PET Bottle Coding Visual Inspection Technology: A Precise and Efficient Guardian of Quality

Between black and white pixels lies the intelligent eye of quality control.

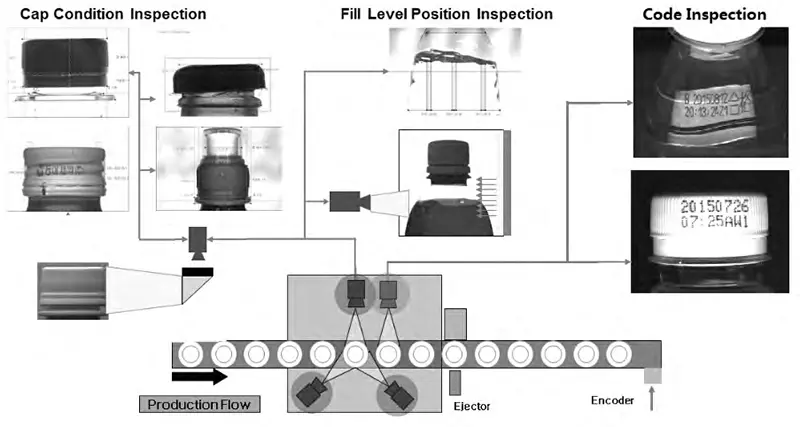

On high-speed production lines in the beverage, pharmaceutical, and daily chemical industries, PET bottles flow like flowing water. Each bottle undergoes multiple inspections, including cap tightness, liquid level, and coding quality. These inspections are completed in mere milliseconds—thanks to the advancements in modern coding visual inspection technology.

As an indispensable quality control tool in the packaging industry, PET bottle coding visual inspection systems utilize a combination of optical sensing, image processing, and artificial intelligence algorithms to achieve precise, efficient, and automated quality control.

1. Technical Principle: How Machine Vision "Reads" Coding

The working principle of a visual inspection system begins with image acquisition. When a PET bottle passes an inspection point, a photoelectric sensor triggers a high-resolution CCD or CMOS camera to capture the image, while a strobe LED light source provides illumination.

The captured image is transmitted via a data cable to an image processing industrial computer, where the system performs image preprocessing, feature extraction, and intelligent analysis. During code inspection, the system uses OCR (Optical Character Recognition) technology to verify the clarity, position, and accuracy of the code. By comparing real-time images against pre-set standards, the system can identify issues such as missing codes, missing codes, blurred codes, and incorrectly printed codes.

Inspection results are instantly transmitted to the PLC (Programmable Logic Controller). If a product with a defective code is detected, the system triggers a rejection mechanism (such as a pneumatic actuator or a sorting robot) to automatically remove the defective product from the production line.

2. System Components: Precision Collaboration of Hardware and Software

A complete PET bottle visual inspection system consists of multiple precision components. In terms of hardware, the imaging system (camera, lens, and light source) is responsible for acquiring high-quality images; the processing system (industrial computer and image processor) is responsible for analysis and judgment; and the execution system (PLC and rejection mechanism) is responsible for sorting operations.

Lighting technology is particularly critical. A suitable lighting solution can enhance the contrast between the bottle cap and the code area. Commonly used LED surface light sources have a lifespan of up to 30,000 hours. Using backlighting, they clearly outline the edges of the inspected object. Software algorithms are the "brains" of visual inspection systems. Modern inspection equipment integrates intelligent image analysis systems and expert decision-making systems, enabling multi-dimensional identification of shape, color, size, and other dimensions based on pixel distribution, brightness, color, and other information. Advanced systems also possess self-learning capabilities, continuously optimizing recognition accuracy through machine learning algorithms.

3. Performance Indicators: High-Speed, High-Precision Inspection Capabilities

Modern PET bottle inkjet inspection systems can achieve inspection speeds of up to 1,500 bottles per minute, adapting to production line conveyor speeds of ≤1.8 m/s.

