"Perceptive" on Automated Production Lines: An Analysis of Visual Inspection Technology for Skewed Labels

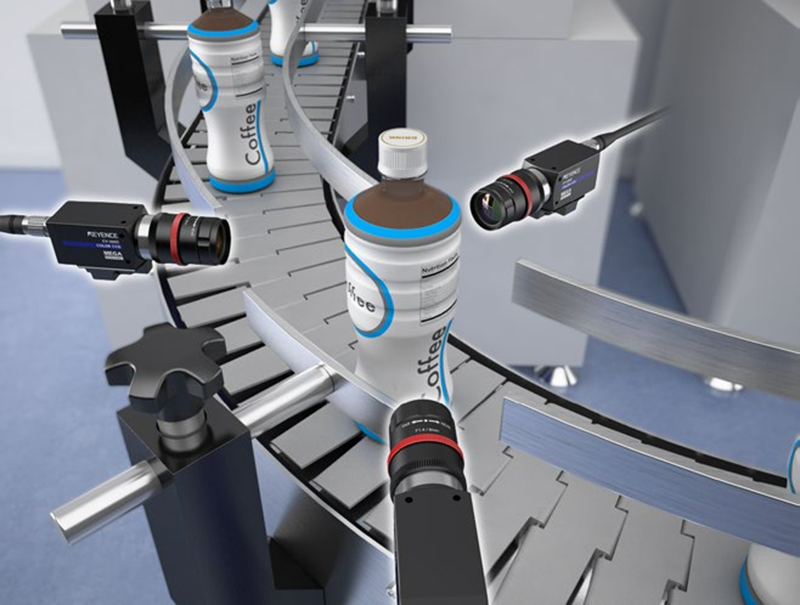

On that high-speed production line, every passing product is precisely captured. Intelligent systems achieve precise positioning at millisecond speeds, exceeding the reach of the human eye.

On automated production lines, hundreds or even thousands of products race through every minute. A small, seemingly insignificant label skew can become a critical issue that affects product aesthetics and even leads to misidentification. Traditional manual inspection has long been inadequate for high-speed production. Modern visual inspection technology, with its precision and efficiency, has become a crucial barrier to ensuring product quality.

Visual inspection systems can accurately analyze label position in a fraction of a second, promptly identifying issues and automatically rejecting defective products, significantly improving production efficiency and quality control.

1. Production Line Pain Point: Why Skewed Label Detection is Crucial

As the carrier of a product's identity, labels directly influence consumers' first impressions of it. A skewed label not only affects aesthetics but can also make product information difficult to identify and even cause quality issues.

In industries like food and pharmaceuticals, label compliance is directly related to product safety.

Traditional manual inspection methods have significant limitations. Inspectors often repeat the same task for extended periods, which can lead to visual fatigue and a significant decrease in inspection accuracy. Studies have shown that manual label inspection can miss as high as 5%-8%, and standards vary between inspectors, resulting in inconsistent inspection results.

The mismatch between high-speed production lines and inspection efficiency is another major challenge. Modern food production lines can package and transport hundreds of products per minute. Traditional inspection methods are unable to keep up with these high-speed flows, easily causing quality inspection to become a bottleneck in the production process.

The negative impact of skewed labels goes far beyond cosmetic issues. In extreme cases, if labels are applied incorrectly or skewed, they can fall off and become entangled in equipment, causing production line failures. For products requiring traceability, skewed labels can make barcodes unreadable, compromising transparency across the entire supply chain.

2.Technical Principles: How Visual Inspection Identifies Skewed Labels

The process by which visual inspection systems identify skewed labels is a sophisticated and complex one, consisting of three core stages: image acquisition, processing and analysis, and judgment output. Image acquisition is fundamental. The system utilizes an industrial-grade camera with a resolution of ≥1920×1080, paired with a high-frame-rate image sensor to accommodate the high-speed operation of the production line. Lighting system design is also crucial for obtaining high-quality images. Appropriate lighting significantly improves image quality, laying the foundation for subsequent analysis.

