production status in real time, providing more comprehensive decision-making support for quality control.

These technological advances will ultimately converge towards a common goal: ensuring that every carton of milk and every bottle of beverage has a clear and traceable label, ensuring consumers' peace of mind when drinking and eating.