Visual Inspection Technology: An Intelligent Guardian of Food and Beverage Quality and Safety

On high-speed modern production lines, bottles and bags of beverages undergo scrutiny sharper than the human eye—this is the quality revolution brought about by machine vision inspection technology.

On today's food and beverage production lines, visual inspection systems can inspect at speeds exceeding 500 bottles per minute, achieving millimeter-level accuracy, far exceeding the limits of the human eye. These systems not only identify minute defects but also guarantee over 99.9% accuracy, becoming the "intelligent guardian" of food quality control.

1. Industry Background and Challenges: Why is visual inspection necessary for food and beverages?

The food and beverage industry has extremely stringent quality and safety requirements; even a 0.1% defect rate is unacceptable. Traditional quality inspection methods rely primarily on manual visual inspection, but human visual inspection has significant limitations.

In high-speed production environments, workers are prone to visual fatigue, leading to increased missed inspection rates. For example, at Budweiser, despite its high emphasis on product quality, a small portion of product packaging still relies on manual spot checks, which carries the risk of missed inspections, impacts efficiency, and poses challenges to product traceability. Furthermore, food and beverage products come in a wide variety of types, using a variety of packaging materials (such as transparent bottles, cans, and cartons), requiring complex and diverse inspections. From packaging integrity to fill levels, from label printing to production dates, inspection requirements are extremely detailed.

Faced with fierce market competition and increasingly stringent regulations, food and beverage manufacturers must seek more efficient and accurate inspection methods. Machine vision technology has emerged in this context.

2. Technical Principle: How Machine Vision "Sees" and "Judgments"

The basic principle of a machine vision system is to mimic human visual functions, achieving inspection objectives through the collaborative work of hardware and software. A complete machine vision system consists of a lighting source, optical lens, camera, image signal processing, and actuators.

The lighting source is the foundation of the entire system. An excellent lighting system can faithfully reproduce product colors, maintain uniform brightness across the entire illuminated area, and highlight object features, increasing contrast. Different inspection targets require different lighting designs. For example, when inspecting instant noodle packaging film, the reflective properties of the film must be specifically considered.

The optical lens and camera are responsible for capturing the image. Lens quality affects the system's ability to distinguish objects, while cameras convert optical information into electrical information. Current industrial cameras have a resolution of up to 25 megapixels, capable of capturing extremely subtle defects.

Image processing and analysis are the core of the system. Through preprocessing, feature extraction and recognition, and measurement, the computer compares the captured image with a standard template, identifies differences, and determines whether the product is acceptable. Modern systems also incorporate deep learning and AI algorithms to enhance their ability to identify complex defects.

3. Application Scenario: Comprehensive Application of Visual Inspection in Food and Beverage

Packaging Integrity Inspection

Visual inspection systems can identify various packaging defects, such as damaged packaging, defective labels, and missing production dates. For boxed or bagged foods, the system can verify the integrity of the outer packaging; for bottled products, it can detect missing or skewed caps.

Dongguan Chuangshi Automation Technology Co., Ltd.'s solution demonstrates that defect detection on the plastic packaging film of instant noodles can effectively identify defects such as holes, burns, and wrinkles, ensuring product quality.

Food Quality Inspection

Vision technology can be directly applied to assess the quality of food itself. For example, instant noodle crackers can be inspected for dirt or burn marks caused by overheated oil. In fruit grading, vision systems can automatically sort by size, color, and shape.

Based on the optical properties of food, vision systems can also determine the freshness of food by color. For example, UV photography can be used to detect surface damage on citrus fruits or assess the freshness of vegetables.

Label and Inkjet Printing Inspection

Label inspection is a key application area for vision technology. A US food company demonstrated that a vision system can inspect over 20 different product labels, verifying the correctness of the label graphics and barcodes, and ensuring label positioning within a ±2mm tolerance.

For printed information such as production date and expiration date, vision systems ensure that every package is clearly labeled. Banner's iVu system uses a matching tool to detect the presence of printed information, automatically rejecting products with missing codes.

