Automatic Visual Inspection Machine

1.Use 4 cameras to take 360 photos and analyze the botle cap of BC Can, and automatically eliminate the defective products online

2.Suitable for BC series cans

I. Equipment Parameters and Site Description

1. Project Overview

1.1 Equipment Name: Online Inspection Machine for BC Can Caps

1.2 Description: The system adopts advanced machine vision technology to perform fully automated, non-contact online inspection of BC can caps. It detects defects such as broken bridges and cap deformations (including thread distortion and twisted bottoms).

1.3 Rated Capacity: 400 cans/min (standard configuration)

1.4 Applicable Container Types: Cans, BC Cans

1.5 Container Volume Range: 100 mL – 1000 mL

2. Environmental Conditions

2.1 Altitude Range: 5–3000 m above sea level

2.2 Recommended Operating Temperature: 5°C–40°C

2.3 Recommended Operating Humidity: 50–65% RH

2.4 Factory Requirements: Floor flatness, load-bearing capacity, and other conditions must comply with relevant national standards to ensure stable operation of the machine.

2.5 Storage Requirements: Upon delivery, all parts and equipment must be stored in compliance with national standards. During storage, appropriate lubrication and maintenance are required to prevent surface damage or deformation that may affect installation, commissioning, or operation.

3. Equipment Performance

Noise Level: ≤85 dB. Actual noise depends on container type, machine load, building acoustics, and related factors.

4. Power Supply

Main Power: 3 × 380 VAC ±10%, 50 Hz, 3 PH + N + PE

Lighting Power: 220 VAC, 50 Hz, single-phase

Control Voltage: 24 VDC

Total Power Consumption: Approx. 1.0 kW

(Special voltage requirements must be confirmed in advance; specifications, delivery schedules, and pricing may vary accordingly.)

II. Equipment Introduction

4.1 BC Can Cap Inspection Machine

Equipment Name: BC Can Cap Inspection Machine

Model: MT-YLG-PG-C4

Quantity: 1 Set

Rated Speed: 400 cans/min

Applicable Containers: Cans

Applicable Production Lines: Can and BC can packaging lines operating ≤400 cans/min

Installation Position: Single-lane conveyor, downstream of high-temperature sterilizer and air dryer

Function: Equipped with four cameras, the system performs 360° visual inspection of BC can caps and automatically rejects defective products online.

4.2 Operating Principle, Process & Installation

The inspection system utilizes synchronized vision capture and real-time image processing. Each can passes through the inspection zone where multiple cameras capture cap images from all directions. The images are analyzed by the vision processor; defective cans are identified and automatically rejected at the designated removal station. The system is installed in-line after sterilization and drying, ensuring reliable inspection without disrupting production flow.

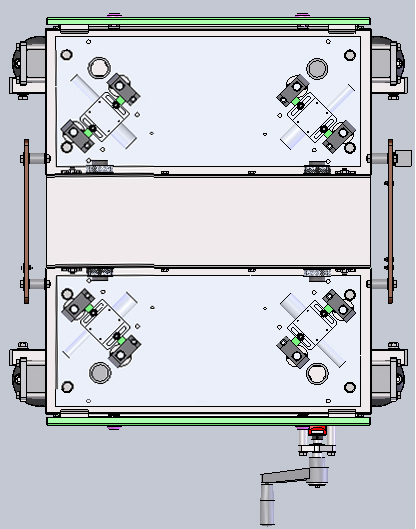

Equipment mechanical layout drawing

System Configuration Overview:

Workstation Function: Four cameras perform 360° image inspection of BC can caps.

Individual Module Inspection Description:

1. A can passes the positioning sensor, which detects its arrival and records the can ID and current encoder value via the control unit.

2. The positioning sensor instructs the camera to capture an image of the current milk powder can. After capturing the image, the image processor processes the image. The image processor transmits the processing results to the human-machine interface for dynamic display and to the control unit for rejecting unqualified cans.

3. Upon receiving the unqualified signal, the PLC instructs the rejector to reject the can with the corresponding ID.

4.3 Empty Can Detection Module:

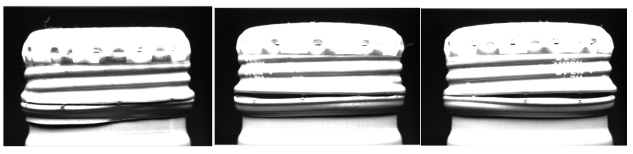

4.3.1 Detection Content and Accuracy: Image of Abnormal Product

Testing items

| Inspection Contents | nspection Accuracy | Rejection rate

|

Bottle cap detection

| No Cover | -- | ≥99.99% |

Broken Bridge | Gap spacing > 0.5 mm or disconnect at two points | ≥99.99% | |

Deformed Cover | Thread twisting or cap edge lifting | ≥99.95% | |

Broken Bridge | Disconnect at one point | ≥99.75% |