360° Pull Ring Inspection Machine

1. Non contact online Inspection, no damage to the product

2.Fast Inspection speed, up to 60000 cans/hour at the fastest

3.360 online Inspection

4.Using customizedlight sources, shielding the interference of cover and pull ring colors on Inspection

I. Equipment Introduction

1. Purpose

This equipment is designed for online inspection of cap quality on Yangyuan can production lines, with the ability to automatically reject cans with defective caps.

2. Key Features

Non-contact, real-time inspection that does not damage the product.

High detection speed, supporting up to 60,000 cans per hour.

User-friendly human-machine interface (HMI) with multi-level access control.

Industrial-grade cooling system to ensure stable performance during prolonged summer operation.

Flexible customization to match specific production conditions.

Automatic daily photo storage of defective caps, with adjustable retention time.

24/7 remote monitoring and control capability.

Continuous rejection and shutdown mechanism (automatically halts the line after a preset number of defects).

Full 360° cap inspection, minimizing false rejects caused by can friction or handling.

Zero-delay inspection, reducing interference from variations in cap or packaging color.

II. Detection Functions

Cap presence verification

Cap angle deviation (≥5°)

Cap bulging/pop-up caused by can expansion or air leakage (≥1 mm deviation)

III. Installation Location

The system should be installed 1.5–2 meters downstream of the sealing machine on a straight section of the conveyor line.

IV. Detection Principle

Cap bulging detection:

The system applies curved surface scanning technology to continuously monitor the top surface of each can cap. If the seal is compromised or abnormal internal pressure exists, the cap surface will show a sudden variation. These changes are analyzed to determine whether the cap seal meets quality standards.

Sample image processing effect, the left is the original image, the right is the processed image

Lid angle detection principle:

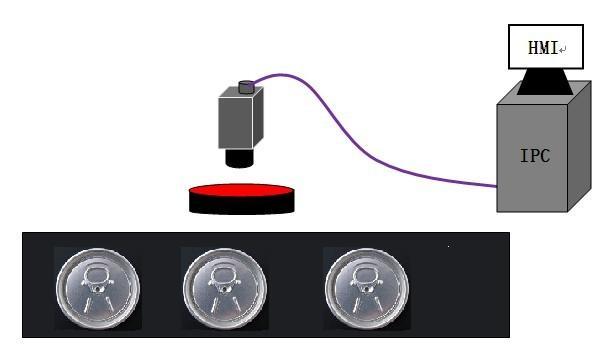

A Gigabit digital camera is used to take pictures from top to bottom to collect images of can caps. The images are digitally analyzed and matched with templates 360°. Cans with unqualified cap angles are automatically removed online.

When a can passes by a positioning sensor, it detects its arrival and the control unit records the can's identification number and the current encoder signal. The positioning sensor triggers a digital camera to capture an image of the can's cap and transmits it to the image processor via the network. The image processor processes and analyzes the received image and transmits the results to the human-machine interface for dynamic display and the control unit. Upon receiving the unqualified cap signal, the control unit notifies the rejector to remove the can with the corresponding identification number and unqualified cap online.

V. Equipment Configuration and Inspection Accuracy

(I) Detailed Equipment Description

A. Technical Specifications

Equipment Name: Can Cap Inspection Machine

Model: MT-YLG-PG-C1

Maximum Production Speed: 60,000 cans/hour

Inspection Scope: Cap quality inspection

Rejection Method: Automatic removal of cans with defective caps identified by the inspection system

Protection Rating: IP65

B. Primary Applications

This system is widely applied in canned beverage production lines, providing reliable inspection and automatic rejection of defective caps across various can types.

C. Key Features

Helps reduce labor requirements and lower production costs.

Enhances overall production efficiency and product quality.

Inspection performance fully complies with relevant technical standards set by the manufacturer.

D. Detection accuracy:

Testing items | Detection content

| Schematic diagram

| Rejection rate

| False detection rate

| |

Bottle cap testing | No cap

| ≥99.99% | <= 0.03% | ||

Cap angle offset

| Bottle cap deviation angle>=5°

| ≥99.9% | <= 0.03% | ||

The lid pops up (caused by bulging can or air leakage)

| Deviation value>=1mm

| ≥99.9% | <= 0.03% | ||

Note: The above detection accuracy is standard accuracy. The specific accuracy needs to be adjusted according to the condition of the product bottle cap and the degree of jitter of the production line. The final right of interpretation belongs to Maotong Company. | |||||

Note: The rejection rate of the test item "no bottle cap" described in the table means that out of 10,000 packages of unqualified products without bottle caps tested by the equipment, there may be 1 can that is not rejected. This is only theoretical experimental data, and the same applies to other test items.