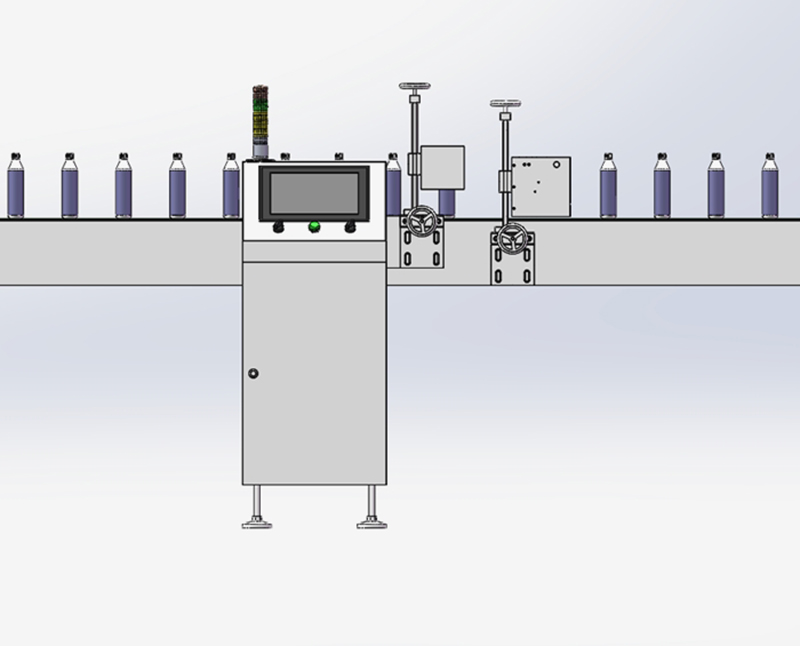

Filling and Cap Inspection

In the beverage industry, vision systems can inspect consistent fill levels and the presence of foreign matter in bottles to ensure consistent product quality. Bottle cap inspection includes checking for leaks and skew, among other things.

Budweiser's high-precision AI vision system can simultaneously perform comprehensive inspections for cap sealing, liquid level, inkjet coding, and label positioning, comprehensively ensuring product quality.

Composition and Integrity Inspection

Vision technology can also be used to inspect the internal composition and integrity of products. For example, it can verify the integrity of medication granules within a blister pack, or check the completeness of various toppings (oil, topping, powder, and vegetable) within an instant noodle package.

Banner's vision solutions can even verify the presence of instructions within the packaging, ensuring the integrity of each individual package.

4. Implementation Key Points: Key Factors for Successful Vision Inspection System Deployment

Light source and lighting design are crucial to a successful system. Different inspection targets require different lighting methods. For example, when inspecting instant noodle cakes for cosmetic defects, a combination of side-mounted area light sources and tunnel array light sources is used to ensure uniform illumination of the inspection surface.

Camera selection is also crucial. Choose the appropriate camera type (line scan or area scan) and resolution based on your inspection needs. For high-speed production lines, line scan cameras are more suitable for imaging uniformly moving objects.

System integration and flexibility are key features of modern vision systems. For example, the label inspection system developed by EPIC Vision Systems for a food company can complete product changeovers in less than two minutes and adapt to the inspection needs of different label types.

Algorithm and software capabilities directly determine inspection performance. Modern vision systems, combined with deep learning algorithms, can adapt to inspection scenarios involving different bag positions and tilt angles, improving recognition accuracy.

5. Case Study: Practical Application of Visual Inspection Technology

Budweiser's High-Precision AI Vision System

Budweiser's Foshan factory has introduced Hikvision Robotics' high-precision AI vision technology and independently developed inspection equipment to achieve fully automated inspection. The system, comprised of a 25-megapixel industrial camera and a VM algorithm platform, achieves millisecond-level inspection speeds.

This system enables comprehensive quality monitoring, including simultaneous inspection of multiple scenarios, including cap sealing, liquid level, code detection, label positioning, and bottle impurities on the filling line. The project reduced overall costs by 70%, setting a cost-effective and innovative benchmark for intelligent upgrades in the beer industry. Multi-stage Inspection in Instant Noodle Production

Dongguan Chuangshi Automation's solutions cover multiple stages of instant noodle production: packaging film defect detection, noodle surface defect detection, topping presence detection, and fork presence detection.

Specific imaging solutions are designed to address the unique characteristics of each stage. For example, to inspect toppings, a 160W color camera paired with a side-mounted area light source, combined with a deep learning algorithm, accurately determines the presence of toppings in different locations and colors.

Bottled Corn Syrup Label Inspection System

A US food company, in collaboration with EPIC, developed a label inspection system using two Cognex vision systems, capable of inspecting over 500 bottles per minute. The system can verify over 20 different labels, ensuring the correct placement and design of the label patterns and barcodes.

The system features a simple product changeover process; operators can quickly adapt to new product types by simply selecting the appropriate inspection program through the human-machine interface, significantly reducing production line downtime.

6. Future Trends: The Development of Intelligent Visual Inspection

With advances in artificial intelligence and machine learning technologies, visual inspection systems are becoming increasingly intelligent and adaptive. Deep learning algorithms enable systems to identify more complex defect patterns, continuously improving inspection accuracy.

The application scope of 3D vision technology is expanding. For example, Basler's 3D ToF (Time of Flight) cameras can be used to identify and sort fruit, enabling more accurate quality assessments.

Data analysis and traceability are also becoming key growth points for vision systems. Systems record large amounts of production data during inspection, facilitating quality analysis and traceability in factories. For example, Budweiser's vision systems improve product quality control.

Miniaturization and integration are another key trend. Banner's P5 iVu series image sensors integrate lighting and lenses, and feature a built-in touchscreen, allowing for PC-free programming and greatly simplifying the operation process.

With continuous technological advancements, the application of visual inspection in the food and beverage industry is expanding from single-point quality inspection to full-process quality control. Future vision systems will be more than just "inspection tools"; they will become intelligent nodes connecting production and management.

From the receipt of raw materials to the shipment of finished products, visual inspection technology plays an indispensable role in every link of food and beverage production, safeguarding the quality and safety of every product and providing consumers with greater peace of mind.