Can Level Detection Technology: The Guardian of Quality in Modern Bottling Production Lines

On production lines where thousands of cans flow at a rate of thousands per minute, an invisible "eye" silently safeguards the quality and dignity of every can of beverage.

In the food and beverage industry, precise control of can levels not only affects company costs but also directly impacts brand reputation and consumer experience. Excessive levels can lead to poor sealing or overflow, while insufficient levels can cause consumer dissatisfaction.

Traditional sampling inspection methods are inefficient, while modern X-ray level detection technology, with its high precision and efficiency, has become a key technology for ensuring bottling quality.

1. Technical Principles Revealed

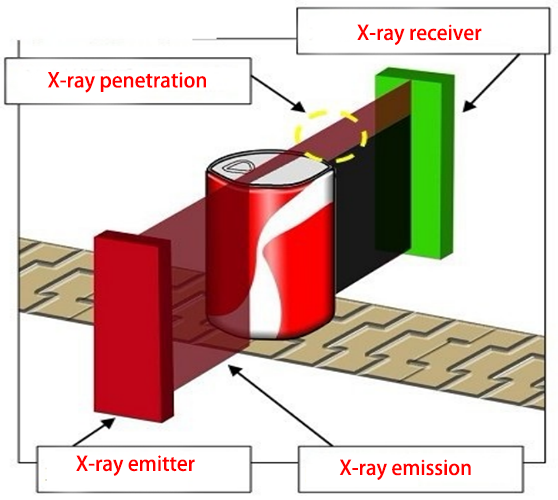

The core of can level detection technology lies in using physical principles to achieve non-contact measurement. Mainstream X-ray detection technology uses a source to emit low-energy photon beams, which penetrate the container and are captured by a receiver.

When the rays pass through the can, different liquid levels absorb the rays to varying degrees, creating different projection signals at the receiver. The system uses this information to accurately determine the liquid level.

Besides X-ray technology, various other detection methods coexist in the market. Optical inspection analyzes the liquid level position using a vision system; ultrasonic inspection calculates distance using sound wave echo time; and gravity sensing technology indirectly determines the liquid level by weighing. Each technology has its advantages and disadvantages, adapting to different production environments and accuracy requirements.

Non-contact measurement is a common advantage of these technologies, avoiding the contamination problems that can occur with traditional contact inspections and perfectly complying with food hygiene and safety standards (such as HACCP and FDA). At the same time, they do not damage the can or label, ensuring the integrity of the product's appearance.

2. Technical Advantages Analysis The core competitiveness of can level detection equipment lies first and foremost in its remarkable detection accuracy. Modern equipment can achieve an accuracy within ±0.5mm, with some high-end models even reaching ±0.4mm.

This precise control avoids a series of problems caused by insufficient or excessive filling, directly reducing the scrap rate due to substandard liquid levels and saving companies significant raw material costs.

In terms of efficiency, modern level detection equipment can adapt to the demands of high-speed production lines. The MT1500 model boasts a testing speed of up to 1500 cans per minute (≤90000 BPH), sufficient to match the production pace of the most advanced filling lines. This high-speed online testing capability enables real-time feedback synchronized with the production line, ensuring it does not become a bottleneck in the production process.

The equipment's flexibility is equally impressive. Through modular design or parameter adjustments, the same machine can adapt to packaging containers of different capacities (from 250ml to 1000ml) and shapes. Whether it's two-piece cans, three-piece cans, PET bottles, or glass bottles, the testing system can handle them with ease.

Data traceability and quality management are another major highlight of modern testing equipment. The system can monitor abnormal liquid levels in real time and immediately trigger alarms or shutdowns to prevent batch defects. Simultaneously, testing data is fully recorded, supporting production batch traceability and quality analysis, providing data support for process optimization.

3. Equipment Performance Parameters The technical specifications of can level testing equipment vary depending on the model to meet different production needs. Taking the MT1500 model as an example, its testing speed can reach 1500 cans per minute, suitable for high-speed production lines. The MT2000 model further increases this figure to 2000 cans/minute (≤120000 BPH).

Regarding environmental adaptability, the typical operating temperature range is 0℃-50℃, humidity range is 0-90% (non-condensing), power requirements are AC220V/110V±10%, and power consumption is typically ≤150W.

The equipment is primarily constructed from 304 stainless steel (SUS 304) and anodized hard aluminum, ensuring corrosion resistance in humid production environments. With an IP65 protection rating, it can withstand high-pressure water washing, fully meeting the cleanliness requirements of food and beverage production lines.

In terms of installation location, the equipment is typically installed on a pressureless, single-channel straight conveyor after the filling and capping of the cans. This standardized installation requirement reduces the difficulty of equipment integration and facilitates rapid deployment into existing production lines.

4. Wide Range of Application Scenarios Can level detection technology plays a crucial role in multiple scenarios. The most common application is in the quality control stage of filling lines, where real-time detection is performed immediately after filling to accurately intercept defective products.

On the production line, the cans pass through an X-ray emission channel. Utilizing the penetrating principle of X-rays, products at different liquid levels form different projections at the X-ray receiver. The system determines whether the product's liquid level is acceptable based on preset standard parameters and automatically rejects defective products.

For upgrading existing production lines, liquid level detection equipment can effectively replace traditional manual sampling, improving the production line's intelligence level. One company successfully saved two manual positions by introducing an automated detection system, while also avoiding the possibility of human error.

In the new product development stage, the rapid adaptability of the detection equipment significantly shortens the new product launch cycle. When a company launches a new packaging design, the detection equipment can quickly adapt to the new can type by adjusting parameters or replacing modules, without requiring large-scale equipment investment.

5. Value to the Production Line The can liquid level detection equipment creates multi-dimensional value for manufacturing companies. In terms of cost control, by accurately controlling the filling volume, the equipment significantly reduces the scrap rate caused by substandard liquid levels, saving raw material costs. Non-contact sensors offer long lifespans and simple daily maintenance, reducing long-term operating costs.

Quality improvement is another core value proposition. Inspection equipment ensures uniform liquid levels in every can, preventing consumer complaints due to insufficient liquid levels and maintaining brand image. This consistency guarantee is crucial for brand reputation, especially for high-end beverage brands, where level uniformity is a fundamental quality commitment.

With the development of the Industrial Internet of Things (IIoT), modern liquid level detection equipment can seamlessly integrate with PLCs or IIoT systems, achieving fully automated control and reducing manual intervention. This automation integration capability is a fundamental element in building smart factories, supporting enterprise digital transformation.

In terms of environmental protection and safety, the inspection equipment reduces raw material waste caused by overfilling, aligning with green production principles. Furthermore, while X-ray inspection technology uses nuclear technology, it produces no waste and is safe and reliable in terms of radiation protection, ensuring safety for both operators and the environment.

In the future, with the integration of artificial intelligence and machine learning technologies, liquid level detection equipment will not only be limited to judging "qualified" and "unqualified," but will also be able to predict filling system deviations through big data analysis, providing early warnings before problems occur, thus shifting from quality control to quality prevention.

In the wave of smart manufacturing, liquid level detection equipment has become a core node in digital factories. The massive amounts of data they generate are interconnected with other parts of the production line, forming a complete quality information loop and continuously optimizing production processes.

Behind every can of beverage, there is such a silent quality guardian, using technology to ensure product consistency and reliability, allowing consumers to have the perfect experience they deserve every time they open a can of drink.