During the processing and analysis phase, the system extracts label features using an edge detection algorithm. This process involves preprocessing the image through grayscale conversion, noise reduction, and binarization. The Canny operator is then used to extract edges and calculate the pixel values and edge angles within the contour.

An advanced label tilt detection algorithm is as follows: The system first captures the top half of the image, locates two points on the edge of the top half of the label, and calculates the tilt angle based on these points. Using adaptive Canny edge extraction, erosion, and dilation operations, the system finds the contour with the longest perimeter, thereby determining the precise position and angle of the label.

During the output determination phase, the system compares the calculated tilt angle with a preset threshold. If the threshold is exceeded, the product is deemed defective and a signal is sent to the PLC controller, triggering a rejection mechanism to remove the defective product from the production line. Modern visual inspection systems not only determine whether labels are skewed, but also accurately calculate the angle and direction of the skew, providing real-time feedback to production lines to adjust equipment parameters and mitigate skew at the source.

3. Algorithm Evolution: From Traditional Image Processing to Deep Learning

The evolution of visual label inspection algorithms reflects continuous technological breakthroughs. Early detection methods were primarily based on traditional image processing techniques, such as template matching and edge detection.

Traditional template matching methods identify skewed labels by comparing the image to be inspected with a standard template. While simple and straightforward, this method is sensitive to environmental changes and has limited recognition accuracy. Research has shown that the accuracy of traditional template matching for label skew detection is approximately 91%, while it is as low as 72% for character anomaly detection.

With technological advances, improved template matching methods have significantly improved detection performance. Building on the traditional algorithm, this new method adds the calculation of the pixel mean within the area covered by the matching kernel, effectively reducing noise interference and increasing the accuracy of character anomaly detection to 92%, bringing the overall detection accuracy to 96%.

In recent years, the application of deep learning technology, particularly convolutional neural networks (CNNs) and the YOLO family of object detection algorithms, has advanced label detection to new heights. Trained on massive amounts of labeled samples, deep learning models are capable of identifying label defects in a variety of complex scenarios, including challenging environments like uneven lighting and complex backgrounds.

Multi-level feature fusion is another important technological innovation. Advanced detection systems simultaneously analyze edge, texture, and frequency domain features in an image, assigning different weights to each feature to form a comprehensive judgment threshold. This approach provides a more comprehensive assessment of label status and improves detection reliability.

Experimental results show that deep learning-based inspection systems achieve over 95% accuracy in identifying packaging defects and over 90% accuracy in identifying minor label misalignment (≥1mm). These systems are also immune to human subjectivity, significantly outperforming traditional methods.

4. Application Scenarios: Label Inspection Practices in Various Industries

Visual inspection technology plays a vital role in label inspection across various industries, particularly in the food and beverage, pharmaceutical, and electronics manufacturing sectors.

In the food and beverage industry, label inspection ensures product appearance conforms to standards while also ensuring traceability. Taking Jingtian's bulk water production line as an example, the system uses visual inspection technology to precisely analyze the position and angle of bottle caps, identifying and rejecting skewed caps. Multiple split-type image sensors are installed on each production line to comprehensively inspect labels on both the front and back of bottles to ensure proper label application.

The pharmaceutical industry places extremely strict demands on label accuracy, as label information is directly related to medication safety. Vision inspection systems not only detect label skew but also verify key information such as batch numbers and expiration dates to prevent mix-ups and misuse. Inspection of medicine box instructions is a typical application. The system can inspect instructions even when rotated 360 degrees, automatically rejecting the package if missing or upside down.

The electronics manufacturing sector has also benefited from visual inspection technology. In the lithium battery electrode manufacturing process, vision systems have replaced traditional color-coded sensors, detecting not only the presence of labels but also their affixed position and whether they are skewed. This is particularly important, as skewed labels can become detached and entangled in the electrode, causing production line failures.

