Can Liquid Level Detection Machine

1.Automatically adapt to the speed of different production lines, dynamic inspection

2.No radioisotope source, and uses soft ray design.Ray protection is safe and reliable

3.Using hardware circuit design, self-developed inspection software, high degree of optimization,fast processing speed, the maximum speed of up to 72000 BPH

I. Project Overview

Project Title: Liquid Level Detection System

Project Scope: Online detection of product liquid levels with precise rejection of non-conforming containers.

Maximum Capacity: Up to 72,000 bottles/cans per hour (high-end model).

Applicable Container Materials: Aluminum, tinplate, PE/PET/PP plastics, ceramics, glass, and other common packaging materials.

Product Specifications: Volume range 200–2000 ml; diameter 30–90 mm; height 50–200 mm.

Equipment Model: MT-HFX-06.

II. Environmental Conditions

Applicable Altitude: 5–3,000 meters above sea level

Ambient Temperature Range: 5°C–40°C

Relative Humidity: 50%–65% RH

Factory Requirements: Floor flatness, load-bearing capacity, and other infrastructure conditions must conform to relevant national standards to guarantee stable and proper operation of the equipment.

Storage Conditions: Upon delivery, the equipment and its components shall be stored in accordance with national standards. During the storage period, appropriate lubrication and maintenance measures should be implemented to avoid surface damage or deformation that might affect subsequent installation, commissioning, and operational performance.

III. Production Requirements

Power Supply: 220V, 50Hz, single-phase (to be provided by the customer). Special voltage requirements must be notified in advance, as they may impact equipment configuration, delivery time, and pricing.

Total Power Consumption: Approximately 1.0 kW

Control Voltage: 24 VDC

Compressed Air: 4–12 Pa (the customer is responsible for providing the connection pipeline from the air source to the main equipment unit)

IV. Equipment Introduction

1. Installation Plan

Location: Installed downstream of the filling machine, either before or after the inkjet printer.

Requirements: Must be mounted on a single-row conveyor chain, with a straight section of at least 2 meters reserved at the installation site.

Timeline: Installation work shall be completed within 24 hours.

Track Adjustment: A guardrail opening (≤15 cm) needs to be cut in the straight chain section to facilitate the discharge of defective containers by the rejector.

System Composition: The equipment is mainly composed of an inspection unit, rejection unit, power distribution cabinet, HMI, electronic modules, and mechanical assemblies.

Rejected Container Collection: It is recommended that the purchaser install a rigid container at the rejection point to collect defective products.

2. Inspection Functions

High liquid level detection (auxiliary function)

Low liquid level detection (standard function)

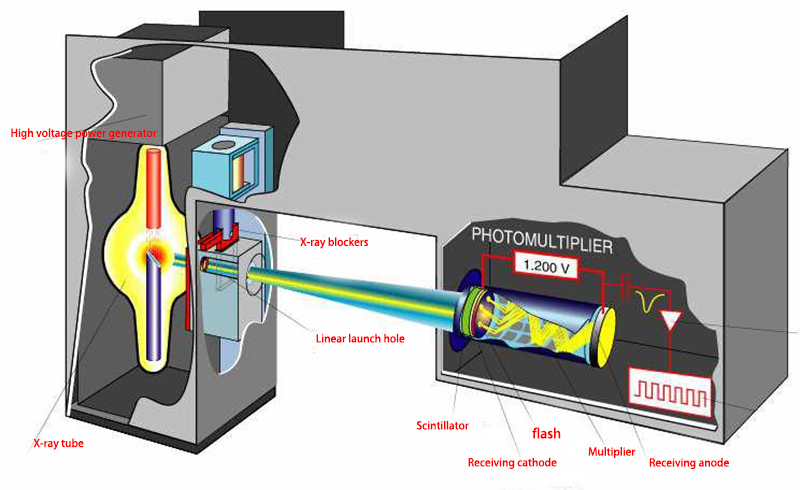

3. Detection Principle

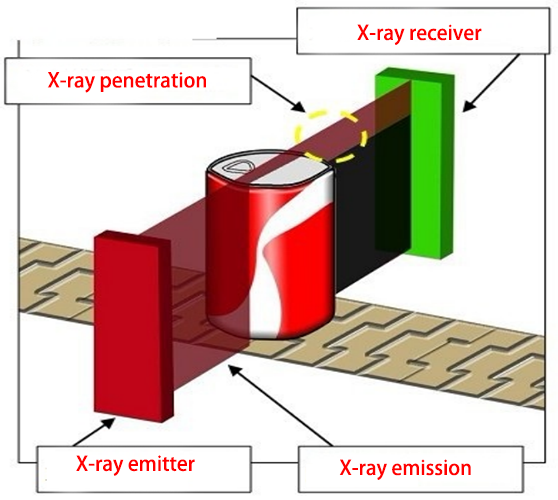

The system operates based on the X-ray penetration principle. Containers with different liquid levels generate distinct projections at the receiving end, leading to measurable numerical discrepancies. These signals are compared with user-defined standard parameters, and products identified as defective are automatically removed by the rejection system.

4. Key Features

Non-contact online inspection, causing no damage to containers.

Bottle counting is performed by an encoder on the synchronous motor, ensuring rejection accuracy remains unaffected by production line stoppages or speed fluctuations.

Adapts to varying production line speeds for dynamic real-time inspection.

Independent inspection and control cabinets reduce electromagnetic interference, ensuring stable equipment operation.

Stainless steel housing with a sealed design, resistant to fog and water droplets, making it suitable for harsh working environments.

Automatic shutdown of X-ray emission during idle periods for safety and energy conservation.

Hardware-based circuitry integrated with an embedded operating system, ensuring long-term stable performance.

Built-in audible and visual alarm system, combined with automatic rejection of defective containers.

5. Technical Specifications

Conveyor Speed: ≤1.6 m/s

Container Diameter: 20–120 mm (equipment model selection is determined by material density and container size)

Dynamic Resolution: ±1.5 mm (may be affected by foam or liquid turbulence)

Static Resolution: ±1 mm

Rejection Accuracy: ≥99.99% at an inspection speed of 400 containers per minute

Operating Conditions:

Ambient Temperature: 0°C–40°C

Relative Humidity: ≤95% (at 40°C)

Power Supply: 220V ±20V, 50Hz

A Gigabit digital camera is employed to capture images of can caps from a top-down perspective. The collected images undergo digital analysis and 360° template matching. Cans with unqualified cap angles are automatically rejected online in real time.

When a can passes the positioning sensor, the sensor detects its arrival, and the control unit records the can’s ID and the current encoder signal. The positioning sensor then triggers the digital camera to capture an image of the can cap, which is transmitted to the image processor via a network. The image processor processes and analyzes the received image, and sends the results to both the human-machine interface (HMI) for dynamic display and the control unit. Upon receiving the signal indicating an unqualified cap, the control unit instructs the rejector to remove the corresponding can with the defective cap from the production line automatically.

V. Equipment Configuration Details and Inspection Accuracy

(I) Detailed Equipment Description

A. Technical Parameters

Equipment Name: Can Cap Inspection Machine

Model Name: MT-YLG-PG-C1

Applicable Production Speed: 60,000 cans per hour

Inspection Area: Cap Inspection

Rejection Method: Automatic rejection of cans with defective caps identified by the inspection unit

Safety Protection Rating: IP65

B. Main Applications

Widely applied in canned beverage production lines for inspecting various types of can caps and automatically rejecting defective ones.

C. Technical Features

Reduces labor input and overall production costs

Enhances production efficiency and product quality

The inspection results of the cap inspection machine comply with the relevant technical standards of the manufacturer