PET bottle inspection using machine vision perfectly creates an efficient and intelligent beverage bottle production line.

With the rise of Industry 4.0 and the advancement of automation, the concept of smart factories has begun to emerge, and unmanned production lines are becoming commonplace. PET bottle inspection machines based on machine vision technology are becoming a powerful tool for automated PET bottle inspection in beverage and other production lines, creating favorable conditions for the development of unmanned and intelligent production lines.

PET bottles are currently the mainstream packaging material for the food, beverage, and daily chemical industries. 99% of the vast majority of food and beverage bottles on the market are made of PET. In the daily chemical industry, an increasing number of cosmetics are also adopting PET bottles. PET bottles are widely acclaimed because they can be customized in various colors and have a high gloss finish. They are also lightweight, highly resistant to impact, and easy to transport. With the continuous advancement of automation in the PET beverage industry, traditional manual inspection methods are no longer able to meet the demands of high-paced, high-speed production and inspection. The use of machine vision software systems to support production has become increasingly urgent. With significantly higher efficiency, accuracy, and inspection capabilities than manual inspection, these systems have been adopted by many beverage, dairy, and daily chemical companies, enhancing production line automation.

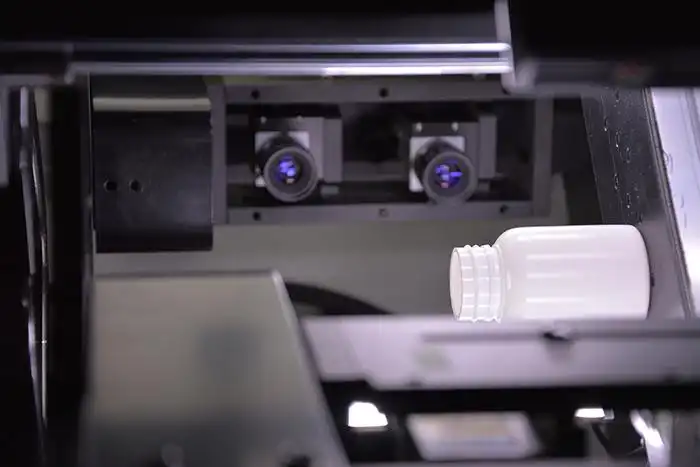

Equipped with high-performance machine vision inspection system components, these systems enable rapid, efficient, and real-time detection of various surface defects, such as black spots, dirt, burrs, uneven thickness, and even scratches, on PET bottles in pharmaceutical, beverage, and daily chemical production lines. This eliminates defective products and improves inspection efficiency.

Furthermore, powered by deep learning algorithms and trained on vast amounts of data, these systems enhance the level, accuracy, and stability of automatic recognition. These systems can detect even fuzzy features that are easily detectable by the human brain, enabling them to handle a wider range of complex inspection tasks. The inspection system can also be equipped with high-speed bottle unscramblers, case packers, and balers to achieve seamless connection with the PET bottle visual inspection system, thereby realizing full-process, automated operations from bottle unscrambling, defect detection, packaging, and case sealing. This frees employees from repetitive and tedious work and allows them to devote themselves to more valuable work, and also provides the possibility of creating unmanned and intelligent production lines.