Can Body Seal Inspection Machine

1.Non contact online Inspection, no damage to the product.

2. Fast Inspection speed, up to 72000 cans/hour at the fastest.

3.360° online botle cap Inspection

4.Timely detect faults in the sealing machine to avoid producing a large number of defective products

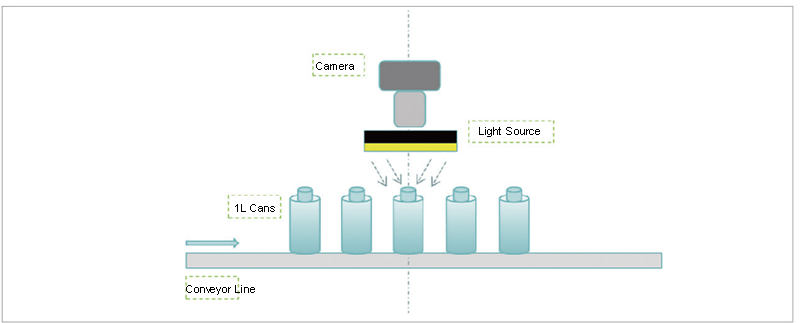

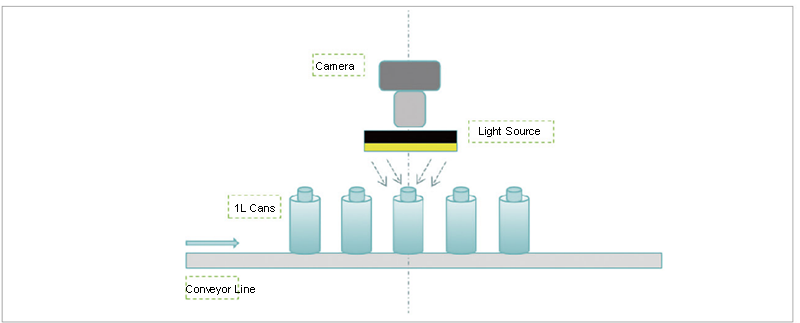

I. Project Overview

Project Name: Sealing Inspection System

Project Description: Performs sealing quality checks, detects defective products, and automatically rejects them from the production line.

Maximum Capacity: Up to 18,000 cans per minute

Applicable Can Size: 1L–2L

II. Environmental Conditions

Altitude Range: 5–3000 meters above sea level

Operating Temperature: 5°C–40°C

Relative Humidity: 50%–65% RH

Factory Requirements: Floor flatness and load-bearing capacity must comply with national standards to ensure stable machine operation.

Storage Requirements: After delivery, all equipment and components must be stored in compliance with national standards. During storage, lubrication and maintenance must be carried out to prevent surface damage or deformation that could affect installation, commissioning, and operation.

III. Production Requirements

Power Supply: 220V, 50Hz, single-phase (provided by the customer; special voltage requirements must be communicated in advance as they may affect equipment specifications, lead time, and pricing).

Total Power Consumption: Approx. 0.5 kW

Control Voltage: 24 VDC

Compressed Air: 4–12 bar (customer to provide air line connection from source to equipment).

IV. Key Features

Non-contact inspection – enables online detection without product damage.

User-friendly interface – color touchscreen HMI with intuitive controls.

Dual-side inspection – capable of verifying both inkjet codes and QR codes on cartons.

Modular architecture – supports system expansion and future upgrades.

High reliability – low failure rate with simplified maintenance.

2. Equipment mechanical components

model

| Name | Brief Description | Functional Description | Remark

|

1 | Distribution cabinet | It consists of an image processing computer, an interface processing computer, a strobe controller, a control system, an LED light source, an industrial camera, and sensors. | Supplies power to the entire system, processes images, and controls the rejection of defective products. | |

2 | Detection module | It primarily consists of solenoid valves and mechanical components. | Dynamically captures images | |

3 | Rejection device | Brief Description | Receives signals and controls the rejection of defective products. |

