PP Bottle Leak Detection Machine

1.Using acoustic technology, non-contact and on-Iine "knock" detection, the maximum speed is up to 72000 BPH

2.The hardware circuit and the embedded operating system is adopted to ensure stable operation for a long time

2. Applicable detection objects

3. Performance and Parameters

1).Maximum inspection speed of over 300 bottles/minute

2).Adaptive product tracking

3).High-speed, accurate rejection of defective products

4).Human-machine interface operation

5).Light alarm upon impact

6).Chinese language menu

7).Maotong's unique DSP digital signal processing algorithm

8).24-hour remote assistance

9).Continuous rejection and shutdown

10).Applicable cap diameter: 20-200mm

11).Applicable bottle diameter: 25-250mm

12).Bottle height: ≤500mm

4. Detection Accuracy

1).Detection Rate: ≥99.99%

2).False Rejection Rate: ≤0.03%

5. Equipment Inspection Principle

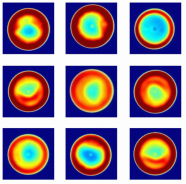

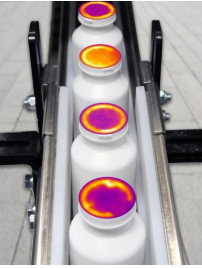

After electromagnetic heating of the aluminum foil, it melts the heat-sealing film, completing the seal. Heat is then transferred to the bottle cap through heat conduction. The heat distribution on the bottle cap surface is captured by an infrared thermal imaging camera. This heat distribution directly reflects the degree of compression between the gasket and the bottle cap, which indirectly reflects the seal quality. If a seal defect occurs, the heat distribution will be abnormal, as shown in the following relationship:

Causes of defects | Defect type

| heat distribution

|

Aluminum film problems | Missing,damaged, inverted

| Incomplete heat distribution

|

Capping machine problems | Loose cover, crooked cover

| The heat conduction between the aluminum diaphragm and the bottle cap is insufficient, and the temperature of the whole or part of the bottle is too low.

|

Electromagnetic sealing machine problems | False seal, over-seal

| The temperature is too high or too low |

After obtaining the thermal imaging image, different defects can be detected by combining it with Maotong image processing software methods.

II. Equipment Installation

1. Equipment Loading, Unloading, and Storage

During transportation, the equipment must be secured and packaged, with particular attention to preventing the sensor from being subjected to pressure or tension. The exterior of the equipment must be wrapped with moisture-proof, impact-resistant material to prevent scratches, dents, and moisture. The equipment must be secured to the transport vehicle to prevent damage during movement. When unloading the equipment, use specialized loading equipment and ensure that the equipment is securely mounted on the loading equipment to prevent slipping. During use and storage, the ambient environment must meet certain requirements: relative humidity should be between 10% and 80%, and temperature between 0°C and 50°C.

II. Equipment Installation

1. Equipment Loading, Unloading, and Storage

During transportation, the equipment must be secured and packaged, with particular attention to preventing the sensor from being subjected to pressure or tension. The exterior of the equipment must be wrapped with moisture-proof, impact-resistant material to prevent scratches, dents, and moisture. The equipment must be secured to the transport vehicle to prevent damage during movement. When unloading the equipment, use specialized loading equipment and ensure that the equipment is securely mounted on the loading equipment to prevent slipping. During use and storage, the ambient environment must meet certain requirements: relative humidity should be between 10% and 80%, and temperature between 0°C and 50°C.

2. Installation Specifications

2.1. For the most reliable testing, it is recommended to test the product after the electromagnetic sealer, and install the equipment on a straight path 1.5-2 meters long.

2.2. Before connecting the power supply, carefully check all cables for looseness and the grounding wire of the rack control box.

2.3. Ensure the power supply is properly connected: single-phase AC 220V, 50Hz, with a total power of 250W.

2.4. Ensure the compressed air supply is properly connected: the pressure should be 4-8 bar, and the quality should meet industry standards.

3. Equipment Structure and Appearance

3.1. Overall Dimensions: 600mm × 500mm × 1700mm

3.2. Frame Structure: 304 stainless steel, mounted on a conveyor belt

3.3. Weight: Approximately 50kg

III. Equipment Safe Operation Precautions

Before using this product, please refer to the following safety instructions:

3.1 Only personnel with general training may operate this equipment.

3.2 Only personnel with professional training may perform repairs on this equipment.

3.3 Ensure all safety warnings and protective devices are in place before operating this equipment.

3.4 Do not operate the equipment with the cover open. Open the cover only when the power and compressed air are turned OFF.

3.5 When the machine is running, keep your hands away from the connecting rod assembly of the reject cylinder.

3.6 When the machine is running, do not block or accidentally touch the photoelectric switch that triggers the product, as this may cause the reject cylinder to malfunction and injure someone.

3.7 When the machine is powered on, do not disconnect any electrical connections, as this may damage electrical components.

3.8 When servicing the machine, mark the equipment with a sign to prevent personal injury.

3.9 Before connecting external devices, ensure that both the device and the external device are powered off. After disconnecting the power cord and connecting the external device, turn on the power.

3.10 The electronic components within the machine are sensitive to static electricity, so the frame and control cabinet must be properly grounded.