In terms of accuracy, these systems can detect liquid level deviations as small as 0.5 mm and seal defects as small as microns, with extremely high accuracy in inkjet character recognition. At inspection speeds of 1,200 bottles per minute, the rejection rate for defective containers is at least 99%.

The system's robust environmental adaptability allows stable operation in temperatures ranging from 0°C to 40°C and at 95% relative humidity, meeting the installation requirements of diverse factory environments.

4. Application Scope: Multi-Dimensional Inspection Functions

The inkjet coding visual inspection system not only verifies coding quality but also integrates multiple inspection functions. Regarding cap inspection, the system can identify issues such as missing caps, skewed caps, and safety ring anomalies.

The liquid level detection function uses optical or ultrasonic technology to measure liquid levels, ensuring that fill quantities meet standards and preventing consumer complaints caused by underfilling or overfilling. The visual inspection system captures liquid level images from the front, with the portion below the liquid surface appearing black and the portion above appearing white. The system uses area compensation to identify liquid levels below the standard.

The inkjet coding inspection module verifies the clarity, position, and accuracy of information such as the production date and batch number, eliminating compliance risks caused by label errors.

5. Implementation Process: From Installation to Daily Operation

The installation and commissioning of the inspection system requires professional planning. First, the number and location of cameras must be determined based on the production line speed and bottle type characteristics. Next, parameter settings are performed, including adjusting the image positioning tool and setting the detection threshold. Daily operation is relatively simple. Operators select the appropriate bottle type inspection program via the touchscreen interface and click "Continuous Run" to start the system. Modern inspection systems feature a human-machine interactive interface with a large, clear, and bright Chinese display, making them easy to operate.

Threshold setting is crucial for ensuring inspection accuracy. The threshold is the dividing line between black and white pixels: a lower threshold value results in higher sensitivity, more accurate inspection, and a higher rejection rate; a higher threshold value results in lower sensitivity, less accurate inspection, and a lower rejection rate. Finding a balance between these two settings depends on actual production conditions.

6. Maintenance: Ensuring Stable System Operation

Regular maintenance is crucial for ensuring the long-term stability of a visual inspection system. Weekly, clean debris from the air blower, clean the inspection cabinet glass and exterior, and drain condensate from the filter valve and air reservoir.

More comprehensive maintenance is required monthly, including checking the adjustment mechanism, cleaning the sensors, and warning lights. During maintenance, please note that light source brightness settings are expressed in hexadecimal, with FF representing maximum brightness. System shutdown also follows a standardized process: first pause operations, exit system programs, select whether to shut down the image processor (select "Yes" if the entire device requires powering off), and finally turn off the main power switch.

7. Industry Value and Development Trends

Visual inspection systems create significant value for manufacturers. They reduce labor costs, replacing manual visual inspections and spot checks, reducing labor reliance and training costs. They also reduce material waste by early detecting abnormal fill volumes or coding errors, avoiding the waste of packaging materials, contents, and logistics resources.

Quality risks are effectively controlled, preventing returns, recalls, and brand damage caused by poor seals, helping companies comply with regulations such as the FDA and ISO 9001. The system also automatically generates inspection reports, recording each bottle's capping status, liquid level data, and coding information, supporting production quality traceability.

Currently, visual inspection technology for PET bottle coding is moving towards intelligence and data-driven capabilities. The integration of AI algorithms improves inspection accuracy in complex scenarios, such as reflective bottles and dynamic liquid surfaces. Industrial Internet of Things (IIoT) technology enables inspection systems to integrate with MES and ERP systems, enabling intelligent management of the entire production line.

With technological advancements, visual inspection systems are becoming increasingly powerful. Existing inspection systems can now communicate with computers via Ethernet, enabling online monitoring, online modification of inspection programs, and online recording of production data, laying the foundation for the construction of future smart factories.

Branded factories with stringent quality requirements understand that even slight packaging discrepancies can create a psychological gap for consumers and negatively impact brand image. Visual inspection systems are the silent guardians of brand reputation.