3. Electrical composition of the equipment

model

| Name | Model | quantity

| Notes |

1 | Image processing industrial computer | Intel 5 processor | 1 | Taiwan |

2 | Camera | Customizable full-view | 1 | Made in China |

3 | Camera IO module | 1 | Made in China | |

4 | Lens | Customizable all-around | 1 | Made in China |

5 | Camera cable | 1 | Customized | |

6 | DSP | MT-9000 | 1 | Customized |

7 | Touch screen | 1 | Taiwan | |

8 | Light source controller | OPT | 1 | Made in China |

9 | Light source | LISHI | 1 | Made in China |

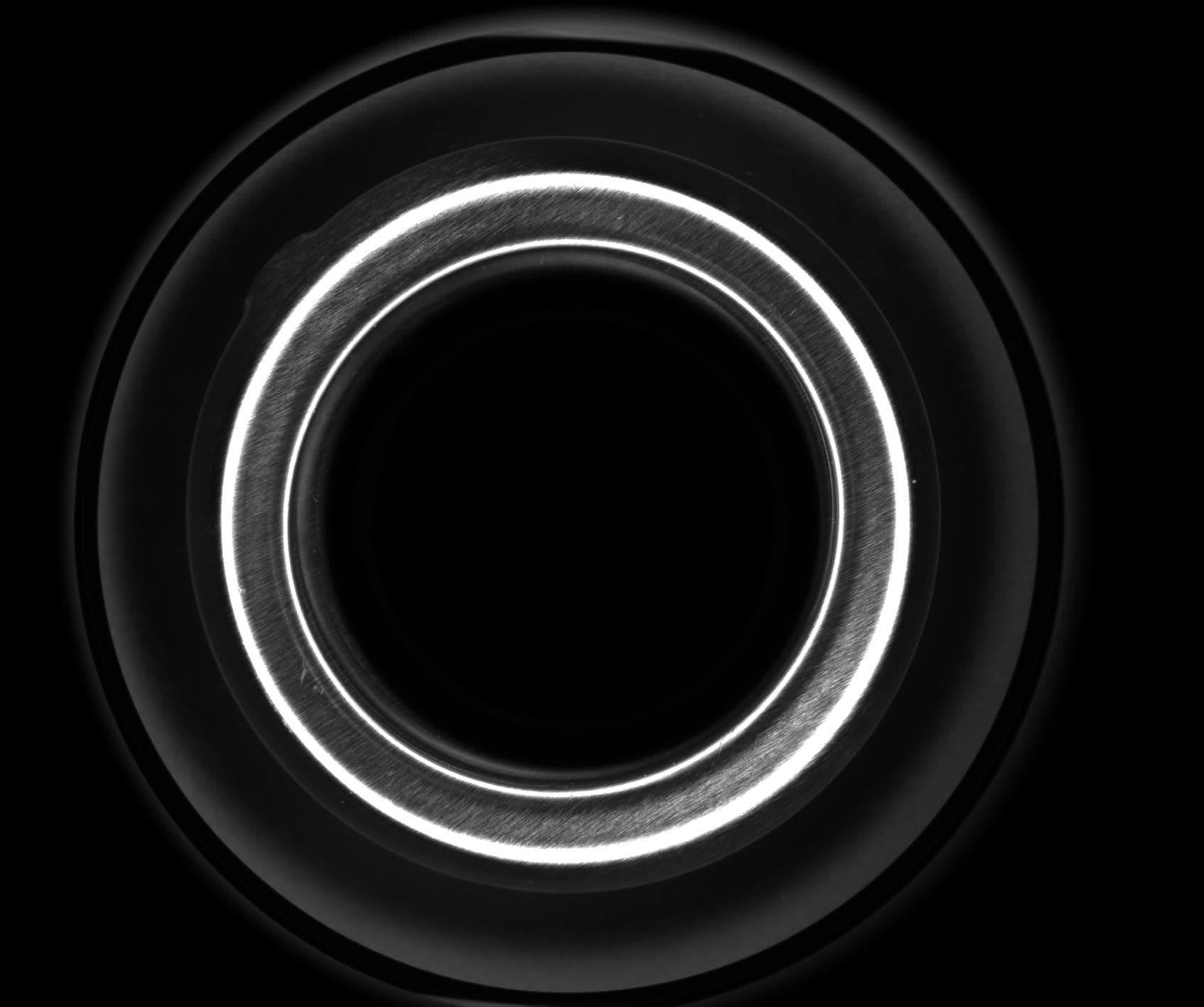

V. Inspection Principle:

1.A high-resolution camera and a 360-degree sidewall lens combination are used to photograph the sidewalls of the Sealing Inspection.

First, the bottle cap is accurately located, and a circular detection area is established at the edge of the sidewall in the image. If the bottle cap is poorly sealed, a noticeable grayscale value change will occur within the circular detection area. Based on the degree of grayscale change, an appropriate threshold parameter is set. If the grayscale value exceeds the threshold, the product is rejected as defective.

VI. Installation Requirements

The conveyor must be a single-row chain type with a total length of 1.8 meters. The conveyor section used for inspection should ensure that the bottle neck area remains clear, free from vibration and water droplets, as these factors can negatively affect the camera’s detection accuracy.

The slope of the inspection conveyor should not exceed 20°, and bottles must be spaced 3–5 mm apart during transport.

If noticeable vibration occurs at the bottle necks in the inspection area, a 60–80 mm clamping mechanism should be installed to stabilize the bottles and maintain reliable inspection results.