Can Vacuum Inspection Machine

1.Non contact detection, high speed, high precision

2. Adapt to the speed of production line and detect dynamically

3.Advanced sound processing technology

4.Advanced exciting circuit, providing high energy magnetic field

I. Equipment Overview

Project Title: Online Inspection for Filled Product Leakage

Inspection Scope: Detection of leakage-related defects, including liquid leakage, missing gaskets, excess gaskets, and bulging cans.

Maximum Throughput: Up to 1,200 cans per minute.

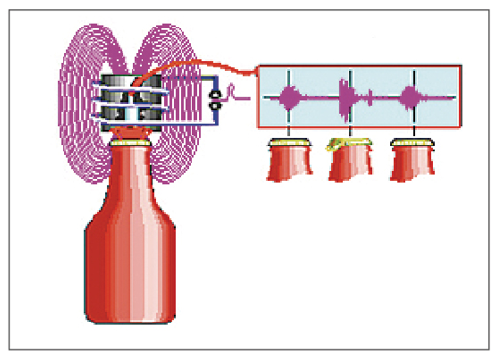

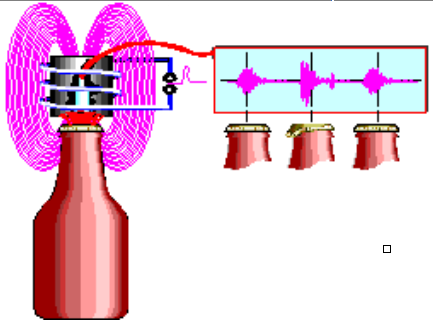

Compatible Container Types: Applicable to cans, three-piece cans, glass bottles, metal caps, and other flat magnetic closures (see illustration below).

II. Detection Principle

The system applies electromagnetic pulse (EMP) technology, which generates an instantaneous, directional pulse toward the surface of the cap. The resulting magnetic field excites the cap, causing it to vibrate and emit an echo. This echo is captured by a sound sensor embedded in the probe and transmitted to the analysis unit. Because products with leaks exhibit a different internal-to-external pressure profile compared to properly sealed products, the echo signals vary accordingly. By distinguishing these acoustic differences, the system can reliably determine whether the product’s seal is intact.

Acoustic wave detection principle diagram

II. Detection Principle

The system employs surface scanning technology to continuously monitor the top of each glass bottle cap. In cases of poor sealing or abnormal internal pressure, sudden changes occur on the cap surface. These variations are used as indicators to determine whether the cap’s sealing integrity (or internal pressure) meets quality standards.

III. Equipment Features

Non-contact inspection ensures high speed and accuracy without affecting the product.

Adaptive performance automatically adjusts to changes in production line speed, enabling real-time dynamic detection.

Sealed design of the main unit provides airtight, fog-resistant, and waterproof protection for excellent environmental adaptability.

Hardware-based circuitry combined with an embedded operating system delivers reliable, long-term stability.

Dual alarm system integrates both audible and visual alerts, while defective containers are automatically removed.

User-friendly interface with Chinese language support, LED-backlit LCD, and clear interactive display.

High-capacity storage supports up to 10 product profiles, streamlining automated operation and product switching.

Excellent cost-performance ratio, with all critical components sourced from internationally recognized brands for dependable quality.

Durable construction using 304 stainless steel frame and supports, with industrial protection rated up to IP65.

Advanced acoustic technology, incorporating sonar detection and sound analysis methods developed by the Institute of Oceanography.

Detection accuracy:

serial number

| Detection Items | Testing Conditions and Accuracy | Rejection rate

| False kick rate

|

1 | Leakage test | -- | -- | < 0.03% |

1.1 | No lid | No screw cap | >99.99% | |

1.2 | No Gasket Detection | Missing rubber gasket | >99.9% | |

1.3 | Double Gasket Detection | Double rubber gasket | >99.93% | |

1.4 | Air Leak Detection | Product leakage | >99.99% | |

1.5 | Expansion cans and other special-shaped cans | >99.9% |

Note: Rapid temperature changes will affect the detection results and cause false rejections.

V. Installation Requirements

This equipment is installed on a horizontal, single-row conveyor chain. It consists of two components: detection and rejection. The conveyor chain must be at least 1.5 meters long, preferably longer. Ensure the chain plate remains stable during conveying, and the equipment must be installed after the cooler for inspection. (Important)

Installation location

1. The lid material must be magnetic and must be from the same batch during production. Mixing lids from multiple batches may reduce detection effectiveness.

2. Power supply: 220V, 50Hz AC, with a total power draw of less than 120W. If you are using a different voltage standard in a foreign country, please inform us in advance.

3. External compressed air is required for rejection, with a minimum pressure of 4 bar and a maximum pressure of 12 bar.