Glass Bottle Liquid Level Detection Machine

1.Automatically adaptto the speed ofdifferentproduction lines,dynamic inspection

2.No radioisotope source, and uses softraydesign.Rayprotection is safe and reliable

3.Usinghardware circuit design, self-developed inspection software, high degree of optimization,fast processing speed,the maximum speed ofupto 72000 BPH

I. Equipment Parameters and Site Description

1. Project Overview

1.1 Project Name: Glass Bottle Liquid Level Online Inspection Machine

1.2 Project Description: Utilizing advanced machine vision inspection technology, this machine performs fully automatic, non-contact online inspection of glass bottle liquid level defects.

1.3 Rated Output: 1000 bottles/minute (standard configuration)

1.4 Bottle Type: Glass Bottle

1.5 Product Capacity: 100mL to 1000ml

2. Environmental Conditions

2.1 Optimum Altitude: 5-3000 meters above sea level;

2.2 Optimum Ambient Temperature: 5°C-40°C;

2.3 Optimum Ambient Humidity: 50-65% RH;

2.4 Factory Conditions: Parameters such as floor levelness and load-bearing capacity must meet relevant national standards and meet the normal operating requirements of the machine;

2.5 Storage Conditions: Upon arrival, parts and machines must be stored in a location that meets relevant national standards. During storage, proper lubrication and maintenance must be performed to prevent damage to the surface of the parts or deformation that could affect normal installation, commissioning, and operation.

3. Equipment Production Status

1). Noise Level: ≤85 dB; actual noise levels may vary depending on factors such as the containers/packaging being processed, machine power, and building acoustics.

2). Power Supply: (Power connection between the customer's main electrical cabinet and the equipment cabinet)

Power Supply: 3 x 380 AC ±10%, 50 Hz, 3 PH+N+PE.

Lighting Power Supply: 220V, 50 Hz, single-phase.

(Special voltages require prior notification; equipment specifications, delivery time, and price may vary.)

Total Power: Approximately 1.0 kW.

Control Voltage: 24 VDC.

4. Equipment Introduction

4.1 Glass Bottle Liquid Level Detector

Equipment Name: Glass Bottle Liquid Level Detector

Model: MT-RB-CYW-02

Quantity: One set

Production Speed: 1000 bottles/minute

Applicable Containers: Glass Bottles

Applicable Production Lines: Glass bottle packaging production lines with a production speed not exceeding 1000 bottles/minute

Installation Location: On a single-lane conveyor after the filler (with liquid level stratification)

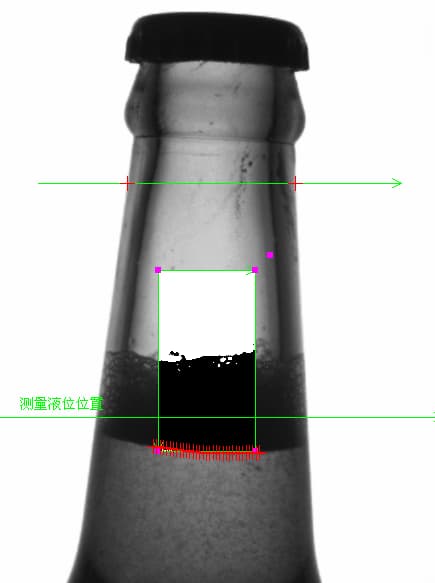

Function Description: Uses a workstation camera to take photos and analyze the liquid level in glass bottles, automatically rejecting defective products online.

Installation Location

Installation location requirements: The spacing between bottles on the conveyor line is greater than 2 cm, the conveyor line has a 2-meter-long straight track without bottle blockage, and the liquid level at the detection position is required to be stratified and a clear liquid level boundary line can be seen.

4.3 Detection Module:

4.3.1 Detection Content and Accuracy:

Test items | Detection content

| Detection accuracy

| Rejection rate

| False rejection rate

|

Liquid level test | Low liquid level detection

| ±2mm | ≥99.9% | ≤0.05% |