How to detect the seal of a beverage bottle

Sealing detecting of beverage bottles is a crucial step in ensuring product quality and safety. The table below summarizes the main testing methods and their characteristics to help you quickly understand them:

| Detecting Method | Method Classification | Core Principle | Applicable Packaging/Scenario | Reference Standard |

| Vacuum Decay Method (Negative Pressure Method) | Offline/Sampling | Immerse the sample in water, create a pressure difference by evacuating the vacuum chamber, and observe whether continuous bubbles are generated | Plastic bottles (such as PET bottles), packaging bags, tubing, cans, etc.; suitable for the food, pharmaceutical, and other industries | GB/T 15171 |

| Positive Pressure Method (Pressure Decay Method) | Offline/Sampling | Inject a certain pressure of gas into the packaging, and determine the sealing performance by monitoring pressure changes or observing bubbles in the water | Carbonated beverage bottles (withstanding internal pressure), bottle cap sealing strength, tamper-evident caps, aerosol valves, etc | QB/T 1868 (Carbonated Beverage Bottles), GB17876 |

| High Voltage Discharge Method | Offline/Sampling | Uses electrodes to scan the container, and determines the sealing performance by detecting changes in current caused by leakage; high sensitivity. Aseptic pharmaceutical packaging such as plastic infusion bottles, BFS (Body-Free Solution), and ampoules; especially suitable for high-viscosity liquid preparations | Guidelines for the sealing of pharmaceutical packaging systems (e.g., YY/T 9628) | |

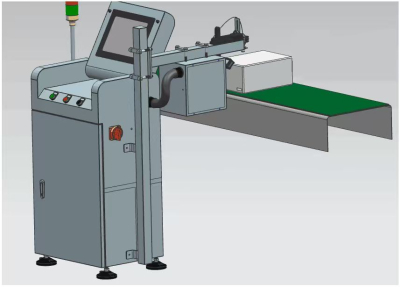

| Online Vision/Height Detection | Online/High-Speed | For nitrogen-filled packaging, sensors or vision systems are used to measure the height of the cap protrusion; insufficient height indicates nitrogen leakage | On high-speed production lines, cans, nitrogen-filled beverage bottles, etc., can achieve 100% online detection before sterilization | (Patent method CN117399299A) |

Understanding the Core Principles of Detection Methods:

Different detection methods are based on different physical principles and are suitable for different scenarios:

Negative Pressure Method and Positive Pressure Method: Both methods essentially work by creating a pressure difference between the inside and outside of the packaging. The negative pressure method (such as the vacuum decay method) "depressurizes" the outside of the packaging, and the relatively higher internal pressure drives gas to escape from the leak point. The positive pressure method "pressurizes" the inside of the packaging; excessive internal pressure will leak from the leak point or cause the packaging to deform and rupture. Negative pressure testing is widely used and intuitive; positive pressure testing better simulates the actual pressure conditions of products like carbonated beverages.

Height detection method: This is a very clever indirect detection method. Some beverages (such as beer) are filled with a small amount of liquid nitrogen after bottling. The nitrogen vaporizes inside the bottle, creating pressure and causing the cap to bulge slightly. Bottles with poor sealing will leak, resulting in insufficient cap bulging. By measuring the height or contour of the cap using high-precision sensors or vision systems, the sealing performance can be quickly determined. This method is very suitable for high-speed production lines.

Choosing the appropriate testing solution: When selecting a sealing performance testing method, the following factors need to be considered:

Product type: Carbonated beverages, due to their carbon dioxide content and internal pressure, typically require positive pressure testing to assess their internal pressure resistance and sealing performance. Ordinary non-carbonated beverages and water can be tested using negative pressure testing (vacuum decay method). For pharmaceuticals with extremely high sterility requirements (especially injectables), highly sensitive methods (such as high-voltage discharge methods) are needed to detect minute leaks and ensure a sterile barrier.

Production and Efficiency Requirements: If 100% inspection of every product is required on a high-speed production line, online visual/height inspection is ideal. For sampling inspection or laboratory quality analysis, more comprehensive and accurate offline equipment, such as vacuum decay or positive pressure sealing testers, can be selected.

Detection Sensitivity and Leakage Standards: Different products have different tolerances for leaks. It is essential to clearly define the minimum leak diameter to be detected and ensure that the sensitivity of the selected method meets the requirements.

Operational Points and Common Misconceptions:

In actual operation, please note the following:

Follow Standards: Strictly follow relevant national and industry standards (such as GB/T 15171, QB/T 1868) or company internal procedures, and standardize parameter settings (such as vacuum degree, pressure value, and holding time).

Avoid Misconceptions: Never rely on unscientific, rudimentary methods, such as manually squeezing the packaging to judge its tightness, as this is extremely inaccurate and unreliable.

Equipment Maintenance and Calibration: Ensure that the testing equipment is calibrated and maintained regularly to guarantee the accuracy and reliability of test results.

Key Takeaways Summary: Bottle seal testing is crucial for ensuring quality. When choosing a method, the core considerations are product characteristics (e.g., whether it's a carbonated beverage), production mode (sampling or full inspection), and the necessary testing sensitivity. Standardized procedures and avoiding reliance on unscientific, makeshift methods are fundamental to ensuring valid results.

Hopefully, this information helps you better understand bottle seal testing. If you could share which type of beverage (e.g., mineral water, carbonated drinks, juice) or production scenario you're specifically interested in (e.g., laboratory research or production line quality control), I can provide more targeted analysis.