What are the applications of visual inspection in dairy production?

Visual inspection technology has penetrated every stage of dairy production, from packaging materials to finished product shipment. Its core goal is to improve the accuracy and efficiency of quality control. The following table summarizes the main application scenarios and technical highlights of these technologies.

Application Phase | Inspection Object/Scenario | Main Inspection Content/Defect Type | Core Technology/Features |

Packaging Material Inspection | Printed packaging materials (such as aluminum foil) | Detect printing defects such as dirt, missing prints, pulled lines, offset overprinting, missing hot stamping, and scratches | High-speed inspection (up to 800 m/min), high imaging accuracy (0.15 mm x 0.15 mm/pixel) |

Filling and Sealing Inspection | Empty bottles (glass bottles, etc.) | Detect abnormal bottle shapes, inverted bottles, cracked openings, foreign objects, damaged bottle openings, and dirt | Container quality screening before filling to eliminate unsuitable containers |

Liquid Level Detects | whether the filling level meets the standard | X-ray or optical technology determines the fill volume | |

Aluminum Foil Sealing Detects | missing, curled, misaligned, or poorly sealed aluminum foil | Ensures product sealing and prevents secondary contamination | |

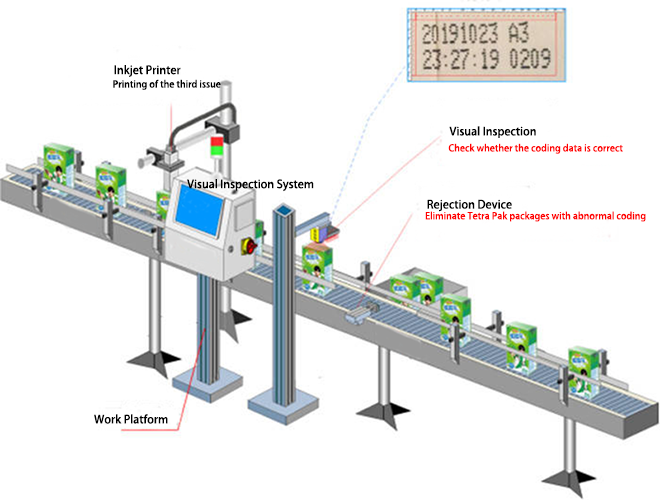

Packaging Label Inspection | Inkjet codes such as production date and batch number Detects | missing, blurred, overlapping, or misprinted codes | Machine vision (OCR character recognition) achieves a recognition rate exceeding 99.95%. AI deep learning can inspect two cans of milk powder per second with 100% accuracy |

Label inspection | Absent labels, high and low labels, perforated labels, and horizontally offset labels | ensure accurate and aesthetically pleasing product packaging information | |

Bottle caps | Missing, high, crooked, broken, mismatched, or have color variations | ensure the seal and appearance of the package | |

Foreign object and internal defect inspection | Product interior inspection | Foreign objects such as metal, glass, bone, plastic, and rubber; fill volume inspection; and product morphological integrity inspection | X-ray inspection technology, which can penetrate packaging, is optimized for the high-protein and high-fat characteristics of dairy products to reduce misjudgments |

Finished Product Packaging and Palletizing | Final finished cartons/boxes | Poorly printed packaging, deformation, barcode misalignment, and other defects | Inspected by AI-powered vision, guiding robots to automatically reject, box, and palletize |

The value and trends of visual inspection

The widespread application of visual inspection technology in the dairy industry has brought about improvements in many areas:

Improving Quality and Safety: High-precision, high-speed automated inspection replaces fatigue-prone and error-prone manual inspections, significantly reducing missed inspections and effectively preventing defective or safety-unsafe products from entering the market.

Increasing Efficiency and Reducing Costs: Vision systems can adapt to high-speed production lines (e.g., inspection speeds up to 800 meters per minute), improving production efficiency while significantly reducing labor costs.

Enabling Data Traceability: Data generated during the inspection process can be integrated with manufacturing execution systems (MES), enabling real-time monitoring and traceability of quality data, providing a basis for production process optimization.

The future trend is the deep integration of artificial intelligence (AI) and industrial internet platforms. For example, Jinan Maotong's AI visual inspection system, through deep learning, can automatically identify and reject products with incorrectly printed codes with 100% accuracy. This makes quality control more intelligent and precise.

We hope the above information provides you with a comprehensive understanding of the application of visual inspection in dairy production. If you would like to learn more about a specific process or technology, we can continue the discussion.