Best Bottle Inspection Machine

Using high-speed camera to acquisiton mouth image of bottle, the processing speed is fast,up to 50000 BPH

Using 15 inch touch screen, intuitive display

Specially made bowl shaped light source is adopted, the mouth of the bottle is uniformly light, and the utility

model has the advantages of no dead angle, long service life and energy saving

The inspection machine is stable and the error rate is low

Bottle Mouth Inspection Machine

The Bottle Mouth Inspection Machine employs advanced machine vision technology to perform fully automated, non-contact online inspection of PET bottle mouth deformation and damage. The system is designed for a rated throughput of 48,000 bottles per hour and is suitable for use with both PET and PE bottles.

Environmental Conditions

Operating Altitude: 5–3000 meters above sea level

Ambient Temperature: 5°C – 40°C

Relative Humidity: 50% – 65% RH

Factory Requirements: The production facility must comply with national standards for floor levelness, load-bearing capacity, and related parameters to ensure stable machine operation.

Storage Requirements: After delivery, all equipment and components must be stored in accordance with national standards. Proper lubrication and maintenance are required during storage to prevent surface damage, corrosion, or deformation that may affect installation, commissioning, or subsequent operation.

Equipment Operating Conditions

Noise Level: ≤85 dB (actual noise may vary depending on the container or package being processed, equipment power, building acoustics, and other influencing factors).

Power Supply Connection: From the customer’s main electrical cabinet to the equipment cabinet.

Main Power: 3 × 380V AC ±10%, 50 Hz, 3PH+N+PE

Lighting Power: 220V AC, 50 Hz, single-phase

Note: Special voltage requirements must be confirmed in advance, as they may affect specifications, delivery time, and cost.

Total Power Consumption: Approx. 1.0 kW

Control Voltage: 24 VDC

Compressed Air: 4–6 bar (customer to provide piping connection from the air source to the machine).

Equipment Overview

Equipment Name: Bottle Finish Inspection Machine

Model: MT-PK021

Quantity: 1 set

Production Capacity: 48,000 bottles/hour

Compatible Containers: PET/PE bottles

Applicable Production Line: 48,000 bottles/hour PET/PE bottle packaging line

Installation Point: Located inside the blow molding machine, either at the bottle discharge position from the mold or on the conveyor chain.

Function: Detects and removes PET/PE bottles exhibiting deformation or surface damage on the bottle finish.

System working principle and process

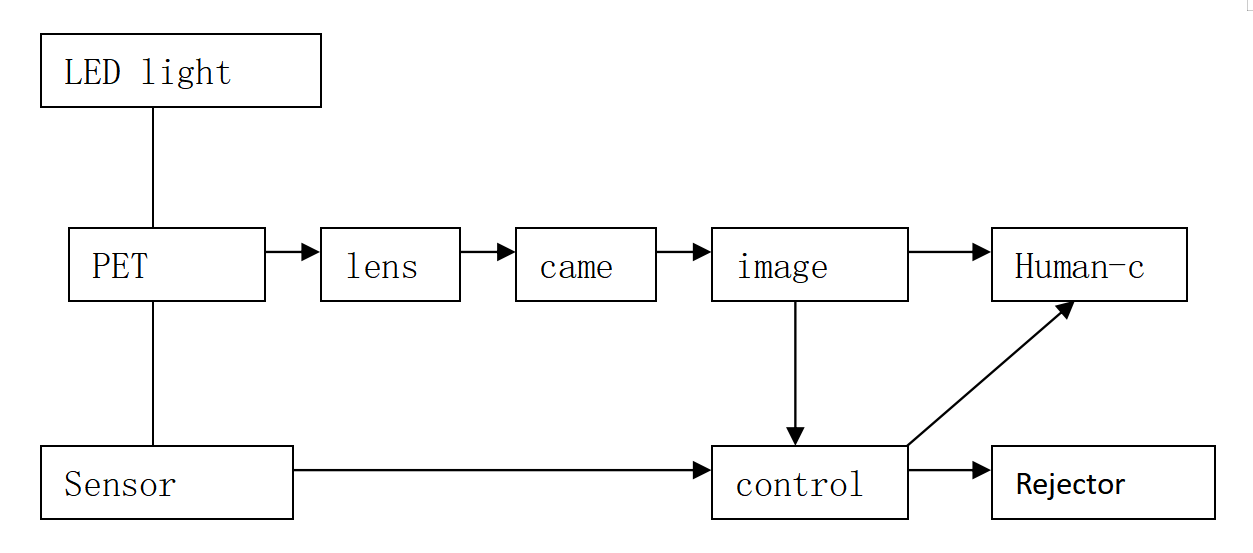

Figure 4: System working principle and flow chart

System Operating Principle and Process

As a bottle passes the positioning sensor, the sensor detects its presence and, via the control unit, records the bottle ID along with the current encoder value.

