Dairy Beverage Inkjet Code Inspection Technology: A Key Line of Defense for Food Safety and Quality

Those seemingly insignificant inkjet codes are actually the first quality control checkpoint for dairy beverages entering the market.

On high-speed dairy beverage production lines, hundreds of products pass through filling, packaging, and inkjet coding every minute. The inkjet code, acting as the product's "identity card," carries critical data such as production date, batch number, and traceability information. These seemingly small characters and codes are the core of ensuring food safety and achieving full traceability.

With industry development and technological advancements, inkjet code inspection has upgraded from simple manual sampling to automated, intelligent full inspection systems, becoming an indispensable quality control link in the dairy beverage industry.

1. Industry Status: From Manual to AI-Based Inspection Transformation

The demand for inkjet code inspection in the dairy beverage industry stems from two aspects: first, regulatory compliance requirements, which mandate accurate identification of production dates and expiration dates; and second, corporate quality management needs, enabling precise traceability and management through inkjet codes.

Traditional manual inspection has significant limitations. Sampling coverage is less than 10%, and the missed detection rate for blurry barcodes can exceed 20%, failing to meet the needs of high-speed production lines. As production speed increases, the human eye can no longer keep up with the product's movement speed, resulting in high rates of misdetection and missed detection.

Currently, machine vision online inspection has become an industry trend. Dairy companies such as Yili, Mengniu, and Junlebao have taken the lead in introducing OCR character detection systems and barcode reading systems, achieving automated detection and control of inkjet code quality.

The integration of artificial intelligence technology has further driven a leap in detection capabilities. Deep learning-based image recognition algorithms can complete 100% full inspection of tiny inkjet codes on high-speed moving products in milliseconds, bringing the missed detection rate close to zero.

2. Technical Principles: The Working Mechanism of Inkjet Code Inspection Systems

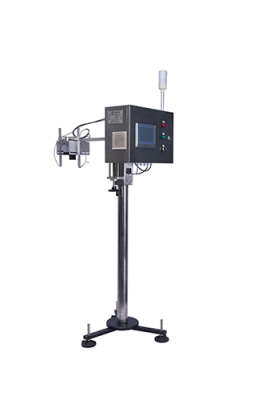

Inkjet code inspection systems are based on machine vision technology, achieving precise detection through three core links: image acquisition, signal processing, and result execution.

Image acquisition is the fundamental link. Industrial cameras capture images of the inkjet codes on the product surface triggered by sensors. To cope with different packaging materials and factory environments, the system is usually equipped with a red/blue dual-light source intelligent switching device to overcome interference factors such as reflection and curved surfaces. For special scenarios such as severe reflection from aluminum foil packaging, a blue light source can penetrate the reflective surface layer, ensuring the acquisition of clear and discernible image data.

Signal processing is the core component. The system converts the acquired image signal into a digital signal and analyzes information such as pixel distribution and brightness through a dedicated algorithm to extract character features. Modern advanced systems can even understand the logic of the printed code content, such as whether the check code is correct or whether the production date format is compliant, achieving true "content-level" quality inspection.

Result execution is the final step. When an unqualified printed code is detected, the system sends a signal to the rejection device, enabling real-time interception and alarm notification of defective products. This closed-loop control system minimizes the risk of returns caused by printing defects.

3. Application Scenarios: Practical Value in Dairy and Beverage Production

In dairy and beverage production, printed code inspection technology is mainly applied in three scenarios: three-stage printed code inspection, QR code reading and associated traceability, and anti-counterfeiting security.

Three-stage printed code inspection (production date, expiration date, batch number) is a basic application. On high-speed filling lines, the OCR character detection system can detect in real time whether the printed characters are missing, blurred, or incorrect. Taking yogurt bottle cap inspection as an example, advanced systems can achieve a recognition speed of 18,000 bottles/hour, far exceeding the efficiency of manual inspection.

QR code reading and associated traceability improve supply chain transparency. The system reads the QR code data of individual items and generates associated data for the outer carton after packaging, achieving "item-to-carton association." This traceability capability allows companies to quickly locate problematic batches, enabling precise recalls and minimizing losses.

Anti-counterfeiting security is an advanced application of printed code inspection. Advanced systems use dynamic variable encryption technology to generate encrypted QR codes containing unique product information, allowing consumers to verify authenticity by scanning the code. After a dairy company introduced this technology, the number of counterfeit product complaints decreased by 90%.

4. Implementation Guide: Selection and Deployment of Printed Code Inspection Systems

Choosing the right printed code inspection system requires considering four core dimensions: material compatibility, accuracy and speed, production environment, and compliance requirements.

Different packaging materials require different detection technology solutions. For reflective materials such as aluminum foil packaging, a system equipped with a blue light source should be selected; for heat-sensitive materials, cold processing technology should be considered to avoid deformation of the printed code.

Balancing accuracy and speed is a key decision point. Based on production line speed (such as a high-speed filling line of 600 bottles/minute) and the size of the printed characters (micro-characters or regular characters), the appropriate detection system should be selected. Higher specifications are not always better; exceeding requirements will significantly increase costs.

Environmental adaptability cannot be ignored. The high-temperature and high-humidity environment of dairy production requires equipment with a high protection rating (such as IP65) to ensure stable operation. At the same time, the equipment must comply with food industry hygiene standards to avoid product contamination.

Supplier selection should focus on technical strength and service support. Prioritize suppliers with AI self-learning capabilities and the ability to provide customized services. Also consider after-sales response speed and spare parts supply cycle to minimize production downtime risks.

5. Future Trends: Intelligent and Integrated Development

Dairy and beverage coding and inspection technology is rapidly developing towards intelligence and integration, mainly reflected in three major trends: deep integration of AI technology, integration of inspection and coding, and multi-modal sensing fusion.

Deep integration of AI technology is becoming a key engine for industry upgrading. Through machine learning algorithms, the system can dynamically optimize printing parameters to achieve zero-defect coding; it also possesses predictive maintenance capabilities, proactively warning of potential failures and transforming passive maintenance into proactive maintenance.

The integration of inspection and coding is another important trend. "Vision + AI" integrated coding workstations deeply integrate visual inspection and printing control, forming an intelligent closed-loop unit. This integrated system reduces equipment footprint, improves overall efficiency, and lowers overall costs.

Multi-modal sensing fusion enhances the comprehensiveness and accuracy of detection. By combining data from multiple sensors such as spectroscopy and 3D vision, AI's judgment of coding quality and product status will be more accurate. The popularization of edge intelligence technology allows lightweight AI models to be deployed at the production line edge, enabling low-latency real-time decision-making.

As consumer demands for food safety continue to rise, coding and inspection technology has become a core component of the quality system for dairy and beverage companies. From simple character recognition to intelligent quality assurance, the progress of coding and inspection technology directly promotes the improvement of quality control levels in the dairy and beverage industry.

In the future, with the deep integration of AI technology and the industrial internet, coding and inspection systems will go beyond single detection functions, evolving into a comprehensive industrial intelligent terminal integrating precise identification, intelligent quality inspection, full traceability, and proactive anti-counterfeiting. This evolution will provide stronger technical support for the high-quality development of the dairy and beverage industry.