Pull Ring Cover Inspection Machine

1. Non contact online Inspection, no damage to the product

2.Fast Inspection speed, up to 60000 cans/hour at the fastest

3.360 online Inspection

4.Using customizedlight sources, shielding the interference of cover and pull ring colors on Inspection

I. Equipment Overview

1. Purpose

The system is designed for online inspection of cap quality on Yangyuan can production lines. It automatically detects and rejects defective caps to ensure product consistency and reliability.

2. Key Features

Non-contact, real-time inspection that does not damage the product.

High throughput of up to 60,000 cans per hour.

User-friendly HMI with multi-level access controls.

Industrial-grade cooling system prevents malfunctions and downtime during extended summer operations.

Customizable functions tailored to meet specific production requirements.

Automatic defect archiving, storing daily images of defective caps with adjustable storage duration.

24/7 remote monitoring and service for efficient technical support.

Continuous rejection and line stop function, ensuring production halts when defect counts exceed limits.

360° cap inspection, minimizing false rejections caused by friction or misalignment.

Zero-latency detection, reducing inspection errors from cap color or packaging variations.

II. Detection Capabilities

Verification of cap presence.

Detection of cap angle deviation (≥ 5°).

Detection of cap pop-up caused by can expansion or air leakage (≥ 1 mm).

III. Installation Requirements

The system should be installed on a 1.5–2 meter straight conveyor section directly downstream of the sealing machine.

IV. Detection Principles

Cap Pop-up Detection:

Using curved-surface scanning, the system continuously monitors the top of each can cap. Any sudden deformation due to poor sealing or abnormal internal pressure is identified as a defective seal.

Cap Angle Detection:

A Gigabit Ethernet digital camera captures top-down images of can caps. Images are analyzed using 360° template matching. Cans with angle deviations beyond the set tolerance are flagged and rejected automatically.

Inspection Workflow:

As a can passes the positioning sensor, its arrival is registered, and the control unit logs its ID and encoder value. The sensor then triggers the digital camera to capture the cap image. The image processor analyzes the data and sends the results simultaneously to the HMI (for live display) and the control unit. If a defect is identified, the control system signals the rejector to remove the corresponding can from the line in real time.

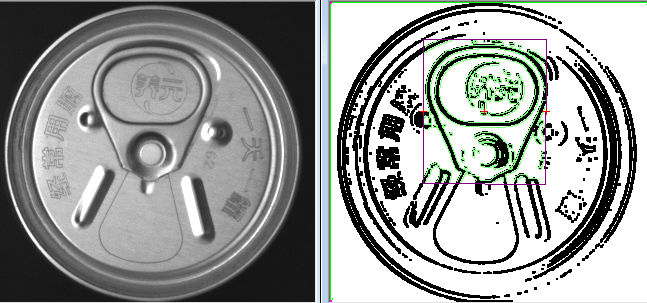

Sample image processing effect, the left is the original image, the right is the processed image

V. Equipment Configuration Details and Inspection Accuracy

(I) Detailed Equipment Description

A. Technical Parameters

Equipment Name: Can Cap Inspection Machine

Model Name: MT-YLG-PG-C1

Applicable Production Speed: 60,000 cans/hour

Inspection Area: Cap Inspection

Rejection Method: Automatically rejects cans with defective caps detected by the inspection unit

Safety Protection Rating: IP65

B. Main Applications:

Widely used in canned beverage production lines, inspecting and automatically rejecting all types of can caps.

C. Technical Features:

1. Reduces personnel and production costs

2. Improves production efficiency and product quality

3. The cap inspection machine's inspection results meet the manufacturer's relevant technical standards.

D. Detection accuracy:

Testing items | Detection content | Schematic diagram | Rejection rate

| False detection rate

| |

Bottle cap testing | No cap | ≥99.99% | <= 0.03% | ||

Cap angle offset | Bottle cap deviation angle>=5° | ≥99.9% | <= 0.03% | ||

The lid pops up (caused by bulging can or air leakage) | Deviation value>=1mm | ≥99.9% | <= 0.03% | ||

Note: The above detection accuracy is standard accuracy. The specific accuracy needs to be adjusted according to the condition of the product bottle cap and the degree of jitter of the production line. The final right of interpretation belongs to Maotong Company. | |||||

Note: The rejection rate of the test item "no bottle cap" described in the table means that out of 10,000 packages of unqualified products without bottle caps tested by the equipment, there may be 1 can that is not rejected. This is only theoretical experimental data, and the same applies to other test items.