Embryo Mouth Inspection Machine

Using high-speed camera to acquisiton mouth image of bottle, the processing speed is fast,up to 50000 BPH

Using 15 inch touch screen, intuitive display

Specially made bowl shaped light source is adopted, the mouth of the bottle is uniformly light, and the utility

model has the advantages of no dead angle, long service life and energy saving

The inspection machine is stable and the error rate is low

The Bottle Mouth Inspection Machine applies advanced machine vision technology to perform fully automated, non-contact, online inspection of PET bottle mouth defects such as deformation or damage. It is designed for a rated capacity of 48,000 bottles per hour and is suitable for use with both PET and PE bottles.

Environmental Conditions

Operating Altitude: 5–3000 meters above sea level

Ambient Temperature Range: 5°C–40°C

Relative Humidity: 50%–65% RH

Factory Requirements: Floor flatness, load-bearing capacity, and other site parameters must comply with relevant national standards to ensure reliable equipment operation.

Storage Conditions: Upon delivery, all components and machines should be stored in facilities that meet national standards. During storage, adequate lubrication and maintenance must be performed to prevent surface damage, corrosion, or deformation that could impact installation, commissioning, or operation.

Equipment Operating Conditions

Noise Level: ≤85 dB (actual noise may vary depending on container type, power level, and site acoustics).

Power Connection: Provided by the customer, between the main electrical cabinet and the equipment cabinet.

Power Supply: 3 × 380 VAC ±10%, 50 Hz, 3PH + N + PE

Lighting Power: 220V, 50 Hz, single-phase

(Non-standard voltages must be confirmed in advance, as they may affect equipment specifications, delivery schedule, and pricing.)Total Power Consumption: Approx. 1.0 kW

Control Voltage: 24 VDC

Compressed Air Requirement: 4–6 bar (customer provides air pipeline connection from the source to the equipment).

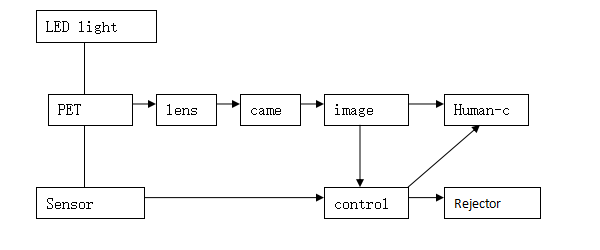

4.2 System working principle and process

Figure 4: System working principle and flow chart

System Operating Principle and Process

As each bottle passes the positioning sensor, the sensor detects its presence and the control unit records the corresponding bottle ID along with the current encoder value.

The sensor then activates the camera to capture an image of the bottle mouth. Once acquired, the image is processed by the image processor, and the results are transmitted both to the human-machine interface (HMI) for real-time display and to the control unit for rejection preparation of bottles with defective finishes.

When a defect signal is confirmed, the control unit instructs the rejector to remove the bottle associated with the recorded ID.

4.3 Image Acquisition Components

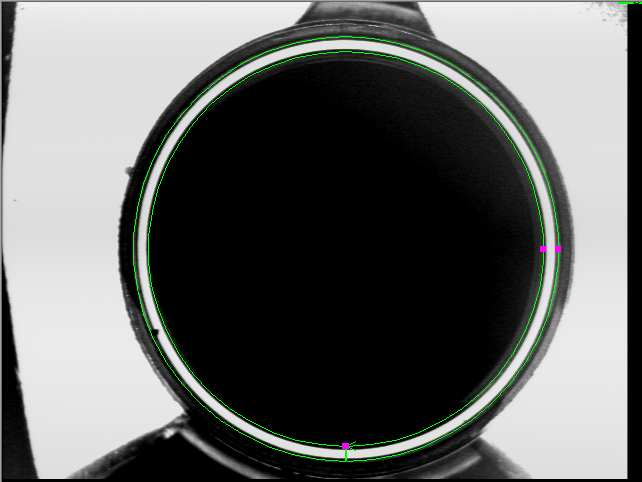

Light Source: An LED area light source with a service life of up to 30,000 hours is used. Foreground illumination ensures clear visualization of the inspection area. On the captured image, the bottle mouth appears as a continuous bright ring. A fixed-focus lens with manual aperture adjustment is employed. The focus ring is adjusted to optimize sharpness on the CCD target surface, while brightness is fine-tuned by adjusting the aperture ring.

Camera: An area array CCD analog camera is applied, offering a resolution of 640 × 480 pixels with an image capture rate of up to 60 frames per second.

4.4 Bottle mouth detection module:

image processing process

4.5 Inspection Items and Accuracy

4.5.1 Inspection Items

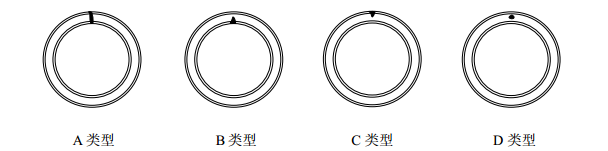

A. Presence of through-holes

B. Chipping on the inner surface of the bottle neck

C. Chipping on the outer surface of the bottle neck

D. Localized spot-type chipping

E. Bottle neck deformation (oval shape)

4.5.2 Detection Accuracy

serial number

| Inspection Contents | Dimensions | Detection accuracy

| False rejection rate

|

1 | Penetration | Vertical section width 0.8mm, depth 0.25mm | ≥99.99% | ≤0.03% |

2 | Internal Defects | Vertical section width 0.8mm, depth 0.25mm | ≥99.95% | |

3 | External Defects | Vertical section width 0.8mm, depth 0.25mm | ≥99.95% | |

4 | Point Defects | Diameter 0.8mm, depth 0.25mm | ≥99.99% | |

5 | Neck Deformation (Oval) | Diameter difference 2mm | ≥99.95% |