How can machine vision technology improve the quality inspection of beer bottles?

Machine vision technology, by simulating human visual functions, provides a more efficient and accurate automated solution for beer bottle quality inspection, fundamentally improving the quality control level of the production line.

The table below clearly shows the application of machine vision in the inspection of various key parts of beer bottles.

| Inspection Area | Main Defect Types | Advantages of Machine Vision Technology |

| Bottle Mouth | Chips, cracks, breaks, wear, uneven opening | Can detect tiny defects that are difficult for humans to find, preventing leaky bottles from entering the market |

| Bottle Body | Bubbles, impurities, scratches, cracks, adhesions, obvious stains | Non-contact inspection, can detect subtle defects on the inner/outer wall, avoiding contact contamination and secondary damage |

| Bottle Bottom | Cracks, damage, unevenness, dirt, deposits | Precisely locates defects at the bottle bottom, effectively preventing explosion risks caused by unstable bottle bottoms |

Core Technological Aspects of Machine Vision Systems

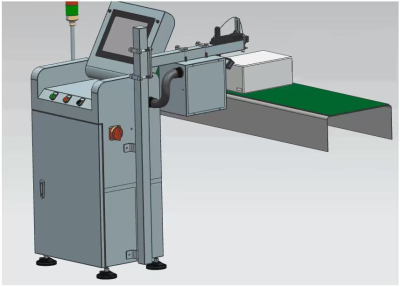

A complete machine vision inspection system mainly includes the following three aspects, which work together to ensure the accuracy and reliability of the inspection:

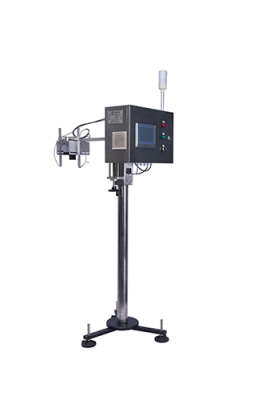

Precise Image Acquisition: This is the foundation of the system. Considering the reflective nature of glass bottles, the system uses special lighting schemes (such as ring light, flat panel light source) and multi-angle camera layouts to ensure that the acquired images are clear and have distinct features, reducing reflection interference.

Intelligent Image Processing and Analysis: The system uses a series of digital image processing algorithms (such as filtering, segmentation, edge extraction) to analyze the acquired images. By locating the center of the bottle mouth, analyzing the integrity of the edge contour, and calculating the area of stains, it accurately determines the existence and severity of defects.

Rapid Decision-Making and Execution: Once a defect is identified, the system immediately converts the result into a control signal, driving the rejection mechanism (such as pneumatic devices, robotic arms) through a PLC (Programmable Logic Controller) to remove defective products from the production line in a timely manner. Significant Advantages Compared to Manual Inspection

Machine vision technology demonstrates tremendous advantages in beer bottle quality inspection, as detailed in the comparison below:

| Comparison Dimension | Traditional Manual Inspection | Machine Vision Inspection |

| Efficiency and Speed | Slow speed, difficult to adapt to high-speed production lines of tens of thousands of bottles per hour | Extremely fast speed, can meet the inspection needs of high-speed production lines (e.g., 42,000 bottles/hour) |

| Accuracy and Stability | Easily affected by fatigue, emotions, and individual differences; inconsistent standards, poor stability | Uniform inspection standards, high accuracy (e.g., over 98% rejection rate for specific size defects), stable 24/7 operation |

| Overall Cost | High cost due to long-term investment in a large workforce | One-time investment, low long-term average cost, significant return on investment |

| Safety | Difficult to comprehensively inspect bottle necks and bottoms, posing safety hazards | Comprehensive inspection, greatly reducing safety risks and avoiding manual contact with products |

| Data Value | Difficult to perform systematic data recording and analysis | Allows for the aggregation and analysis of inspection data, providing a basis for optimizing production processes |

Future Development Trends

With technological advancements, machine vision technology for beer bottle quality inspection is developing towards a more intelligent and integrated direction:

Integration with Deep Learning: Deep learning technology (such as improved YOLO models) is being used for more complex inspection tasks, such as beer bottle brand recognition and label detection, further expanding the scope of application.

Standardization and Regulation: China has issued a national standard for "Glass Empty Bottle Inspection Machines," setting clear requirements for the equipment's detection capabilities, false detection rate, noise, and other performance aspects, promoting standardized industry development.

Hopefully, this information will help you gain a comprehensive understanding of how machine vision technology works in beer bottle quality inspection. If you would like to learn more about a specific aspect, such as image processing algorithms or lighting techniques, we can continue the discussion.