Air Leakage Detection Of Bagged Products

1.Using extrusion method and advanced force analysis algorithm, the fastest output can reach 400 bags / min.

2.It is suitable for nitrogen flled and other inflatable bagged food products

I. Product Introduction

1. Performance Overview

The MT-DZ-XL-S2-01 is a fully automated functional testing system designed for high-speed production lines, with a maximum inspection capacity of 300 packs per minute. Using a contact-based online detection method, it accurately measures and reflects the internal pressure characteristics of product containers, ensuring stable and reliable data acquisition. Its detection precision surpasses both domestic and international standards.

At the core of the system lies belt squeeze detection technology, refined through more than 10 years of research and field application. During conveying, a flexible clamping belt applies pressure to the product, while side-mounted sensors capture the internal pressure response. The controller then converts these measurements into digital signals, which are processed to determine the product’s internal pressure integrity and overall quality.

2. Applicable Products

The system is suitable for the inspection of:

Boxes or pouches filled with liquid nitrogen

Plastic bags containing gas or steam

Liquid-filled aluminum foil stand-up pouches

3. Inspection Capabilities

The device can effectively detect and eliminate:

Leakage due to poor sealing or defective bag seams

Abnormally low internal pressure or bag swelling

4. Performance Specifications

Automatically synchronizes with production line speed; stops with the line to avoid product rupture or bag blockage during idle operation

Inspection throughput up to 300 packs per minute

Capable of both high- and low-pressure product testing

Pressure measurement accuracy: ±0.02 MPa

High-speed impact resistance

User-friendly HMI interface

Real-time display of multiple rejection data sets

Visual alarm (light indication) for abnormal impacts

Simplified operation with a Chinese-language menu

Powered by Maotong’s proprietary DSP digital signal processing algorithm

24/7 remote support services

Automatic continuous rejection and line shutdown function for enhanced safety

serial number

| Test contents | Test Description | Rejection rate

| False rejection rate

|

1 | Bag leakage | Improper sealing or leakage caused by material jamming | ≥99.98% | ≤0.05% |

2 | Bag pressure | Bagging pressure after sealing is too low or too high, deviating from the normal value by ±0.02 MPa | ≥99.93% |

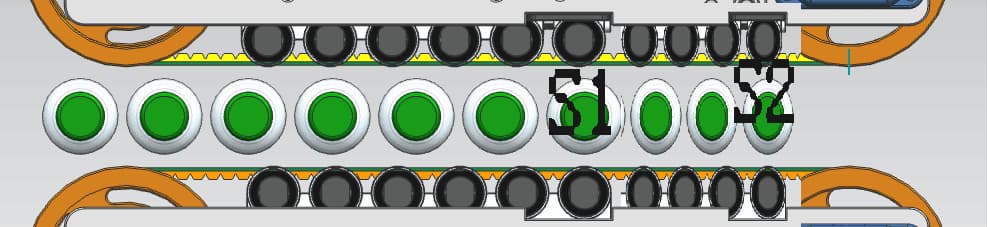

6. Schematic diagram of equipment extrusion

6. Extrusion Detection Mechanism

At the front end of the equipment, a guide mechanism is added to apply a pre-extrusion force on the product, maintaining a certain level of pressure.

If the product has a leak, the system allows the pressure to be released as much as possible, and a subsequent pressure measurement is taken at the rear end.

For intact products without leakage, the pressure change remains minimal.

For defective products with leakage or poor sealing, the pressure variation is significantly greater compared with normal products.

This principle enables the system to accurately and reliably detect leakage and sealing defects.

7. Equipment Detection Principle

When a product enters the belt, it first passes a positioning sensor, which detects its presence and records both the product’s ID and the current encoder value via the control unit. The positioning sensor then triggers the force sensor, which measures the instantaneous pressure exerted by the product against the belt.

The collected pressure data is transmitted through the network to the Maotong signal processing board, where it is processed and analyzed. The results are sent simultaneously to:

the human–machine interface (HMI) for real-time display, and

the control unit for decision-making.

If the system determines that a product does not meet the pressure standard, the control unit issues a rejection command, notifying the rejector to remove the product with the corresponding ID.

II. Equipment Installation

1. Transportation, Loading, and Storage

During transport, the equipment must be properly secured and packaged to avoid any force or tension on the sensors. The exterior must be protected with moisture-proof and impact-resistant packaging to prevent scratches, dents, and water damage. The equipment should be firmly fixed to the vehicle to avoid damage during movement.

When unloading, use specialized lifting or handling equipment and ensure the equipment is safely positioned to prevent slipping.

For storage and operation, the ambient environment must meet the following conditions:

Relative humidity: 10%–80%

Temperature: 0°C–50°C

2. Installation Requirements

2.1. Place the equipment horizontally, ensuring the clamping conveyor belt aligns parallel with the product’s bottom conveyor belt.

2.2. Before connecting power, carefully check all cables for looseness and verify the grounding wire of the rack control box.

2.3. Electrical connection: Single-phase AC 220V, 50Hz, 250W total power.

2.4. Air supply connection: Compressed air 4–8 bar, meeting relevant industry quality standards.

2.5. For best test reliability, products should be tested after cooling. The equipment should be installed on a straight conveyor section of 1.5–2m in length.

3. Equipment Structure and Appearance

3.1. Overall dimensions: as specified above

3.2. Frame: 304 stainless steel, conveyor-mounted

3.3. Weight: approx. 100 kg

III. Safety Precautions

Before operation, please carefully review the following safety guidelines:

3.1. Only trained personnel may operate the machine.

3.2. Only qualified technicians may perform maintenance.

3.3. Ensure that all safety warnings and protective devices are in place before use.

3.4. Do not operate the machine with its cover open; open the cover only when both power and compressed air are switched off.

3.5. Keep hands away from the reject cylinder linkage assembly during operation.

3.6. Avoid blocking or accidentally triggering the photoelectric switch, as this may cause the reject cylinder to misfire and risk injury.

3.7. Do not disconnect electrical connections while the system is powered on, to prevent damage to electrical components.

3.8. When servicing, clearly label the equipment to prevent accidental injury.

3.9. Before connecting external devices, ensure that both the system and external devices are powered off. Reconnect power only after cables are securely connected.

3.10. Since electronic components are sensitive to static electricity, ensure the frame and control cabinet are properly grounded.