Logistics Box Inkjet Detection Machine

1.Non contact online Inspection, no damage to the product.

2.The Inspection speed is fast, reaching up to 100 boxes per minute at the fastest.

3.Equipped with Al self-learning function to ensure the reliabilty of Inspection

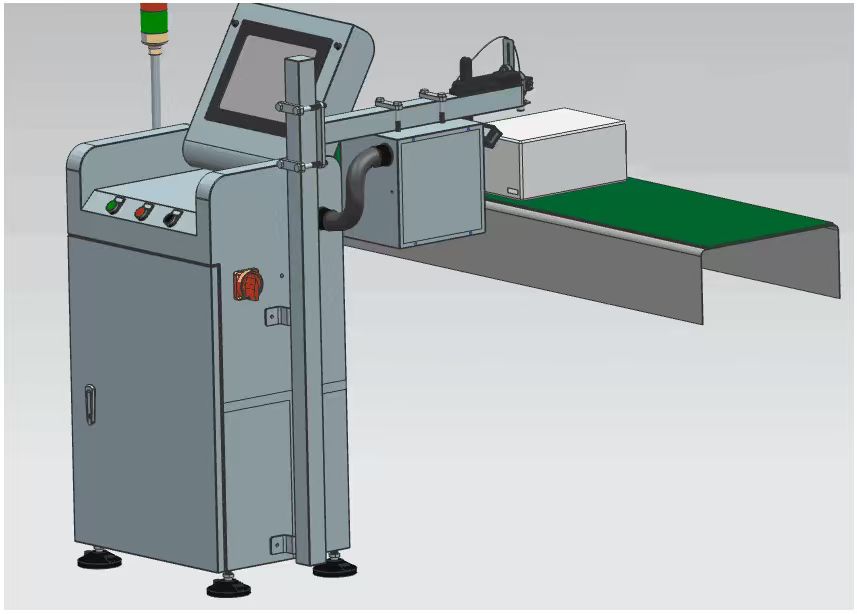

I. Equipment Introduction

1. Equipment Application:

Online inspection of carton coding quality on beverage carton production lines, automatically rejecting defective cartons.

2. Equipment Features:

◆ Non-contact, online inspection, no damage to products.

◆ High inspection speed, up to 60 cartons/minute.

◆ Flexible human-machine interface with multi-level user access.

◆ Customizable functions based on actual on-site production conditions.

◆ Automatically stores photos of defective cartons daily, with customizable storage time.

◆ 24-hour remote service.

◆ Continuous machine downtime rejection.

II. Detection Functions

1. Presence of inkjet printing (missing inkjet printing)

2. Blurred inkjet printing (the inkjet printer causes the characters to be blurred and difficult for the human eye to discern)

3. Missing characters (a single character is missing more than 30%)

4. Position deviation (outside the set range)

5. Deformed inkjet printing (curved inkjet printing, long or short inkjet printing, etc.)

6. Incorrect inkjet printing (wrong date, factory code, or security code)

3. Installation location

On-site installation location conditions: 1.5-2 meters straight behind the inkjet printer.