With the diversification of packaging formats, inspection technology is constantly adapting and innovating. For barcode inspection on transparent labels, a special UV ring light is used to enhance contrast. For curved packaging, the system uses a back-projection algorithm to correct for distorted areas, ensuring accurate inspection.

5. Technical Challenges: Limitations of Current Systems and Countermeasures

Despite significant advances in visual inspection technology, practical applications still face numerous challenges.

Environmental interference is one of the main factors affecting inspection stability. Lighting variations, dust, vibration, and other conditions in the production floor can all affect image quality. To address this challenge, advanced systems use image enhancement algorithms (such as light normalization, dehazing, and dereflection processing) to improve image quality, and employ dynamic threshold adjustment technology to enable the system to adapt to varying environmental conditions in real time.

Inspection in complex backgrounds presents another major challenge. When the label and product background are similar in color or the pattern is complex, accurately identifying the label edge becomes difficult. To address this issue, multispectral imaging and 3D vision technologies are increasingly being adopted in high-end systems, improving recognition reliability by acquiring image data from multiple dimensions.

Balancing inspection speed and accuracy is also a technical challenge. High-speed production lines require systems to complete inspections within milliseconds, which can conflict with the processing time of complex algorithms. Optimization strategies include employing lightweight tracking algorithms and pixel-average-based positioning algorithms to improve processing speed while ensuring accuracy.

To address the challenges of adapting to new packaging materials, the industry has proposed "modular feature extraction" technology, which enables systems to quickly switch detection logic for different packaging types, adapting to new packaging materials and shapes without replacing core hardware.

6. Future Outlook: Development Trends in Intelligent Visual Inspection

Visual inspection technology is rapidly developing towards greater intelligence and integration, bringing new possibilities to label inspection.

The deep integration of artificial intelligence and deep learning is a major future trend. Through continuously optimized algorithms, systems will possess stronger defect recognition and analysis capabilities, enabling them to handle more complex and subtle defect detection tasks. The self-learning capabilities of deep neural networks will enable systems to adapt to changing production environments, reducing the need for manual parameter adjustment.

The Internet of Things and big data technologies are becoming closely integrated with visual inspection systems. By learning and analyzing large amounts of inspection data, the system can not only identify current defects but also predict potential quality risks, enabling predictive maintenance and quality optimization. This data-driven inspection approach will help companies shift from post-inspection to pre-emptive prevention.

The development of embedded hardware has made vision systems more compact and intelligent. Vision systems based on embedded AI can perform real-time inspections without relying on the cloud, making them more suitable for distributed deployment on production lines. Furthermore, the emergence of application-specific integrated circuits (ASICs) will significantly increase image processing speed, meeting the demands of ultra-high-speed production lines.

The application of 3D vision technology is another important development direction. By acquiring three-dimensional information about labels, the system can detect bulges and unevenness that are difficult to detect using traditional 2D vision, significantly expanding the inspection range. This technology is particularly effective for label inspection on curved packaging and irregularly shaped products.

The concept of flexible inspection platforms is emerging, whereby a single inspection system can be configured through software to adapt to the label inspection requirements of different products, enabling rapid production line switching and meeting the flexible production model of small batches and high-variety products.

With continuous technological advancements, the capabilities of visual inspection systems are continuously expanding. From simple presence/absence detection in its early days to precise angle measurement today, and on to intelligent early warning systems in the future, visual inspection technology is becoming an indispensable core component of intelligent manufacturing.

It is foreseeable that future visual inspection systems will not only serve as "gatekeepers" of quality, but will also become "collectors" of production data and "advisors" of process optimization. They will play an even more critical role in the global manufacturing industry's digital and intelligent transformation, continuously safeguarding every label on the production line and ensuring that products are presented to consumers in perfect condition.