Visual Inspection of Can Lids: Machine Vision Technology Protects Packaging Quality

On the assembly line, can lids fly by at a speed too fast for the naked eye to follow. A sophisticated vision system precisely identifies defects down to the millimeter level.

On a modern can production line, over 10 lids undergo quality inspection every second. Any tiny flaw—whether it's a scratch or dent invisible to the naked eye, or uneven sealant—can lead to spoilage or leakage.

Traditional manual inspection methods are not only inefficient but also have an accuracy rate of only approximately 70%. Automated inspection systems based on machine vision have boosted this accuracy to over 98%, revolutionizing the quality control of can packaging.

1. Technical Difficulties: Lighting, Algorithms, and the Challenges of Diverse Defects

Visual inspection of can lids has long been considered a challenging problem in the field of machine vision. The lids' round shape, metallic reflective properties, and diverse defect types make traditional inspection methods challenging. Can lid defects are primarily categorized into several categories: surface defects (pressure points, scratches, abrasions, and oil stains), structural defects (deformation, edge dents), and functional defects (uneven sealant, missing sealant, and pull-tab issues). These defects vary in size and orientation, requiring distinct inspection strategies.

The highly reflective nature of metal can lids presents a major technical obstacle. When light shines directly on a smooth metal surface, it easily produces specular reflections, resulting in overexposed and shadowed areas in the image, obscuring the desired defect features.

Image registration is also a significant challenge. Using edge regions to perform small area searches affects the accuracy and speed of region localization. Using a single image for region segmentation can also compromise accuracy, negatively impacting subsequent multi-area inspection.

2. Lighting Solution: The Key to Capturing Defects

The design of the lighting system is crucial for solving the challenges of visual inspection of can lids. Different lighting methods can highlight different types of defect features, so careful selection is required based on the inspection objectives. Direct illumination is suitable for inspecting certain surface features, but it can produce strong reflections on smooth metal surfaces, resulting in uneven image brightness and limited inspection effectiveness.

Dome lighting, which diffusely reflects light from the dome, provides more uniform illumination and is suitable for smooth surfaces. However, this type of lighting can create dark areas in the center, impacting overall inspection.

Combined brightfield and darkfield lighting is currently one of the most effective solutions. Research has shown that high-angle red light can make scratches and stains appear darker, while low-angle blue light makes scratches appear brighter. This combination can highlight both dark and light defects on can lids.

For can lids with ribbed structures, a combination of brightfield red dome lighting and darkfield blue ring lighting can be used. For basic lids, planar monochromatic diffuse lighting can be used. 3. System Architecture: From Image Capture to Defect Rejection

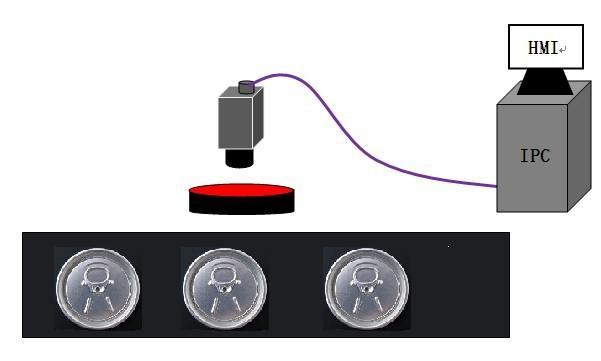

The complete can lid visual inspection system consists of multiple components working together, including a cap-lifting device, a conveyor, a light source, an image acquisition system, a vision processing system, and a defective rejection device.

Aluminum can lids are continuously fed into the conveyor area via the cap-lifting device, where they are secured to the conveyor belt using vacuum suction. As the lids pass through the imaging area, a fiber optic sensor triggers the industrial camera and light source to capture high-speed, clear images of the lids.

The advanced inspection system utilizes a composite LED light source design, integrating multiple light sources, including a three-ring shadowless light, a dome-shaped shadowless light, a low-angle ring light, and a coaxial light source. The combined control of these composite light sources produces images of the can lids with sharp outlines and vibrant color contrast.

The image processing system then analyzes the images to identify products with issues such as edge dents, surface scratches, deformed pull tabs, damaged sealant, and unclear printed text, and immediately removes them from the production line. 4. Algorithm Processing: The Intelligent Path from Image to Detection

Acquiring high-quality images is only the first step; powerful image processing algorithms are the brains of the inspection system. These algorithms need to be optimized for different defect characteristics.

The image processing process typically includes steps such as image preprocessing, image enhancement, region segmentation, and object extraction. Threshold segmentation, smoothing filtering, and edge extraction are commonly used algorithms.

Due to the significant differences in characteristics between different regions of the can lid surface, using a single image processing algorithm often fails to achieve the desired results. A combination of multiple detection algorithms tailored to the characteristics of different regions is necessary, while also considering algorithm robustness.

Angle recognition is a crucial component of defect detection, helping the system accurately identify and locate surface defects. When detecting cracks, the system uses angle to describe the crack's direction and shape; when detecting bulges or depressions, angle helps define the defect's shape and size.

Modern systems also feature self-learning capabilities, allowing them to learn and name defect types as needed and automatically set defect sizes. This ease of operation significantly enhances the system's adaptability and practicality. 5. Practical Applications: A Guardian of Efficient and Accurate Industrial Production

In real-world industrial production environments, visual inspection systems for can lids demonstrate significant advantages. For example, in a typical configuration, for a basic lid with a diameter of 110mm, the inspection speed can reach over 10 per second, with a product defect resolution of 0.1mm and an accuracy rate exceeding 98%.

These systems can detect product appearance quality defects at high speed without stopping the production line, promptly identifying and rejecting defective products. They also display inspection images in real time, automatically save defective product images, and generate statistical reports.

Visual inspection systems for empty cans have been successfully deployed on filling lines in breweries, beverage plants, and canning plants, achieving excellent inspection results. For customers with specialized needs, the equipment can be customized to meet the demands of specific production environments.

Compared to manual inspection, visual inspection systems not only significantly improve inspection efficiency and accuracy, but also operate continuously, without fatigue affecting judgment, and avoid the maintenance time and costs associated with wear and tear of mechanical components. Currently, machine vision inspection technology can identify defects as small as 0.1mm, with detection rates exceeding 10 per second and an accuracy rate exceeding 98%. As technology advances, future inspection systems will become more intelligent and adaptive, continuously learning new defect types to improve their recognition capabilities.

It is foreseeable that visual inspection systems integrating deep learning with higher-precision imaging technology will become indispensable quality assurance systems for the food and beverage packaging industry.