Empty Can Inspection

1.With an image inspection system developed independently,

2.the maximum speed can reach 1000 cans / min.

3.Reliable detection and stable operation for long time Easy to install and easy to operate

I. Equipment Parameters and Site Description

1. Project Overview

1.1 Project Name: Empty Can Detection System

1.2 Description: This system applies advanced machine vision technology to achieve fully automated, non-contact, online inspection of empty cans. It identifies defects such as mouth deformation, dents, body contamination, internal foreign matter, and under-pressurized cans.

1.3 Rated Capacity: 1000 cans/minute

1.4 Container Type: Two-piece cans

1.5 Product Volume: 100 mL – 600 mL

2. Environmental Conditions

Operating Altitude: 5–3000 m above sea level

Operating Temperature: 5°C – 40°C

Relative Humidity: 50%–65% RH

Factory Requirements: Floor flatness and load-bearing capacity must comply with national standards to ensure stable operation.

Storage Conditions: Equipment and components must be stored in compliance with national standards. During storage, proper lubrication and maintenance are required to prevent surface damage or deformation that could affect installation, commissioning, or operation.

3. Operating Conditions

Noise Level: ≤85 dB (actual values may vary depending on container type, machine power, and site acoustics).

Power Requirements:

Voltage: 220V, 50Hz, single-phase (special voltage requirements must be specified in advance; variations may affect equipment specifications, delivery, and pricing).

Total Power Consumption: Approx. 1.0 kW

Control Voltage: 24 VDC

4. Equipment Description

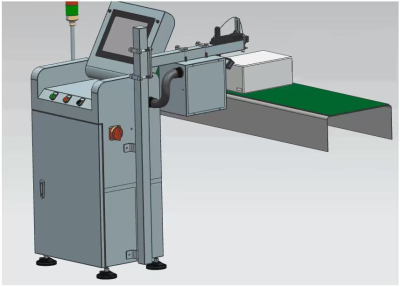

4.1 General Information

Equipment Name: Empty Can Detector

Model: MT-YLG-KG-C1-01

Quantity: 1 set

Inspection Speed: 1000 cans/minute

Applicable Container: Two-piece cans

Production Line Compatibility: Lines with a speed of ≤1000 cans/minute

Installation Location: On the single-lane conveyor, positioned before the filling machine

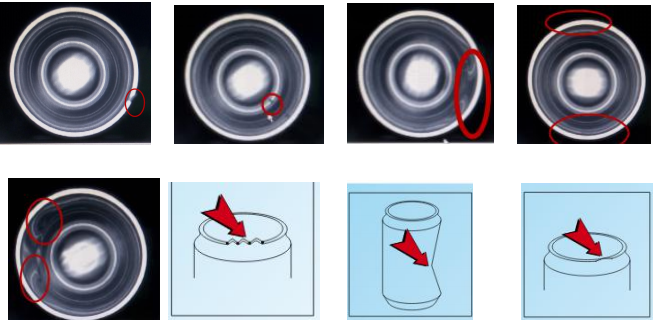

Function: Uses high-resolution cameras to inspect empty cans for defects including mouth deformation, tearing, V-notches, flaps, dents, foreign objects on the body, and internal contamination. Defective cans are automatically rejected online.

4.2 System Principle, Workflow, and Installation

Workflow:

A positioning sensor detects each incoming can, records its ID, and logs the encoder value via the control unit.

The camera captures an image of the can. The image processor analyzes the data and forwards the results to the HMI for live monitoring and to the control unit for rejection decisions.

If a defect is identified, the PLC activates the rejector to remove the corresponding can.

Installation Requirement:

A 2 m straight conveyor section must be provided.

Cans must not be squeezed together; a gap of at least 2 cm between cans is essential.

This requirement is critical to ensure reliable inspection accuracy.

4.3 Empty Can Inspection Module

4.3.1 Inspection Scope and Accuracy:

The module is designed to detect multiple defect types with high precision, including mouth defects, dents, body contamination, and foreign objects inside cans. Detection accuracy ensures defective cans are reliably identified while minimizing false rejections.

Detection position

| Defect type

| Accuracy

| Illustration

| Rejection rate

| False rejection rate

|

Can mouth

|

Can mouth curling notch

|

1 mm X 1 mm |

≥99.9% |

≤0.05% | |

Deformation of the can mouth flange

| Upward or downward protrusion height ≥ 2mm or horizontal length ≥ 4mm

|

≥99.9% | |||

Depression at the mouth of the tank

| 5% overall

| ≥99.9% | |||

Can mouth ovality

| ≥1cm | ≥99.9% | |||

Dirt on the can edge

| 2 mm x 2 mm, thickness ≥ 1 cm

| ≥99.9% | |||

Tank inner wall

| Dirt in the middle of the inner wall

| 3 mm x 3 mm, thickness ≥ 1 mm

| ≥99.9% | ||

bottom of jar

| Foreign matter in the middle of the tank bottom

| 3 mm x 3 mm, thickness ≥ 1 mm

| ≥99.9% | ||

Foreign matter (opaque) inside the tank bottom ring

|

3 mm x 3 mm, thickness ≥ 1 mm

|

≥99.9% | |||

Hole in the middle of the tank bottom

| 3 mm X 3 mm | ≥99.9% | |||

Can body

| Can body deformation

| Deformation: 4mm Deformation: ±1mm

| ≥99.9% | ||

Description (Please read carefully)

| This solution adopts a single-station single-lens inspection method, the main purpose of which is to control the can mouth (strict precision), large flat cans and large foreign objects. Since the subsequent processes include hot water washing and filling with nitrogen, small foreign objects can be washed away by hot water. Therefore, the detection accuracy of small foreign objects and small deformation of the can wall will be lower.

| ||||