Pressure Testing Equipment

1.Non-contact detection, fast detection, high accuracy

2.Dynamically realize the detection of different production line speed

3.Main engine sealing design, manufacture, anti fog, waterproof, drip, environmental adaptability

4.The hardware circuit is adopted, and the embedded operating system is adopted to ensure stable operation for a long time

5.Sound,light, alarm, and automatically reject substandard containers

6.Big screen Chinese display, LED backlit night crystal, clear and bright handwriting, man-machine dialogue mode operation

7.High performance price ratio

1. Performance Overview

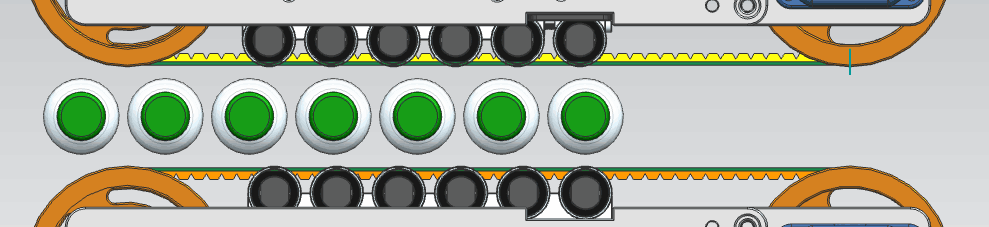

The MT-YLG-XL-C0-04 is a fully automated pressure testing system with a throughput of up to 1,200 cans per minute. It adopts a contact-based online testing method to precisely capture internal pressure characteristics, ensuring stable and highly reliable data. The system achieves superior accuracy compared to domestic and international standards. Its core technology—belt squeeze detection—is the result of over three years of dedicated development and optimization. Products are transported via a flexible belt, while side-mounted sensors measure the internal pressure of cans or bottles. The collected signals are converted into digital data by the controller and further analyzed to provide an accurate evaluation of container pressure and overall quality.

2. Applicable Containers

Aluminum cans containing liquid nitrogen

PE/PP plastic bottles filled with gas or steam

Other gas-filled containers (excluding CO₂)

3. Inspection Capabilities

Internal pressure detection

Missing lid detection

Inverted container detection

Blocked container detection

Automatic rejection of defective products according to user-defined parameters

4. Performance Specifications

Adaptive synchronization with production line speed; system halts automatically when the line stops to prevent damage from idle operation

Inspection capacity: >1,200 cans/minute

Compatible with both high- and low-pressure testing

Static accuracy: ±0.01 MPa

Dynamic accuracy: ±0.02 MPa

High resistance to high-speed impacts

Intuitive human–machine interface (HMI) operation

Real-time dynamic display of rejection data

Visual impact alarm system

Chinese-language interface

Proprietary Maotong DSP digital signal processing technology

24/7 remote technical support

Continuous rejection shutdown function

5. Detection Accuracy

Detection Range: 0.08 – 0.5 MPa

Accuracy: better than 0.01 MPa (note: excessive vertical vibration of the conveyor chain may affect accuracy)

Rejection Rate: ≥99.99%

False Rejection Rate: ≤0.01%

6. Extrusion Testing Principle

A guide mechanism at the system’s front end applies a controlled pre-squeeze to the containers, establishing an initial pressure reference. For non-leaking containers, the pressure variation measured at the tail end remains small and stable. For leaking or poorly sealed containers, however, the pressure decreases noticeably, deviating from normal levels. This method enables highly reliable detection of leaks and sealing defects.

6. Equipment detection principle

Operating Principle

As each product passes along the conveyor belt, the positioning sensor detects its presence and, via the control unit, records both the product’s identification number and the current encoder signal. The positioning sensor then activates the force sensor, which measures the instantaneous pressure exerted by the product against the belt. This pressure data is transmitted through the network to the Maotong signal processing board. The board processes and analyzes the incoming data, forwarding the results simultaneously to the human–machine interface (for real-time display) and to the control unit. If the control unit receives a rejection signal, it instructs the rejector to eliminate the product with the corresponding identification number that does not meet the pressure specifications.