The sensor then triggers the camera to capture an image of the bottle mouth. Once the image is acquired, the image processor analyzes it and sends the results both to the human-machine interface (HMI) for real-time display and to the control unit for preparation to reject bottles with defective finishes.

When the control unit receives a rejection signal, it instructs the rejector to remove the corresponding bottle with the matching ID from the line.

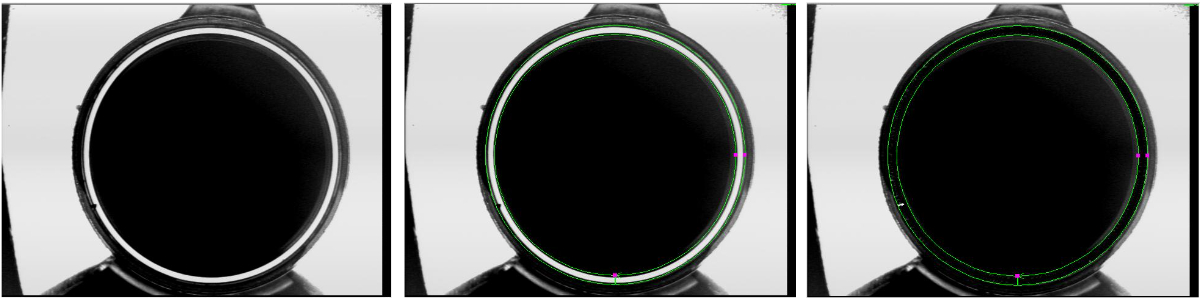

Image Acquisition Components

Light Source: Equipped with a high-longevity LED area light (service life up to 30,000 hours). Using front lighting, it provides clear visibility of the inspection area, rendering the bottle mouth as a continuous bright ring. A manual aperture, fixed-focus lens is used, where image clarity on the CCD sensor is optimized by adjusting the focus ring, and brightness is fine-tuned by adjusting the aperture ring.

Camera: Employs an area-array CCD analog camera with a resolution of 640 × 480 pixels and a frame rate of up to 60 fps, ensuring high-speed image capture and processing capability.

Bottle mouth detection module

image processing process

Test Content and Accuracy

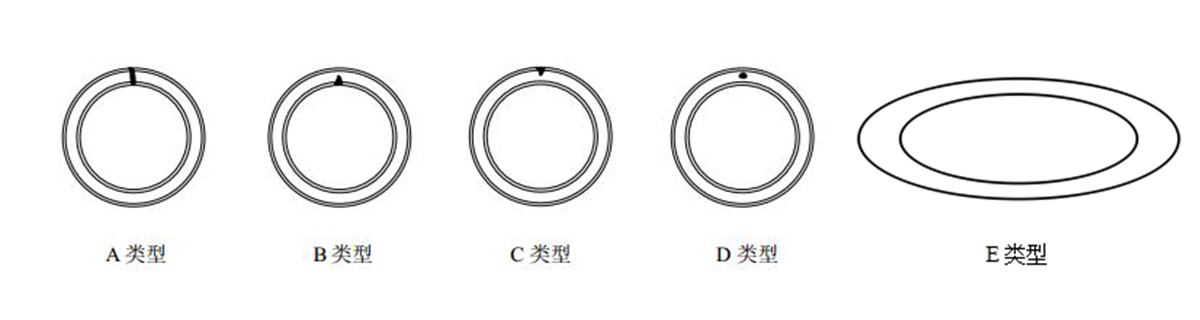

(1) Test Content

A. Through-hole

B. Internal chip

C. External chip

D. Point chip

E. Deformed bottle neck (oval)

(2) Detection Accuracy

Serial number

| Inspection Contents | Dimensions | Detection accuracy

| False rejection rate

|

1 | Penetration | Vertical section width 0.8mm, depth 0.25mm | ≥99.99% | ≤0.03% |

2 | Internal Defects | Vertical section width 0.8mm, depth 0.25mm | ≥99.95% | |

3 | External Defects | Vertical section width 0.8mm, depth 0.25mm | ≥99.95% | |

4 | Point Defects | Diameter 0.8mm, depth 0.25mm | ≥99.99% | |

5 | Neck Deformation (Oval) | Diameter difference 2mm | ≥99.95% |