Can leak detection machine

1.Non contact detection, high speed, high precision

2. Adapt to the speed of production line and detect dynamically

3.Advanced sound processing technology

4.Advanced exciting circuit, providing high energy magnetic field

I. Equipment Overview

Project Title: Filled Product Leakage Detection System

Inspection Scope: Detection of filled product defects, including leakage, missing gaskets, excessive gaskets, and can deformation (bulging).

Maximum Throughput: Up to 1,200 cans per minute.

Applicable Container Types: Suitable for cans, three-piece cans, glass bottles, metal caps, and other flat, magnetically responsive caps (refer to illustration below).

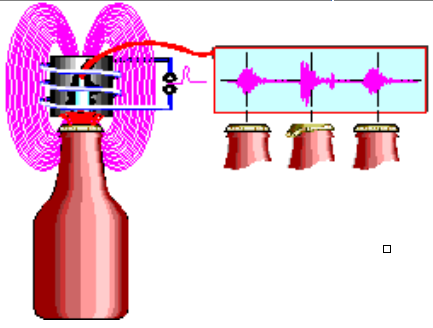

II. Detection Principle

The system employs electromagnetic pulse (EMP) technology, which generates a focused electromagnetic pulse in an instant. When the pulse interacts with the container lid, it induces a micro-vibration of the surface, producing an acoustic echo. The probe’s built-in sound acquisition unit captures this echo and transfers the signal to the processing system for analysis. Because sealed and leaking products exhibit different acoustic responses due to internal and external pressure differences, the system can accurately identify sealing defects and verify product integrity.

2. Detection Method

The system applies surface scanning technology to continuously monitor the top surface of the glass bottle cap. When the sealing is inadequate or the internal pressure is abnormal, the cap surface will undergo a sudden change. By detecting these variations, the system can accurately determine whether the sealing or pressure condition of the cap meets the required standards.

III. Equipment Features

Non-contact inspection with high speed and precision.

Adaptive detection that automatically adjusts to different production line speeds.

Sealed and durable design, resistant to moisture, fog, and water, ensuring strong adaptability to harsh environments.

Stable performance, achieved through hardware-based circuit design combined with an embedded operating system.

Dual alarm system with both sound and light signals, coupled with automatic rejection of defective containers.

User-friendly interface with Chinese-language display, LED backlit LCD, and intuitive interactive operation.

Flexible data storage, supporting up to 10 product configurations to facilitate automated and efficient production.

High reliability, with core components sourced from internationally recognized brands to ensure stable operation.

Robust construction, featuring a 304 stainless steel frame and brackets with an industrial protection level up to IP65.

Advanced technology foundation, utilizing sonar detection and acoustic analysis methods originally developed by the Institute of Oceanography.

Detection accuracy:

serial number

| Test Items | Testing Conditions and Accuracy | Rejection rate

| False kick rate

|

1 | Leakage test | -- | -- | < 0.03% |

1.1 | No lid | No screw cap | >99.99% | |

1.2 | No gasket test | Missing rubber gasket | >99.9% | |

1.3 | Double gasket test | Double rubber gasket | >99.93% | |

1.4 | Air leak test | Product leakage | >99.99% | |

1.5 | Expansion cans and other special-shaped cans | >99.9% |

Note: Rapid temperature changes will affect the detection results and cause false rejections.

V. Installation Requirements

This system is designed for installation on a horizontal, single-row conveyor chain and is composed of two modules: detection and rejection. The conveyor chain should have a minimum length of 1.5 meters (longer is recommended) to ensure stable operation. During conveying, the chain plate must remain steady, and the equipment should be positioned after the cooler for inspection purposes. (Critical requirement)

Installation Notes:

The bottle caps must be magnetic and produced from the same batch during operation. Mixing caps from different batches may adversely affect detection accuracy.

Power requirements: 220V AC, 50Hz, with a total power consumption of less than 120W. For facilities using different voltage standards (e.g., in overseas installations), prior notification is required.

Rejection functionality requires an external compressed air supply with a pressure range of 4–12 bar.