X-ray Inspection of Beverage Bottles and Other Canned Products

X-ray Inspection of Beverage Bottles and Other Canned Products: Demonstration of Effects for Deformation, Bottle Caps, Liquid Level, Headspace, Foreign Objects, etc.

X-rays can reliably detect various container defects, including dents of various sizes, missing caps, damaged or deformed seals, etc. In terms of foreign object detection, it can identify various materials such as ferrous and non-ferrous metals, glass, rubber, hard plastics, and stones.

In modern industrial production, quality control of canned and packaged products is crucial. X-ray inspection machines, with their unique advantages, have become a key technological means to ensure product quality and safety. The system uses X-rays instead of visible light as the detection source, allowing it to penetrate the packaging to detect internal conditions and find defects and contaminants that are difficult to identify with the naked eye, regardless of their location or shape.

Main Inspection Items:

X-ray inspection of canned food - metal trim contaminants generated during the manufacturing process

X-ray inspection of contaminants in canned food

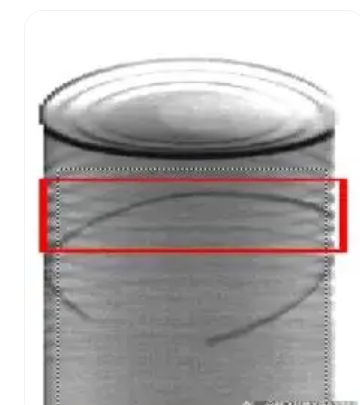

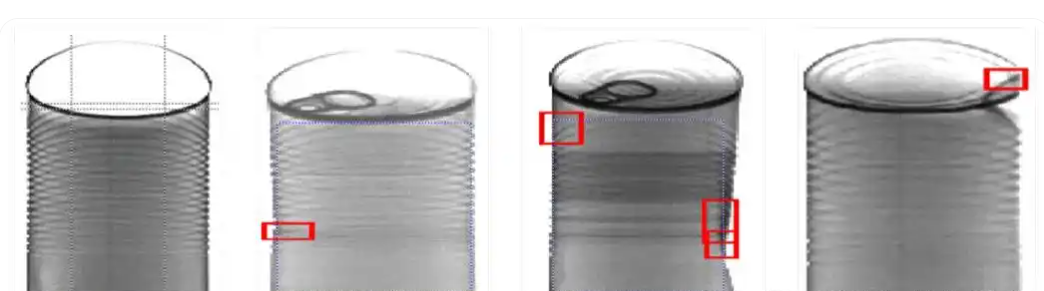

1. Container Integrity Detection

- Can body dents or deformation

- Sealing problems

- Can body edge and seam defects

- Abnormal cap installation

X-ray detection of defects in canned food: missing caps - dents - damage or deformation of the can body flange

2. Contents Detection

- Filling level

- Headspace measurement

- Product density uniformity

Whether the actual filling volume of canned food meets the standard using X-ray

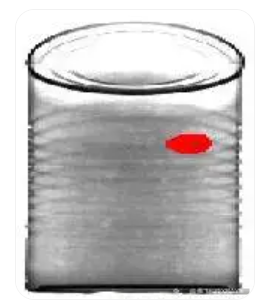

3. Foreign Object Contamination Detection

- Metal fragments introduced during the production process

- Impurities introduced from raw materials (such as stones, glass, etc.)

- Parts worn and detached from equipment

Core Advantages and Applications of the Detection System

X-ray inspection machines have unique advantages in the inspection of canned and packaged products. For metal containers or composite containers with metal components, traditional metal detection equipment is often ineffective. However, the X-ray system can not only detect metal foreign objects but also find various non-metallic contaminants. During the production process, parts of the packaging equipment may wear and detach; timely detection of these contaminants is crucial to ensuring product quality. When the X-ray detection equipment is installed after the packaging process, it can immediately detect these problems, preventing larger-scale contamination.

Detection System Advantages:

1. Non-destructive testing

- Does not affect product quality

- Enables 100% online inspection

High-precision recognition

- Multi-angle imaging

- Intelligent algorithm analysis

- Reliable defect determination

Real-time monitoring

- Immediate problem detection

- Reduces defective product output

- Supports production process optimization

Key elements of quality control

In the inspection of gas cylinders and canned products, the accuracy of the system software is extremely important. The detection software must be able to correctly identify the inherent characteristics of the container, avoiding misinterpreting normal structural features as foreign objects. At the same time, the detection range must cover the entire container to ensure there are no blind spots. For different types of containers, the system also needs to accurately measure the fill level and headspace. Especially for composite containers, due to possible variations in container size, the system needs to perform dynamic calculations and judgments based on the specific dimensions.

Comprehensive defect detection capabilities

The X-ray system can reliably detect various container defects, including dents of various sizes, missing lids, damaged or deformed seals, etc. In terms of foreign object detection, the system can identify various materials such as ferrous and non-ferrous metals, glass, rubber, hard plastics, and stones. It is particularly noteworthy that using a multi-beam X-ray detection machine can significantly improve the detection capability of low-density asymmetrical objects, providing more reliable quality control.

Best practices and production optimization

For optimal detection results, X-ray inspection should be performed immediately after the packaging process. This layout has multiple advantages: firstly, it allows for timely detection and removal of defective products, preventing them from causing equipment malfunctions in subsequent processes; secondly, it enables comprehensive monitoring of the filling and packaging process, facilitating the tracing of problem sources; finally, by detecting problems promptly, it minimizes the production of defective products. In addition, performing the inspection after the packaging process also supports automated sampling analysis, avoiding the loss of production efficiency caused by traditional offline sampling.

Continuous improvement of the production process

The X-ray inspection machine is not only a quality control tool but also an important means of production process optimization. The data collected by the system can be used to analyze production trends and identify potential problems early. For example, by monitoring changes in sealing quality, equipment maintenance needs can be predicted, and repairs can be scheduled in advance, avoiding unexpected downtime. At the same time, accurate monitoring of fill levels also helps optimize production parameters, improving production efficiency and product consistency. The application of X-ray inspection machines in the quality control of gas cylinders and canned packaging products reflects the stringent demands of modern industry on product quality.

Through the rational application of this technology, companies can significantly improve product quality, reduce production risks, and enhance production efficiency. With continuous technological advancements, X-ray inspection machines will play an increasingly important role in a wider range of applications, providing strong support for quality improvement in industrial production.

By rationally applying X-ray inspection machines, the quality and safety of gas cylinders and canned packaging products can be effectively ensured, production efficiency can be improved, and quality risks can be reduced.