PE Bottle Squeeze Leak Detection Machine

1.Using acoustictechnology, non-contactandon - ine"knock" detection, the maximumspeedis up to 72000BPH

2.The hardware circuit and the embeddedoperating system is adopted to ensure stable operation for a long time

I. Product Introduction

1. Performance Description

The MT-PE-XL-S2-01 is a fully automatic PE/PET bottle leak detector. It utilizes dual sensors and can detect up to 600 bottles per minute. It employs a contact-based online detection method, directly and accurately reflecting the pressure characteristics within the product container, and the sampling data is stable and reliable. Its detection accuracy exceeds that of its domestic and international counterparts. Its core technology is belt squeeze detection, developed through over 10 years of experimentation and exploration. A flexible belt carries the product cans (or bottles) for transport. Sensors mounted on the side of the belt sense the pressure within the cans (bottles). A controller then converts this pressure into a digital signal, which is then processed to reflect the product's internal pressure and quality.

2. Applicable Inspection Objects

1).Aluminum cans filled with liquid nitrogen

2).PE/PP/PE plastic bottles containing gas or steam

3).Other gas-containing containers (excluding CO2)

3. Equipment Inspection Functions

1).Pressure detection

3).The inspection system automatically rejects products exceeding the specified rejection threshold based on user-defined rejection criteria。

4. Performance and Parameters

1).Adaptively tracks product line speed, allowing the machine to stop when the line stops, preventing bottles/cans from being jammed and exploding during idling.

2).Maximum inspection speed over 600 bottles/minute

3).Supports high- and low-pressure product inspection

4).High-speed impacting

5)Human-machine interface operation

6).Real-time dynamic display of multiple rejection data sets

7).Impact light alarm function

8).Chinese language menu

9).Maotong's unique DSP digital signal processing algorithm

10).24-hour remote assistance function

11).Continuous rejection shutdown

5. Detection Accuracy

1) Detection range: 0.08 to 0.5 MPa

2) Accuracy better than 0.02 MPa (Excessive vertical vibration of the conveyor chain will affect detection accuracy)

3) Rejection rate: ≥99.99%

4) False reject rate: ≤0.03%

PE bottle detection accuracy:

serial number

| Test items

| Testing conditions and accuracy

| Rejection rate

| False kick rate

|

1 | Leak detection | -- | -- | |

1.1 | Air leakage detection | Visible air leakage at the aluminum film or the filling capacity is too low, or the pore size is >0.8 mm

| >99.99% | ≤0.03 % |

1.2 | No cover detection | -- | >99.999% | |

Note: Rapid temperature changes and uneven bottle wall thickness can affect inspection results and cause false rejections. For best results, we recommend inspecting on a single-row conveyor belt exiting the sterilizer or where product temperature is uniform. The final interpretation rights belong to Maotong. | ||||

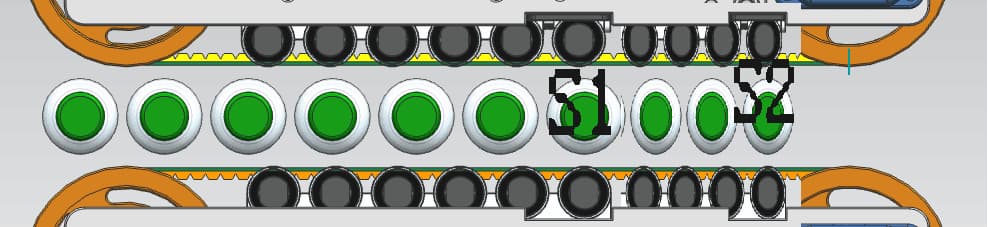

6. Schematic diagram of equipment extrusion

We add a guide mechanism at the front end to pre-squeeze the PE bottle to keep it at a certain pressure. If there is a leak, we will release the pressure as fully as possible. After the bottle is pre-pressed by the machine for a period of time, sensor S1 obtains pressure 1 inside the bottle. The bottle passes through the sensor S2 at the tail end of the machine to measure the pressure and obtain pressure 2 inside the bottle. The two pressure values are compared to determine whether the bottle is leaking.

7. Equipment detection principle

When a product passes the belt, it passes the positioning sensor, which detects its arrival and records the product's identification number and the current encoder signal through the control unit. The positioning sensor triggers the force sensor to measure the instantaneous pressure exerted by the product against the belt. This pressure data is then transmitted to the Maotong signal processing board via the network. The signal processing board processes and analyzes the received pressure data, transmitting the results to both the human-machine interface for dynamic display and the control unit. Upon receiving a rejection signal, the control unit notifies the rejector to remove the product with the corresponding identification number that fails the pressure requirement.

II. Equipment Installation

1. Equipment Loading, Unloading, and Storage

During transportation, the equipment must be secured and packaged, with particular attention to preventing the sensor from being subjected to pressure or tension. The exterior of the equipment must be wrapped with moisture-proof, impact-resistant material to prevent scratches, dents, and moisture. The equipment must be secured to the transport vehicle to prevent damage during movement. When unloading the equipment, use specialized loading equipment and ensure that the equipment is securely mounted on the loading equipment to prevent slipping. During use and storage, the ambient environment must meet certain requirements: relative humidity should be between 10% and 80%, and temperature between 0°C and 50°C.

2. Installation Specifications

2.1. Position the equipment horizontally, ensuring the clamping conveyor belt is parallel to the bottom conveyor belt of the product.

2.2. Before connecting the power supply, carefully check all cables for looseness and the grounding wire of the rack control box.

2.3. Connect the power supply correctly: single-phase AC 220V, 50Hz, total power 250W.

2.4. Connect the compressed air supply correctly: the pressure should be 4-8 bar, and the quality should meet industry standards.

2.5. For the most reliable testing, it is recommended that the product be tested after cooling down, and the equipment should be installed on a straight path 1.5-2m long.

II. Equipment Installation

1. Equipment Loading, Unloading, and Storage

During transportation, the equipment must be secured and packaged, with particular attention to preventing the sensor from being subjected to pressure or tension. The exterior of the equipment must be wrapped with moisture-proof, impact-resistant material to prevent scratches, dents, and moisture. The equipment must be secured to the transport vehicle to prevent damage during movement. When unloading the equipment, use specialized loading equipment and ensure that the equipment is securely mounted on the loading equipment to prevent slipping. During use and storage, the ambient environment must meet certain requirements: relative humidity should be between 10% and 80%, and temperature between 0°C and 50°C.

2. Installation Specifications

2.1. Position the equipment horizontally, ensuring the clamping conveyor belt is parallel to the bottom conveyor belt of the product.

2.2. Before connecting the power supply, carefully check all cables for looseness and the grounding wire of the rack control box.

2.3. Connect the power supply correctly: single-phase AC 220V, 50Hz, total power 250W.

2.4. Connect the compressed air supply correctly: the pressure should be 4-8 bar, and the quality should meet industry standards.

2.5. For the most reliable testing, it is recommended that the product be tested after cooling down, and the equipment should be installed on a straight path 1.5-2m long.