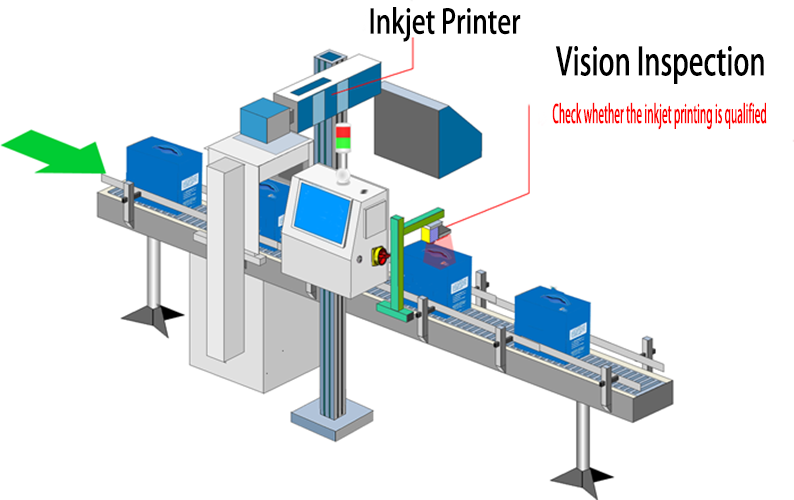

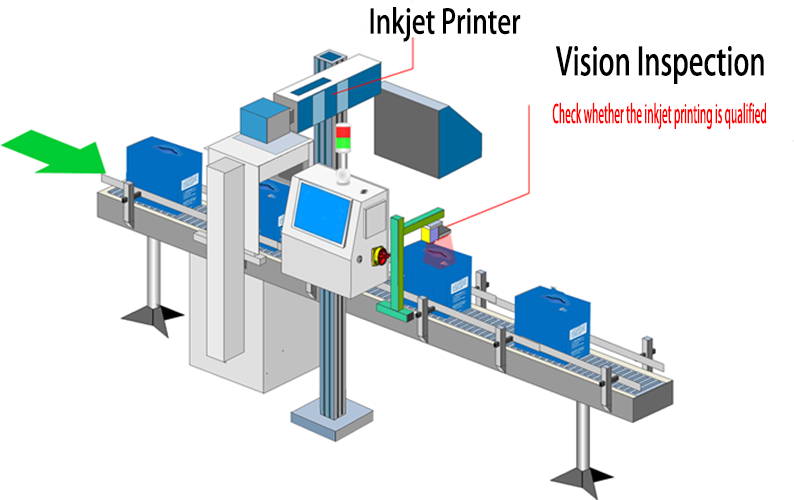

4. Detection principle

A Gigabit digital camera is used to take pictures from top to bottom/side to collect pictures of the carton coding. The pictures are digitally analyzed and the cartons with unqualified coding are automatically and accurately removed online.

When a box passes the positioning sensor, its arrival is detected and the control unit records the box identification number and the current encoder signal. The positioning sensor triggers a digital camera to capture an image of the current box's coding and transmits it to the image processor via the network. The image processor processes and analyzes the received image and transmits the results to the human-machine interface for dynamic display and to the control unit. Upon receiving the unqualified coding signal, the control unit notifies the rejector to remove any boxes with unqualified coding corresponding to the identification number online.

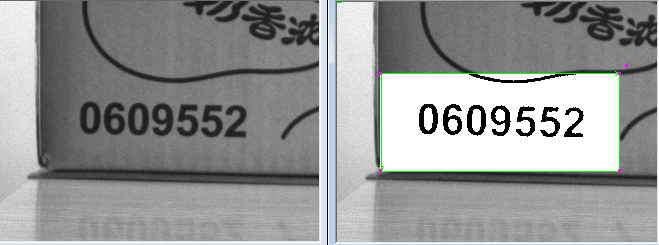

Sample image processing effect, the left is the original image, the right is the processed image

V. Equipment Configuration Details and Inspection Accuracy

(I) Detailed Equipment Description

C. Technical Parameters

Equipment Name: Carton Inkjet Printer

Model Name: MT-ZX-OCR

Applicable Production Speed: 60 cartons/minute

Inspection Area: Inkjet Printer

Rejection Method: Automatically and accurately rejects cartons with defective inkjet prints detected by the inspection unit.

Safety Protection Rating: IP65

D. Main Applications:

Widely used in carton production lines, inspects and automatically rejects inkjet prints on cartons of various colors.

C. Technical Features:

1. Reduces personnel requirements and reduces production costs.

2. Improves production efficiency and product quality.

3. Inkjet print inspection results meet manufacturer's relevant technical standards.

E.Detection accuracy:

serial number

| Inspection Items | Detection Conditions and Accuracy | Rejection rate

| False kick rate

|

1 | Inkjet Printing Inspection | -- | -- | < = 0.03% |

1.1 | No inkjet printing | -- | >99.99% | |

1.2 | Missing inkjet printing | Single character > 30% | >99.8% | |

1.3 | Fuzzy inkjet printing | Indecipherable characters to the human eye | >99.93% | |

1.4 | Incorrect inkjet printing | Incorrect production date, incorrect factory code, incorrect security code, deformation (elongation or shortening) | >99.99% | |

1.5 | Position deviation | Exceeding the expansion zone | >99.99% | |

1.6 | Duplicate inkjet printing | Multiple codes printed within the code area | >99.99% |

Note: The rejection rate of the test item "no coding" described in the table means that out of 10,000 bottles of unqualified products without coding, there may be 1 box that is not rejected after being tested by the equipment. This is only theoretical experimental data, and the same applies to other test items.