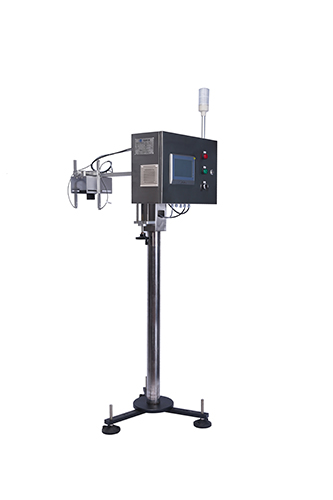

Vacuum Inspection Machine

1.With an image inspection system developed independently,

2.the maximum speed can reach 1000 cans / min.

3.Reliable detection and stable operation for long time Easy to install and easy to operate

I. Equipment Overview

1. Project Name: Filled Product Leakage Testing

2. Test Scope: Filled product leaks (leakage, missing gaskets, excess gaskets, can bulging)

3. Maximum Output: 1200 cans/minute

4. Applicable Bottle Types: Cans, three-piece cans, glass bottles, metal caps, and other flat, magnetic caps

II. Detection Principle

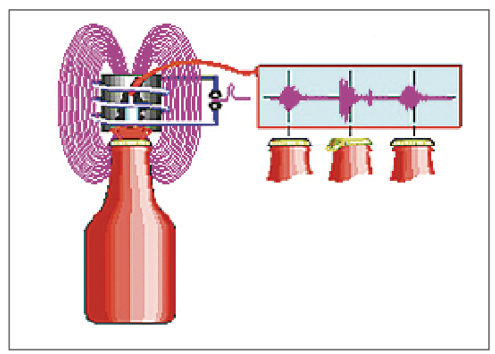

1. Utilizing magnetic pulse technology (EMP), the equipment instantly generates a directed electromagnetic pulse. When the pulse strikes the cap surface, the magnetic field causes the cap to vibrate and generate an echo. The sound acquisition device integrated into the probe collects the echo and transmits it to a processing system for analysis. Due to the internal and external pressure differential, leaking and non-leaking products will have different acoustic signatures. This principle allows for effective product leak testing.

2. Surface scanning technology is used to continuously scan the top surface of the glass bottle cap. If the seal is poor or the internal pressure of the bottle is abnormal, the surface of the glass bottle cap will change suddenly, thus determining whether the seal (or pressure) of the cap is qualified.

Electrical Control Process

III. Equipment Features:

Non-contact detection, fast inspection speed and high accuracy.

Automatically adapts to different production line speeds and performs dynamic inspection.

The main unit is designed and manufactured to be airtight, fog-proof, and water-resistant, with strong environmental adaptability.

Hardware circuit implementation and an embedded operating system ensure long-term stable operation.

Simultaneous audible and visual alarms are activated, and unqualified containers are automatically rejected.

Chinese display, LED backlit LCD, clear and bright text, and human-computer interaction operation. Large-capacity storage, capable of storing up to 10 product types, allowing users to master automated operation.

High performance-price ratio; key components are all imported from renowned brands, ensuring stable and reliable performance.

304 stainless steel chassis and brackets, with industrial protection up to IP65 rating.

Utilizes the oceanographic research institute's underwater sonar detection and sound analysis technology.

Detection Accuracy:

| No | Detection Item | Detection Conditions and Accuracy | Reject Rate | False Kick Rate |

| 1 | Leak Detection | -- -- | -- -- | < 0.03% |

| 1.1 | No Cap | No Screw Cap | >99.99% | < 0.001% |

| 1.2 | No Gasket Detection | Missing Gasket | >99.9% | < 0.001% |

| 1.3 | Double Gasket | Detection Double Gasket | >99.93% | < 0.03% |

| 1.4 | Air Leak Detection | Product Leakage | >99.99% | < 0.03% |

| 1.5 | Expansion Cans and Other Irregular Cans | -- -- | >99.9% | < 0.03% |

Note: Rapid temperature fluctuations can affect test results and cause false rejections.

IV. Installation Requirements

This equipment is installed on a horizontal, single-row conveyor chain. It consists of two components: detection and rejection. The conveyor chain must be at least 1.5 meters long (the longer the better). The chain should be kept as smooth as possible during transport. Inspection must be performed after the cooler. (Important)

1. The lid material must be magnetic. Lids from the same batch must be used during production. Mixing lids from multiple batches may reduce detection effectiveness.

2. Power supply: 220V, 50Hz AC, with a total power draw of less than 120W. Please inform us in advance if you have a different voltage standard in your country.

3. External compressed air is required for rejection, with a minimum pressure of 4 bar and a maximum pressure of 12 bar.