How Machine Eyes Protect Production Line Safety and Quality

Food and Beverage Visual Inspection: How Machine Eyes Protect Production Line Safety and Quality

On high-speed food and beverage production lines, a tireless "eye" safeguards product quality and safety around the clock. This is machine vision inspection technology—it mimics human vision and combines it with computer image processing and analysis capabilities to achieve precise control of the entire food and beverage production process. With increasing industrial automation and increasingly stringent food safety standards, visual inspection technology is becoming an indispensable quality assurance tool for the food and beverage industry.

I. Key Application Areas of Visual Inspection in Food and Beverage Production

1. Packaging Integrity Inspection

The integrity of food and beverage packaging is directly related to product hygiene, safety, and shelf life. Vision inspection systems can identify various packaging defects in real time, including damage to packaging materials, dents, and loose seals. For example, on beverage production lines, the system can accurately detect whether bottle caps are properly sealed, deformed, or stained, ensuring that product quality is not deteriorated due to packaging defects.

2. Appearance and Label Inspection

Product appearance and labeling are an important reflection of brand image and regulatory compliance. Vision inspection systems can automatically identify and verify information such as label position, print quality, production date, batch number, and barcode. Using OCR (optical character recognition) technology, the system can read the characters on the packaging, ensuring no missing, blurred, or misprinted codes, with a recognition rate exceeding 99.95%.

3. Liquid Level and Fill Volume Detection

For beverages, fill volume accuracy is crucial. Vision inspection technologies (including X-ray or optical technologies) can accurately measure the liquid level within the container to prevent underfilling or overfilling. This is particularly important for carbonated beverages, as low liquid levels can directly affect the taste of the product.

4. Foreign Object and Internal Defect Detection

Food safety is a top concern for consumers. Vision inspection systems can effectively identify foreign objects such as glass fragments, metal shavings, insects, and other impurities in products. X-ray inspection technology can even penetrate packaging to detect internal defects in food, significantly improving food safety. 5. Product Classification and Sorting

Based on image processing algorithms, visual inspection systems can automatically classify and sort products based on characteristics such as color, shape, and size. In applications such as fruit processing and meat sorting, the system can quickly distinguish between different grades of products, improving sorting efficiency and accuracy.

II. Technical Principles and Core Components of Visual Inspection Systems

A complete machine vision inspection system typically consists of the following components:

