Company News

Food bags whiz by on the production line at a rate of 300 per minute, while an advanced vision-based inspection system captures every printing defect with 100% accuracy, minimizing food safety risks.On high-speed food production lines, the production date, expiration date, and batch number on each

2025/12/11 07:49

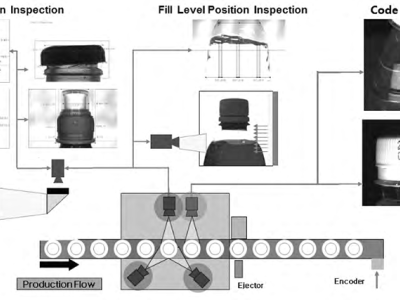

On modern filling production lines in industries such as beverages, daily chemicals, and pharmaceuticals, every bottle must undergo a crucial "visual inspection"—liquid level visual inspection—before capping. This technology acts like a tireless "smart eye" on the production line, accurately and

2025/12/10 13:47

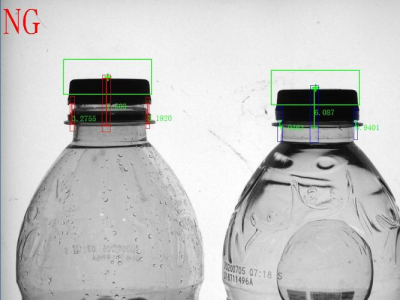

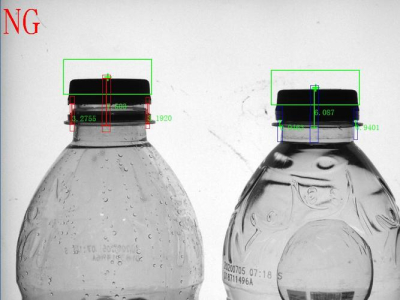

1. Importance and Background of Full-Bottle Inspection for PET BottlesPET bottles are widely used packaging containers in the beverage, food, and pharmaceutical industries. On high-speed filling production lines, defects such as excessively high or low liquid levels, and substandard cap sealing may

2025/12/09 16:46

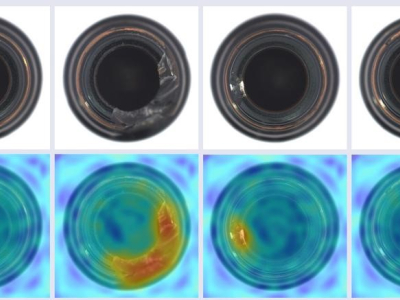

In the food, pharmaceutical, and cosmetic industries, glass bottles are widely used as packaging materials due to their high chemical stability and excellent barrier properties. However, during production or filling, foreign objects such as metal fragments, glass shards, hair, or fibers may become

2025/12/08 10:58

Foreign object detection in bottled beverages is a crucial step in food safety production. Currently, mainstream detection technologies have achieved a high degree of automation, efficiently identifying and rejecting substandard products. Below are some core detection methods.Image Sequence-Based

2025/12/05 10:02

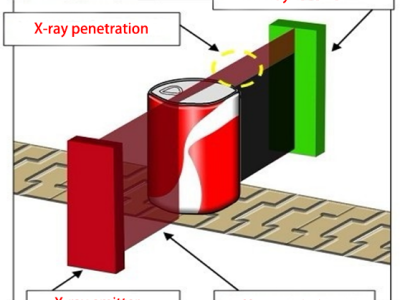

Detecting leaks in aluminum-bottom tinplate cans requires selecting the appropriate method based on the production process and precision requirements. Below is a summary of common detection methods, their applicable scenarios, and some practical operational points.Overview of Common Leak Detection

2025/12/02 12:00

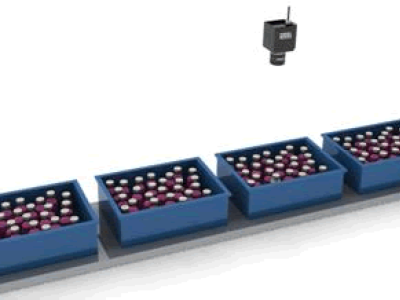

On production lines where thousands of cans flow at a rate of thousands per minute, an invisible "eye" silently safeguards the quality and dignity of every can of beverage.In the food and beverage industry, precise control of can levels not only affects company costs but also directly impacts brand

2025/11/19 10:58

The integrity of the seal on medicine bottles is crucial for ensuring the sterility and effectiveness of medicines. The table below summarizes the main leak detection methods, helping you quickly understand their characteristics and applicable scenarios.Detection MethodCore PrincipleApplicable

2025/11/14 10:30

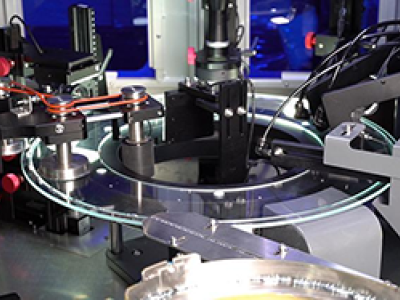

#appearance visual inspectionIn the grand landscape of smart manufacturing, appearance visual inspection equipment is undergoing a profound intelligent transformation. Entering 2025, with increasingly stringent quality control across industries and the continued advancement of Industry 4.0 and

2025/11/11 10:47

Sealing detecting of beverage bottles is a crucial step in ensuring product quality and safety. The table below summarizes the main testing methods and their characteristics to help you quickly understand them:Detecting Method Method ClassificationCore PrincipleApplicable Packaging/

2025/11/10 11:13

Project OverviewWater, as an essential energy source for human life, has always played a crucial role in people's lives. With the development of social production and changing consumer demand, a variety of beverages made from water have emerged. These beverages have given water a variety of new

2025/10/11 10:02

Maotong (usually referring to Jinan Maotong Inspection Equipment Co., Ltd.)'s air leakage detection equipment is widely used in the food and beverage packaging industry. It primarily uses squeeze detection technology and online automated testing to ensure packaging sealing.The following table

2025/10/01 18:03