Company News

In industries such as beverages and pharmaceuticals, precise liquid level control is crucial for product quality and corporate reputation.Accurate detection of liquid levels in glass bottles has become a critical aspect of modern industrial production. Traditional manual visual inspection methods

2026/01/27 13:13

The tiny, almost invisible cracks on the packaging bag may be the culprit behind spoiled and leaking seasonings.On supermarket shelves, packaged seasonings are popular with consumers due to their convenience and affordability. However, behind this packaging lies a frequently overlooked quality risk

2026/01/24 16:17

On high-speed modern production lines, precise quality control is a crucial line of defense for protecting corporate reputation and consumer safety.As the "quality gatekeepers" on the production line, full-box weighing and inkjet code visual inspection technologies, from the dimensions of weight

2026/01/23 14:09

IntroductionCeramic bottles, as an important packaging material for Baijiu (Chinese liquor), have their integrity directly related to the product's sealing and quality. However, the inherent brittleness of ceramic materials and the complexity of the manufacturing process easily lead to defects such

2026/01/19 12:47

If carton-packaged milk leaks, it not only causes waste but also potentially means that external bacteria have entered, posing a food safety risk. Currently, leaks are mainly detected using the following principles and methods:🔍 Common Leak Detection MethodsCurrently, the following methods are

2026/01/08 23:16

Automated, high-precision visual inspection systems for pharmaceutical bottles are becoming a key technological support for ensuring the quality of pharmaceutical packaging.In the pharmaceutical industry, the quality of drug packaging directly relates to patient safety. Traditional manual

2026/01/08 22:42

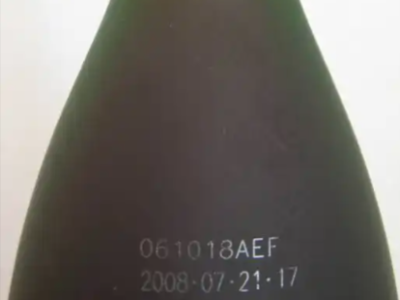

On high-speed canning production lines, an invisible light silently guards the identity of each product.In the modern food industry, glass bottles and jars are important food packaging methods, and the printed code information on their packaging directly relates to product quality traceability,

2026/01/06 16:46

1. IntroductionIn today's highly automated industrial production environment, glass bottles, as important packaging containers for numerous industries such as pharmaceuticals, beverages, and cosmetics, have their appearance quality and the accuracy of their identification information directly

2026/01/06 14:33

In the beverage and pharmaceutical industries, the accuracy of liquid levels in PET plastic bottles is crucial for product quality and production costs. X-ray detection technology is becoming a key tool in ensuring this accuracy.In the food and beverage and pharmaceutical industries, PET bottles

2026/01/05 16:33

Behind the small inkjet code lies a vast quality control system.In industries such as food, pharmaceuticals, and cosmetics, 1L tinplate cans are a common packaging form, favored for their excellent sealing and corrosion resistance. Inkjet printing, as a carrier of product identification and

2026/01/04 10:43

In today's world, where food safety is a major concern, a single tiny foreign object can lead to a crisis of trust for an entire brand. Visual inspection technology is becoming an indispensable guardian of quality in the food industry.Rice noodles, a traditional staple food in China, have a safety

2025/12/31 10:29

Seasoning oil packets are an indispensable component of the modern food industry, and their sealing integrity and quality directly affect product safety and user experience. Traditional leakage detection methods mainly rely on manual visual inspection or simple sensing technologies, which suffer

2025/12/30 11:20