PET Bottle Coding Visual Inspection Technology: The Intelligent Eye for Product Quality

Product lines process thousands of bottles per minute, yet a minor coding error can lead to the recall of an entire batch.

On high-speed beverage production lines, PET bottles flow through at rates of hundreds or even thousands per minute. Coding errors that are imperceptible to the naked eye—such as blurred production dates, missing batch numbers, or incorrect characters—can cause significant financial losses and brand reputation risks.

With the maturity of machine vision technology, coding visual inspection systems have become an indispensable quality safeguard for PET bottle packaging lines.

These systems ensure that every bottle's labeling information is clear, accurate, and compliant with regulations with millimeter-level accuracy and incredible speed.

1. Technical Principles and System Components

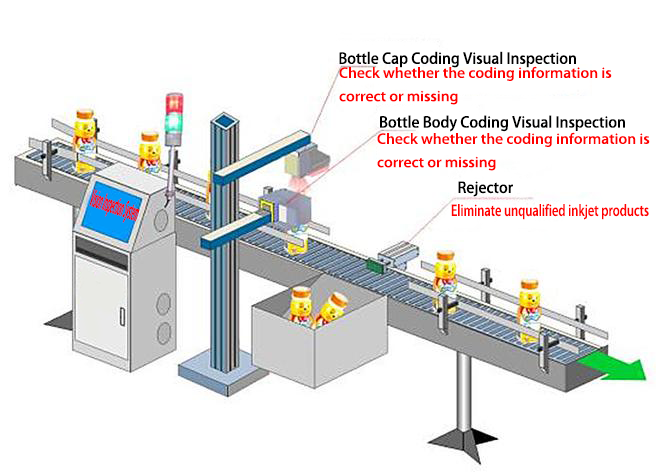

A PET bottle coding visual inspection system essentially simulates human vision. It captures the coding image through an image acquisition device, then analyzes it using advanced image processing algorithms to determine whether it is acceptable or not. The system's core operating principle can be summarized as follows: When a moving bottle triggers the detection sensor, a high-frequency flash light source momentarily illuminates the image. A camera simultaneously captures the printed image and transmits it to an image processor for processing and analysis.

After processing, the system transmits the judgment result to a programmable logic controller (PLC). If a failed print is detected, the PLC immediately sends a signal to trigger a rejection mechanism, removing the defective product from the production line.

A complete PET bottle print visual inspection system consists of several key components:

Image acquisition unit: This typically uses a high-resolution CCD or CMOS camera, responsible for capturing clear images of the printed area. These cameras require high-speed shutter speeds and interference immunity to accommodate the rapid movement of the production line and fluctuating ambient light conditions.

Illumination system: A specially designed light source ensures high-contrast images on bottles of varying materials and shapes. For highly reflective PET bottles, lighting at a specific angle is often used to reduce glare.

Image processing software: This is the brains of the system, employing OCR (Optical Character Recognition) and OCV (Optical Character Verification) algorithms to determine the clarity, position, and accuracy of printed characters. Control system: Responsible for coordinating the entire inspection process, including signal triggering, image acquisition, result evaluation, and synchronization of rejection actions.

2. Technical Advantages and Performance Indicators

Compared to traditional manual inspection, PET bottle inkjet visual inspection systems demonstrate significant advantages. In terms of inspection accuracy, modern visual inspection systems can detect liquid level deviations as small as 0.5 mm and seal defects as small as microns, even accurately identifying laser codes on slightly rotated bottles.

In terms of speed, high-end systems can inspect over 1,500 bottles per minute, or over 48,000 bottles per hour, far exceeding the capabilities of manual visual inspection.

This high-speed inspection capability enables 100% inspection of production lines, rather than traditional spot checks.

