Using machine vision to detect defects in beverage bottle caps.

Using machine vision for defect detection of beverage bottle caps enables efficient and precise control of product quality. The table below summarizes the main detection categories and methods, helping you quickly understand the core content.

| Detection Category | Specific Defect Types | Common Technical Methods |

| Surface Appearance Defects | Scratches, stains, damage, deformation, burrs | Image filtering, edge detection, morphological processing, threshold segmentation |

| Printing Quality Defects | Missing patterns/characters, blurring, misalignment, double printing | Template matching, contour analysis, feature extraction and comparison |

| Structural Shape Defects | High cap, crooked cap, missing cap, roundness deformation, material shortage, material overflow | Contour extraction, line fitting algorithm, size measurement |

| Sealing-related Defects | Uneven sealing surface, foreign objects, thread defects | High-precision imaging and analysis under specific lighting |

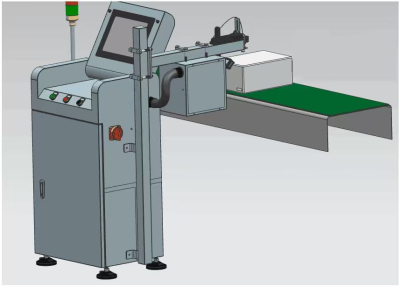

Components of a Machine Vision Detection System

A complete bottle cap defect vision detection system is like giving the machine a pair of "all-seeing eyes," which is achieved through the collaborative work of hardware and software.

• Hardware System: Mainly includes industrial cameras (such as area scan or line scan CMOS/CCD cameras), specific lenses (considering parameters such as focal length and depth of field), and the crucial lighting source (such as ring light, bar light, coaxial light, etc.). The choice of light source and lighting method is crucial for highlighting defect features. For example, low-angle ring light can effectively highlight three-dimensional scratches on the bottle cap surface.

• Software Algorithms: The software is the brain, responsible for processing the images acquired by the camera. The process usually includes image preprocessing (noise reduction, enhancement), region of interest (ROI) localization, feature extraction (such as contours, textures, geometric dimensions), and finally defect judgment through classifiers or predefined rules. Modern systems are increasingly using deep learning models, such as convolutional neural networks (CNNs), to automatically learn defect features, improving detection accuracy and generalization capabilities.

Technological Development Trends

Bottle cap defect detection technology is also constantly evolving, mainly reflected in:

• From 2D to 3D, from local to panoramic: Traditional methods are mostly based on 2D images, which may have blind spots. The latest technology attempts to use multiple cameras (such as top, bottom, and endoscope cameras) to work together to achieve 360-degree panoramic imaging of the bottle cap, completely eliminating detection blind spots. • From Traditional Algorithms to AI Deep Learning: Traditional algorithms rely on manually set thresholds and rules, resulting in low flexibility. AI-based detection methods, especially deep learning models, possess powerful feature self-learning and generalization capabilities, enabling them to adapt to different bottle cap specifications and exhibit a certain degree of adaptability to newly emerging defect types, significantly reducing debugging and maintenance costs.

• High-Speed and High-Precision Dynamic Detection: To match the high-speed pace of modern production lines, which process thousands of bottle caps per minute, advanced systems integrate high-speed triggering mechanisms (such as encoder signal synchronization), dynamic image compensation techniques (such as optical flow reconstruction), and multi-threaded parallel processing technology to ensure high precision and stability even at high speeds.

Advantages of Machine Vision

Compared to traditional manual inspection, machine vision technology offers significant advantages in bottle cap defect detection:

• High Accuracy and Stability: It can detect minute defects that are difficult for the human eye to perceive, and the detection results are objective and reliable, without fluctuations caused by fatigue.

• High Efficiency and Cost-Effectiveness: The detection speed far exceeds manual inspection, meeting the needs of high-speed production lines, and contributing to reduced labor and management costs in the long run.

• Non-Contact and Non-Destructive Testing: The entire detection process does not involve physical contact with the bottle caps, preventing secondary damage to the product.

We hope the above information helps you gain a comprehensive understanding of the application of machine vision in bottle cap defect detection. If you are particularly interested in a specific defect type (such as date code recognition or thread inspection) or technical details (such as the selection of deep learning models), we can continue to discuss them in more detail.