Tetra Pak Detection Machine

1.Self developed testing software, processing speed is fast,the fastest up to 36000 packets / hour

2.Replace labor, cost saving, high cost performance

3.Unique lighting design,not affected by th e paper package shading

I. Equipment Introduction

1. Purpose

This system is designed for online inspection of inkjet printing quality and straw integrity on paper-packaged products along the Linying Jiayin production line. It automatically identifies and rejects defective products, ensuring packaging quality and production efficiency.

2. Key Features

Non-contact, real-time inspection that causes no damage to the product.

High detection efficiency, supporting speeds of up to 24,000 packages per hour.

User-friendly human-machine interface (HMI) with multi-level access control.

Accurate rejection control: An encoder mounted on the conveyor’s synchronous motor ensures that even during line stoppages or speed fluctuations, rejection accuracy remains unaffected.

Equipped with industrial-grade cooling and air conditioning systems to prevent malfunctions or false alarms during extended summer operations.

Functionality can be tailored to customer-specific production conditions.

Daily automatic photo storage of defective products, with customizable retention periods.

Continuous rejection capability and automatic line shutdown when defect thresholds are reached.

Remote monitoring and control, available 24/7.

Comprehensive 360° inkjet code inspection, ensuring no blind spots.

Zero-delay detection to eliminate false rejections caused by packaging scratches, jams, or manual handling.

II. Detection Functions

Code presence verification (missing code, inverted package).

Blurred code detection (illegible, distorted, or human-eye unreadable codes).

Incorrect code identification.

Detection of missing characters.

Character recognition and decoding of code information.

Position deviation detection (outside preset range).

Duplicate code detection.

Straw presence verification (missing straw).

III. Installation Location

The equipment should be installed on the conveyor line 0.5–1.0 meters downstream of the tube applicator, allowing simultaneous inspection of both inkjet codes and straws.

IV. Detection Principle

A Gigabit Ethernet digital camera captures top-down images of each package.

The captured images are transmitted to the image processor for digital analysis.

If defects are detected, the control unit signals the rejector to remove the faulty package from the line.

Process Flow:

As a package passes the positioning sensor, the sensor records its arrival.

The control unit logs the package ID and encoder signal.

The positioning sensor activates the camera to capture the package’s inkjet code and straw image.

The image processor analyzes the image and sends results to both the HMI (for real-time monitoring) and the control unit.

If the package is identified as defective, the rejector is triggered to remove it.

Algorithm Principle:

The inspection relies on deep learning algorithms, significantly reducing manual intervention. During model changeovers, only around 300 product images are required to train the system. Our company builds and updates the data model, ensuring that once all product variations are covered, the system achieves truly foolproof inspection capability.

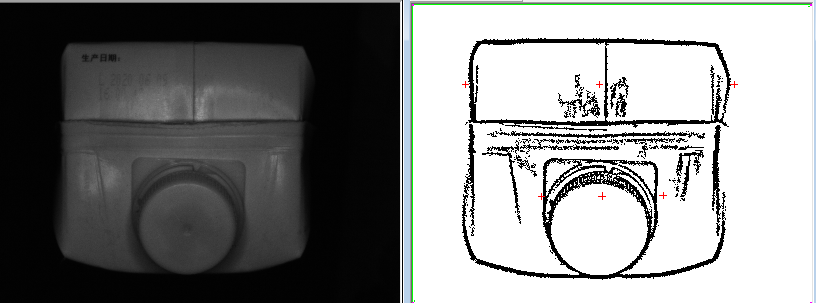

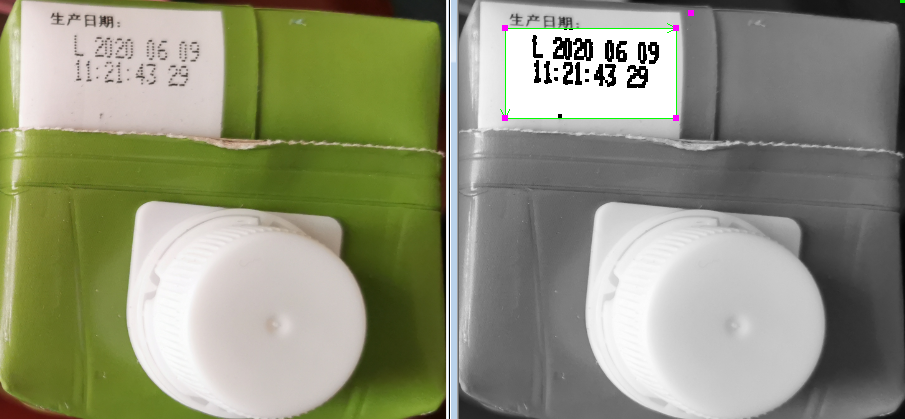

Bottle cap image processing effect, the left is the original image, the right is the processed image

Bottle cap image processing effect, the left is the original image, the right is the processed image

V. Equipment Configuration Details and Inspection Accuracy

(I) Detailed Equipment Description

A. Technical Parameters

Equipment Name: Inkjet Printer Inspection Machine

Model Name: MT-LL-PM-C1-01X

Applicable Production Speed (Max): 24,000 bags/hour

Inspection Area: Inkjet Printer Inspection, Straw Inspection

Rejection Method: Accurately rejects defective bags detected by the inspection unit

Safety Protection Rating: IP65

B. Main Applications:

Widely used in paper-packaged beverage production lines, inspecting and automatically rejecting inkjet prints on various paper packages.

C. Technical Features:

1. Reduces personnel requirements and reduces production costs.

2. Improves production efficiency and product quality.

3. The inspection results of the inkjet printer meet the manufacturer's relevant technical standards.

D. Detection accuracy:

Serial Number

| Inspection Items | Testing Conditions and Accuracy | Rejection rate

| False kick rate

|

1 | Inkjet Printing Inspection | -- | -- | < = 0.03% |

1.1 | No inkjet printing (missing code, reversed package) | -- | >99.99% | |

1.2 | Missing inkjet printing Blurred inkjet printing | Overall code missing >50% | ≥99.99% | |

Overall code missing >30% | ≥99.96% | |||

1.3 | Incorrect inkjet printing | Code characters unreadable to the human eye | >99.93% | |

1.4 | Position offset | Incorrect production date, incorrect factory code, incorrect security code, deformation (elongation or shortening) | >99.99% | |

1.5 | Duplicate code | Exceeding the expansion zone | >99.99% | |

1.6 | Straw inspection | Multiple codes printed within the code area | >99.99% | |

2 | Inspection Items | No straw | >99.99% | <= 0.01% |

Note: The rejection rate for the "No Coding" test item in the table indicates that for every 10,000 uncoded packages tested by the equipment, one package might not be rejected. This is theoretical experimental data only, and the same applies to other test items. The above test items are tested in real time for each paper package, not just during shift changes to determine coding errors.