The inspection system's stability is equally impressive. Its embedded operating system and hardware circuit design ensure long-term stable operation, adapting to ambient temperatures of 0°C to 40°C and relative humidity of 95%. The sealed stainless steel housing provides industrial-grade protection against mist and water droplets. From a cost-effectiveness perspective, while visual inspection systems require an upfront investment, they can significantly reduce overall costs in the long term. Automated inspection reduces reliance on manual labor, lowers training costs, and avoids material waste and brand reputation damage caused by coding errors.

3. Application Scenarios and Challenges

Visual inspection technology for PET bottle coding has been widely used across multiple industries. In the beverage and mineral water industries, the system ensures cap seals, liquid level consistency, and coding compliance, preventing consumer complaints due to short fills or incorrect information.

In the pharmaceutical sector, visual inspection systems ensure accurate filling quantities, sterile cap seals, and batch traceability, meeting stringent regulations such as GMP.

The daily chemical industry uses the system to inspect bottle seals, liquid level accuracy, and label integrity for products such as detergents.

Despite the increasing maturity of the technology, visual inspection of PET bottle coding still faces several technical challenges:

Reflective surface interference: The reflective properties of PET bottles and caps can affect image acquisition quality, requiring specialized lighting solutions and algorithm processing. High-speed motion blur: High production line speeds can cause image blur, which requires high-frequency flash and high-speed shutter speeds.

Deformed character recognition: Characters printed on curved bottles are prone to deformation, making recognition more challenging.

Adaptability to multiple coding types: Different companies may use laser or ink coding, and the system needs to adapt to the characteristics of different coding types.

4. Implementation Key Points and Workflow

Successful implementation of a visual inspection system for PET bottle coding requires consideration of several key factors. Bottle characteristics (such as color, transparency, and shape) directly influence the design of the inspection solution.

Production environment conditions (such as temperature, humidity, and vibration) determine the required protection level of the equipment. Line speed directly influences camera selection and system architecture design.

A typical workflow includes the following steps:

System triggering: The fiber optic sensor senses when a bottle enters the inspection area and sends a signal to the image acquisition system.

Image acquisition: The trigger signal activates the light source flash and the camera to capture an image of the coding area.

Image analysis: The image processor locates, segments, and recognizes the characters, assessing their clarity, completeness, and accuracy. Result Judgment: The analysis results are compared against pre-set standards to determine whether the product is qualified.

Defective Product Rejection: For defective products, the system sends a signal to a rejection device (such as a pneumatic actuator) to remove them from the production line.

Data Recording: The system records inspection results and images, generating statistical reports to provide a basis for quality traceability.

5. Future Development Trends

Visual inspection technology for PET bottle inkjet printing is moving towards greater intelligence. The integration of AI and machine learning is significantly enhancing the capabilities of inspection systems. Through deep learning algorithms, the system can adaptively learn complex scenarios, improving its adaptability and recognition accuracy in challenging environments such as reflective bottles and dynamic liquid surfaces.

Industrial Internet of Things (IIoT) integration is another key trend. Visual inspection systems are linked with systems such as MES and ERP to achieve intelligent management of the entire production line, monitor equipment status in real time, predict maintenance needs, and optimize production parameters.

Higher speed and multi-functionality are also worthy of attention. As production speeds continue to increase, inspection systems also require higher processing speeds. At the same time, integrated inspection platforms are becoming a trend, integrating functions such as coding inspection, cap inspection, and liquid level detection into a single device, reducing production line space and improving overall efficiency.

Future coding visual inspection systems will be more flexible and adaptive, able to quickly adapt to new bottle shapes and coding formats through software adjustments, reducing the need for hardware replacement and lowering production conversion costs.

With continuous technological advancements, PET bottle coding visual inspection systems are becoming increasingly intelligent and efficient. Some leading manufacturers have integrated their inspection systems with their Manufacturing Execution Systems (MES) and Enterprise Resource Planning (ERP) systems, enabling real-time data sharing and quality traceability.

When a bottle of mineral water rolls off the production line, it has already passed the piercing eyes of a visual inspection system. Every character, every cap, and every millimeter of liquid level is meticulously inspected to ensure consumers receive a flawless product.