Cap Inspection For Tetra Pak Bags

1.Non contact online Inspection, no damage to the product.

2.Fast nspection speed, up to 24000 packages per hour at the fastest.

3.Equipped with Al algorithms for more reliable Inspection

4.Muli spectral lnspection with stronger compatibility

I. Equipment Overview

1. Purpose

This system is designed for the online inspection of cap quality and inkjet printing quality on the Diamond Packaging production line. Any products with defective caps or poor-quality inkjet codes are automatically identified and rejected.

2. Key Features

Non-contact, inline inspection – no physical impact or damage to products.

High-speed capability – supports inspection of up to 24,000 bags per hour.

User-friendly HMI – flexible interface with multi-level access control.

Industrial-grade cooling system – ensures stable operation and prevents faults during extended summer use.

Customizable functions – tailored to meet specific customer production needs.

Defect traceability – automatically stores images of defective caps; storage period can be customized.

Remote support – 24/7 remote monitoring and equipment control service.

Smart rejection control – automatic line stop after a preset number of consecutive defective rejections.

Comprehensive 360° cap inspection – minimizes false rejects caused by packaging friction or handling.

360° inkjet code inspection – reduces false rejects caused by scraping or grabbing of the package surface.

Zero-delay cap inspection – unaffected by cap material, color variation, or packaging material interference.

II. Inspection Capabilities

Cap presence detection

Cap position deviation detection

Cap rotation detection

Inkjet code presence verification

Missing code detection

Code integrity verification (elongation, shortening, position deviation, duplicate printing)

3. Installation location

Installation Location:

On-site installation location: 1.5-2 meters straight behind the capping machine.

4. Detection principle

Two Gigabit digital cameras are used to take photos from top to bottom, respectively capturing images of paper bags, bottle caps and inkjet codes. The captured images are digitally analyzed, and paper bags with unqualified bottle caps or inkjet codes are automatically removed online.

When a diamond package passes a positioning sensor, its arrival is detected and the control unit records the package's identification number and the current encoder signal. The positioning sensor triggers a digital camera to capture images of the package's cap and inkjet print, transmitting them via the network to an image processor. The image processor processes and analyzes the received images, transmitting the results to the human-machine interface for dynamic display and to the control unit. Upon receiving a signal indicating a failed cap or inkjet print, the control unit notifies the rejector to remove the cap or inkjet print-rejected package online.

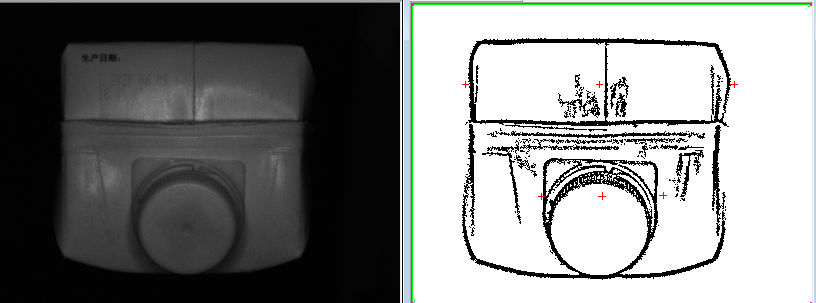

Bottle cap image processing effect, the left is the original image, the right is the processed image

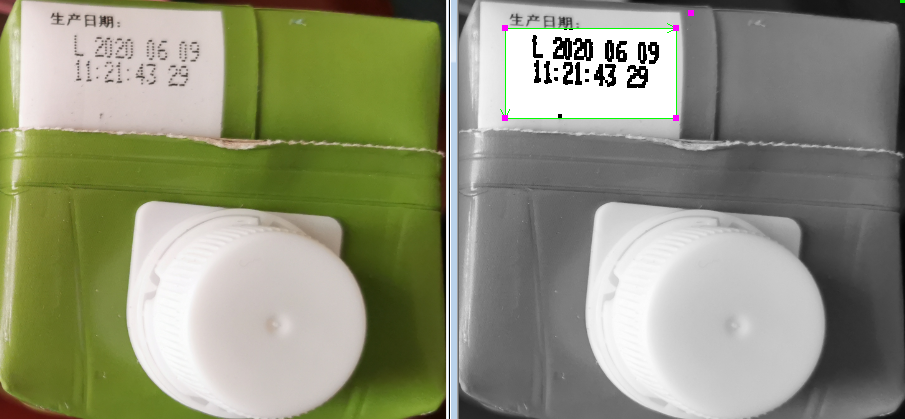

Diamond bag processing effect (injection code interpretation: L: factory code, 29: anti-counterfeiting code, others are current product production time)

V. Equipment Configuration Details and Inspection Accuracy

(I) Detailed Equipment Description

A. Technical Parameters

Equipment Name: Diamond Pack Cap Inkjet Printer

Model: MT-LL-PG-PM-C2

Applicable Production Speed: 24,000 packs/hour

Inspection Area: Cap inspection, inkjet printing inspection

Rejection Method: Automatically rejects diamond packs with defective caps or inkjet printing detected by the inspection unit

Safety Protection Rating: IP65

B. Main Applications:

Widely used in diamond pack beverage production lines, inspecting and automatically rejecting all types of diamond pack caps and inkjet printing.

C. Technical Features:

1. Reduces personnel and production costs

2. Improves production efficiency and product quality

3. Bottle cap inspection machine test results meet manufacturer's relevant technical standards.

D. Detection accuracy:

Inspection Items | Inspection Contents | Diagram | Rejection Rate

| False detection rate

| |

Bottle Cap Inspection

Inkjet Printing Inspection | Absent cap | ≥99.99% | <= 0.01% | ||

Cap misalignment | The bottle cap is offset from the center of the aluminum foil wrap (5mm above, below, and to the left). | ≥99.99% | <= 0.01% | ||

Cap rotation (vertical distance difference between top and bottom cap ≥ 5mm) | ≥99.99% | <= 0.03% | |||

Inspection Items | No inkjet print | ≥99.99% | <= 0.01% | ||

Overall inkjet print missing > 50% | ≥99.99% | <= 0.01% | |||

Overall inkjet print missing > 30% | ≥99.96% | <= 0.01% | |||

Deformed inkjet print (stretched, squeezed), duplicated, or reversed packaging | ≥99.98% | <= 0.01% | |||

Note: The above detection accuracy is the standard accuracy. The specific accuracy needs to be adjusted according to the specific situation of the product bottle cap. The final accuracy is subject to the contract agreement. The final interpretation right of the detection accuracy and rejection rate belongs to Maotong Company.

| |||||

Note: The rejection rate of the test item "no bottle cap" described in the table means that out of 10,000 packages of unqualified products without bottle caps tested by the equipment, there may be 1 package that is not rejected. This is only theoretical experimental data, and the same applies to other test items.