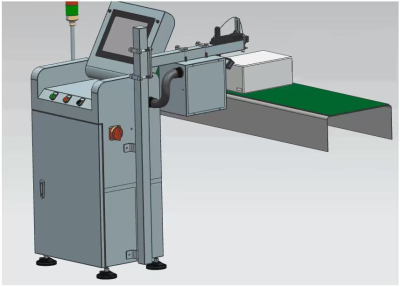

MT-LC360 Series Vision Inspection System

Appearance and Structural Damage Inspection

Label and Coding Inspection

Seal Integrity Inspection

Industry Applications

Food Industry

Label Inspection: Verify the correct placement and printing of product labels (e.g., nutritional information, batch details).

Seal Inspection: Verify the integrity of packaging for canned goods, sauces, and ready-to-eat meals to prevent leakage and contamination.

Damage Inspection: Identify scratches, dents, and gaps on cans and foil seals to ensure products can be shelved and remain fresh.

Pharmaceutical Industry

Blister Packaging Inspection: Detect tears, misalignments, and perforations in foil-sealed blister packs to ensure product quality and compliance.

Barcode and Coding Inspection: Confirm the accuracy of printed codes critical to batch tracking and regulatory requirements.

Flatness and Sealing Quality: Inspect the surface seals of medicine bags, tubes, and containers to ensure sterility and protection.

Cosmetics and Personal Care Industry

Packaging Quality Control: Detect defects in lotion, cream, and shampoo containers, such as deformation or scratches in plastic and metal packaging.

Seal Verification: Inspect the seals of pouches and tubes to ensure no leakage or tampering.

Label Alignment: Confirm labels are straight and flawless to showcase high-quality products and maintain brand integrity.

Beverage Industry (Aluminum Cans)

Can Integrity: Precisely locate minute cracks, gaps, or dents on aluminum beverage cans to prevent problems during filling or distribution.

Promotional Code Accuracy: Ensure the correct placement and readability of promotional QR codes or printed batch information.

Surface Inspection: Scan for scratches or damage on the exterior of the can to maintain the product and brand's presentation.