II. Equipment Installation

1. Loading, Unloading, and Storage

During transportation, the equipment must be firmly secured and properly packaged to prevent damage. Particular care should be taken to ensure the sensor is not exposed to pressure or mechanical stress. The equipment exterior should be wrapped with moisture-resistant and shock-absorbing materials to avoid scratches, dents, or moisture ingress. The unit must be tightly fastened to the transport vehicle to prevent displacement or damage during transit. When unloading, use specialized lifting equipment and ensure the machine is stably fixed to the handling device to avoid slipping.

For both usage and storage, the surrounding environment must comply with the following requirements:

Relative humidity: 10%–80%

Ambient temperature: 0°C–50°C

2. Installation Requirements

2.1 Place the equipment on a flat, level surface, ensuring the clamping conveyor belt is parallel with the product’s base conveyor belt.

2.2 Before switching on the power, carefully check all cable connections for security and confirm that the control cabinet is correctly grounded.

2.3 Power Supply: Single-phase AC 220V, 50Hz, total power consumption 250W.

2.4 Compressed Air: 4–8 bar, compliant with industry standards.

2.5 For best testing accuracy, operate only after the product has cooled. The machine should be installed on a straight conveyor section of 1.5–2 meters in length.

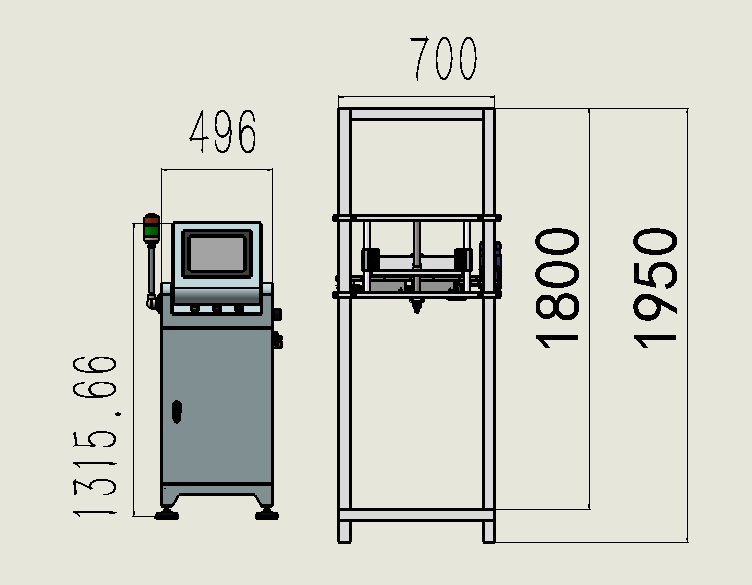

3. Equipment Structure and Specifications

Overall Dimensions: 600 × 1000 × 1700 mm

Frame Material: 304 stainless steel, integrated with conveyor

Net Weight: Approx. 100 kg

III. Safety Precautions

Please observe the following guidelines before and during operation:

3.1 Only trained personnel are authorized to operate the equipment.

3.2 Maintenance must be performed by qualified technicians.

3.3 Ensure all safety warnings and protective devices are properly installed before startup.

3.4 Do not operate the machine with the cover open. Open the cover only after disconnecting both power and compressed air.

3.5 Keep hands away from the reject cylinder’s connecting rod during operation.

3.6 Do not block or touch the photoelectric sensor during operation, as this may cause malfunction and potential injury.

3.7 Do not unplug or disconnect electrical connections while the machine is powered on.

3.8 Clearly label the equipment with warning tags during maintenance to prevent accidental startup.

3.9 Ensure both the equipment and any external devices are powered off before connecting. Restore power only after connections are secured.

3.10 Since internal components are sensitive to static electricity, both the machine frame and control cabinet must be properly grounded.

IV. Commercial Terms

Delivery: Purchaser’s production facility

Warranty: 12 months from acceptance date, maximum 14 months from shipment date

Post-Warranty Service: For two years following the warranty period, only travel and spare parts costs will apply

Preventive Maintenance: Two engineer visits per year (two days each), with only spare parts billed; requests must be submitted at least two weeks in advance by fax

Software: Lifetime free software upgrades, no hardware modifications required

Service Response: Upon written request, the supplier will dispatch service engineers to the purchaser’s site in mainland China within 72 hours