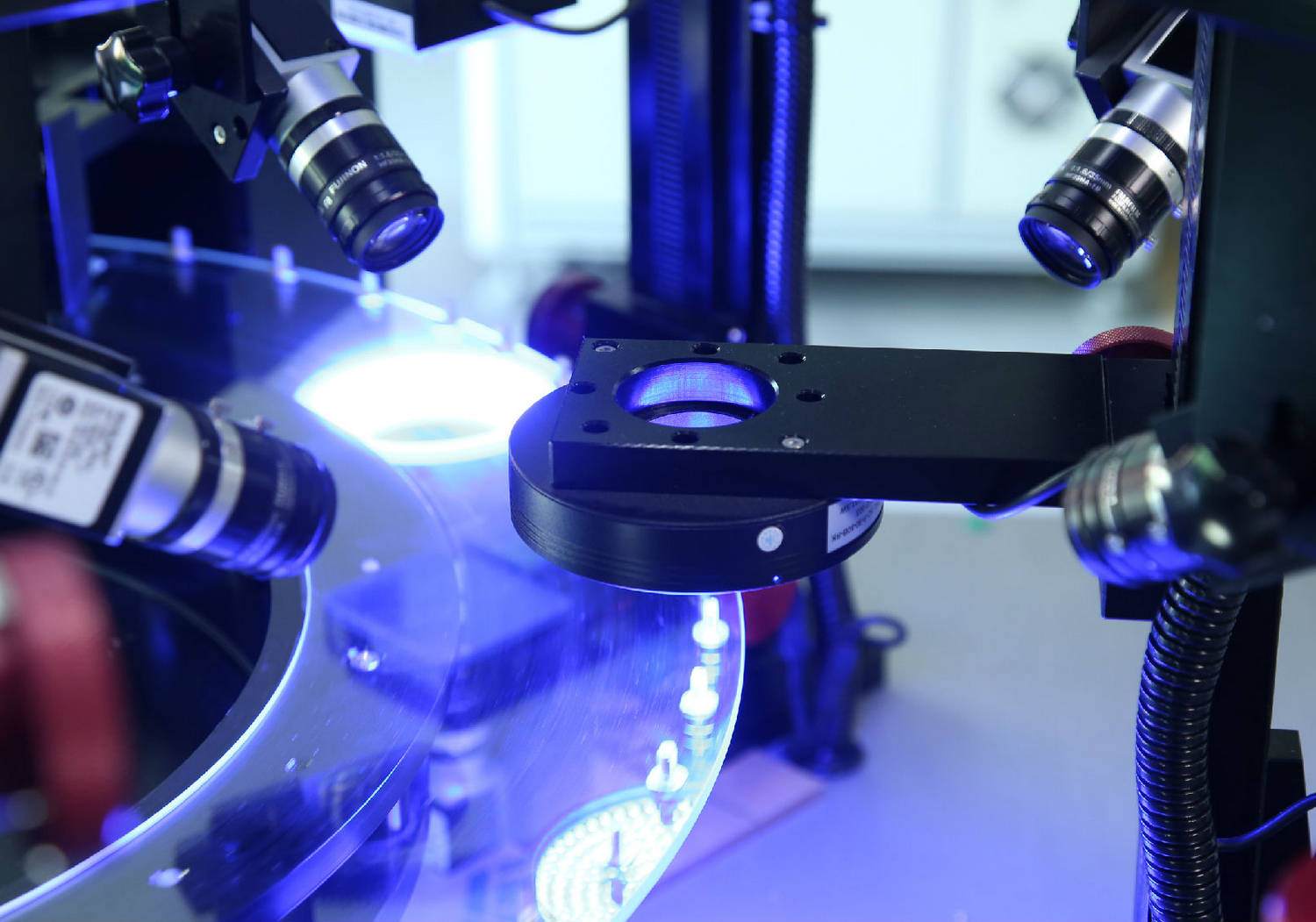

Imaging System: This includes hardware such as an industrial camera, lens, and light source. The choice of camera (such as CCD or CMOS) depends on the inspection requirements, while the design of the light source directly impacts image quality. A good lighting solution can highlight target features and reduce ambient light interference.

Image Processing Software: This is the "brain" of the visual inspection system, responsible for analyzing and processing captured images. Modern image processing software utilizes advanced algorithms, such as deep learning technology, to automatically learn product characteristics and improve defect detection accuracy.

Actuator: Based on the image processing results, the system automatically removes defective products through actuators such as pneumatic devices or robotic arms, achieving a closed-loop quality control system. With technological advancements, modern visual inspection systems have also integrated advanced technologies such as artificial intelligence, 3D vision, and ultra-high-definition imaging, further enhancing their inspection capabilities and scope of application.

III. Advantages and Value of Visual Inspection Technology

Compared to traditional manual inspection, visual inspection technology offers significant advantages:

High Efficiency and Continuity: Visual inspection systems can operate 24/7, easily matching the pace of high-speed production lines. For example, some systems can inspect hundreds or even thousands of components per minute, far exceeding the human eye's detection limits.

High Accuracy and Stability: This eliminates misjudgments and missed inspections caused by human eye fatigue, experience differences, and subjective factors. Machine vision systems maintain consistent inspection standards, ensuring consistent product quality.

Reduced Costs and Waste: While requiring an initial investment, long-term visual inspection systems can significantly save labor costs and reduce raw material waste through early detection of defective products, thereby improving overall production efficiency.

Data Traceability and Analysis: Visual inspection systems can record various data during the inspection process, providing a basis for product quality analysis and production process optimization, enabling data-driven, refined management. IV. Technological Development Trends and Challenges

1. The Fusion of Artificial Intelligence and Deep Learning

Artificial intelligence technology is driving the development of more intelligent visual inspection systems. Deep learning algorithms, trained on large datasets, can automatically learn complex defect characteristics, improving their ability to identify irregular and emerging defects. For example, some AI vision systems can now inspect two cans of milk powder per second with 100% accuracy.

2. 3D Vision and Multi-Sensor Technology

Traditional 2D visual inspection has limitations, while 3D vision technology provides in-depth information about the product, enabling more comprehensive defect detection. Multi-sensor fusion technology (combining vision, infrared, and ultrasonic sensors) further improves inspection accuracy and reliability.

3. Standardization and System Integration

With the widespread adoption of visual inspection technology, the development of a standardization system has become a key focus in the industry. This includes the development of technical standards, inspection method specifications, and equipment standards, as well as the improvement of data security and privacy protection measures.

4. Challenges

The application of visual inspection technology in the food and beverage industry still faces several challenges: Product diversity requires greater adaptability in inspection systems; increasing production line speeds place higher real-time demands on inspection systems; and inspection accuracy in complex environments still needs to be further improved.

5. Future Outlook

With the advancement of Industry 4.0 and smart manufacturing, the application of visual inspection technology in the food and beverage industry will become more extensive and in-depth. Future development trends include:

More efficient real-time inspection systems to meet the demands of high-speed production lines;

More intelligent defect recognition algorithms to reduce false positives and missed detections;

More flexible modular designs to accommodate high-variety, small-batch production models;

Deep integration with industrial Internet platforms to achieve full-process quality monitoring and traceability.

As a key guarantee for food safety and quality control, visual inspection technology will continue to drive the food and beverage industry towards greater intelligence, automation, and digitalization, providing consumers with safer, higher-quality products.

From raw material inspection to finished product packaging, from label recognition to foreign object removal, visual inspection technology has become the "eagle's eye" of quality control in the food and beverage industry. As technology continues to advance, this "machine eye" will become more sensitive and intelligent, continuing to protect the safety and quality of food and beverages.