How to Detect Foreign Objects in Beverage Bottles?

Foreign object detection in bottled beverages is a crucial step in food safety production. Currently, mainstream detection technologies have achieved a high degree of automation, efficiently identifying and rejecting substandard products. Below are some core detection methods.

Image Sequence-Based Analysis Methods: These methods analyze multiple images taken consecutively while the bottle is in motion, utilizing the principle that "foreign objects move relative to the bottle."

Dual-Camera Differential and Sparse Representation: One method involves placing cameras at two different locations on the production line to capture images of the same inverted bottle of liquid at different times. Complex image processing algorithms (such as effective detection area calibration and image sparsity representation) are used to identify abnormal areas in both images. Finally, by comparison, connected regions that overlap in the two images (usually inherent scratches or defects on the bottle) are removed, thus accurately determining the remaining foreign object areas.

Oscillating Follow-up Detection: Another newer technique involves having the bottle oscillate back and forth on an oscillating mechanism. The key is that the bottle, camera, and light source are all fixed to the oscillating mechanism, maintaining a completely stationary relative position during the oscillation. In this way, the liquid inside the bottle sloshes, causing foreign objects to move, while the camera captures a clear and stable sequence of images. Using image difference analysis, moving foreign objects can be easily detected. A significant advantage of this method is that the oscillating mechanism can stop briefly at certain points, at which point the liquid surface gradually stabilizes, but floating or suspended foreign objects will still move slowly, thus being effectively detected, overcoming the difficulty of detecting floating foreign objects in traditional methods.

Optical Property-Based Analysis Methods

These methods focus on analyzing the different reactions of foreign objects and the bottle itself to light.

Multispectral Illumination and Analysis: An advanced technology using an illumination unit with a planar luminescent surface, but its essence lies in the fact that light is emitted from different positions on the luminescent surface, with different emission directions and different wavelength ranges. When light passes through the container, defects on the container surface (such as scratches) and foreign objects inside (such as impurities) will have different effects on the light. Defects usually cause light to refract at specific angles, while foreign objects mostly cause light absorption or scattering. After the camera captures an image, the image processing system separates and evaluates information from different wavelength channels, effectively distinguishing defects on the bottle body from internal foreign objects.

Rotational Positioning Analysis (for highly viscous liquids): For highly viscous products such as gels, the traditional rotation-stop method fails due to the poor fluidity of the liquid. One solution is to rotate the transparent container and continuously acquire multiple frames of images. The location of the target defect is extracted from adjacent frames. If the defect is a scratch fixed on the outside of the bottle, its position in the next frame can be accurately predicted based on the bottle's rotation angle and radius, with the predicted position closely matching the actual position. However, if the defect is an internal foreign object, the predicted and actual positions will deviate significantly due to its different trajectory from the bottle body. The two locations can be effectively distinguished by calculating the area overlap between the two positions.

Other Detection Technologies

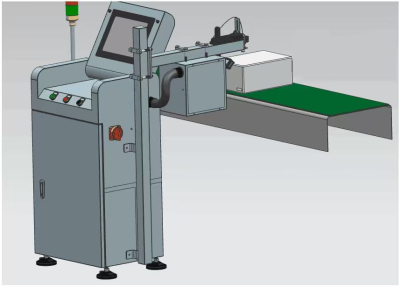

X-ray Detection Systems: For example, X-ray detection machine utilizes the principle of X-ray transmission to detect various foreign objects such as metal, glass, gravel, and bone. This technology can not only detect foreign objects but also simultaneously check the integrity of the packaging and whether the contents are full, making it ideal for high-speed production lines.

Spin-Stop Method: This is a more traditional but classic method. The bottle is spun at high speed and then stopped abruptly. The liquid inside continues to move due to inertia, while the defect on the bottle remains stationary. By capturing and analyzing images of the moving target in the liquid after the sudden stop, foreign objects can be identified. Companies like Seidonard and Bosch in Germany have mature equipment based on this principle.

How to Choose a Detection Solution: Choosing the right method requires considering several factors:

Liquid Properties: Aqueous liquids are the most widely applicable. For highly viscous liquids, liquids containing bubbles, or opaque liquids, the effectiveness of different technologies needs to be evaluated; X-ray technology is generally more adaptable.

Production Speed: High-speed production lines (e.g., tens of thousands of bottles per hour) require systems with high processing speeds.

Container Characteristics: The bottle's material (glass, PET plastic), color (transparent, translucent, dark), shape (regular, irregular), and whether recycled bottles are used (many scratches) all affect the detection results and solution selection.

Foreign Object Types: Clearly define the main types of foreign objects to be detected (e.g., metal, glass, hair, insect fragments, etc.). Different technologies have varying sensitivities to different types of foreign objects.

Cost Budget: This includes the initial investment in equipment, subsequent maintenance costs, and operator training costs.