Bottle Mouth Defect Inspection Machine

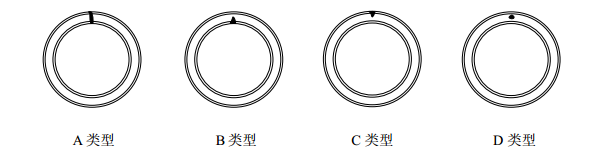

1.Double evaluation ring technology to detect bottle mouth reliablely and stablely

2.The bottle mouth image is divided into several grades, and the evaluation method is accurate and precise

3.Using an independently developed image processing system, the maximum speed is up to 60000 BPH

1. Project Overview

1.1 Project Name: Online Bottle Finish Inspection Machine

This system adopts advanced machine vision technology to automatically and non-contactly inspect deformation and defects at the mouths of glass bottles during production.

The rated capacity of the equipment is 48,000 bottles per hour.

Operating Environment:

Recommended Altitude: 5–3000 meters above sea level

Recommended Temperature: 5°C – 40°C

Recommended Humidity: 50% – 65% RH

Factory Requirements:

The workshop floor must meet national standards for levelness and load-bearing capacity to ensure stable operation of the equipment.

Storage conditions must comply with national standards. Upon delivery, equipment and parts should be placed in appropriate storage areas.

During storage, lubrication and routine maintenance must be carried out to prevent surface damage, corrosion, or deformation that may impact installation, commissioning, and operation.

Equipment Production Conditions

Noise Level: ≤85 dB. (Actual noise may vary depending on container/package type, machine power, building acoustics, and other factors.)

Power Supply:

Main Supply: 3 × 380V AC ±10%, 50 Hz, 3PH+N+PE (connection between customer’s main electrical cabinet and equipment cabinet).

Auxiliary Lighting: 220V, 50 Hz, single-phase.

Control Voltage: 24 VDC.

Total Power Consumption: Approx. 1.0 kW.

Note: Special voltages require prior confirmation; equipment specifications, delivery time, and pricing may be affected.

Compressed Air: 4–6 bar (customer to provide air line connection from air source to equipment main unit).

Equipment Overview

4.1 Bottle Finish Inspection Machine

Equipment Name: Bottle Finish Inspection Machine

Model: MT-PK021

Quantity: 1 set

Production Capacity: 48,000 bottles/hour

Applicable Containers: PET/PE bottles

Applicable Production Line: 48,000 bottles/hour

Installation Location: Installed inside the blow molding machine, either at the bottle exit point from the mold or along the conveyor chain.

4.2 System working principle and process

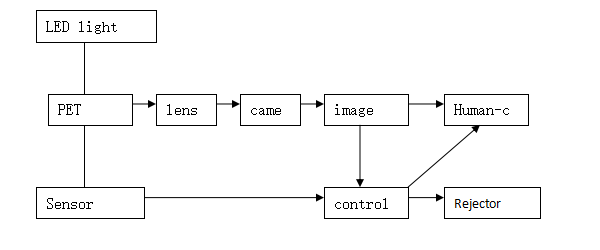

Figure 4: System working principle and flow chart

System Operating Principle and Workflow

As each bottle moves along the conveyor, it passes through a positioning sensor. The sensor detects its presence and, via the control unit, records both the bottle ID and the current encoder signal.

The positioning sensor then triggers the camera to capture an image of the bottle finish. The captured image is processed by the image processor, and the results are simultaneously sent to the human–machine interface (HMI) for real-time display and to the control unit for subsequent rejection processing.

When the control unit receives a signal indicating that a bottle is defective, it instructs the rejector to automatically remove the identified bottle from the production line.

4.3 Image Acquisition Components

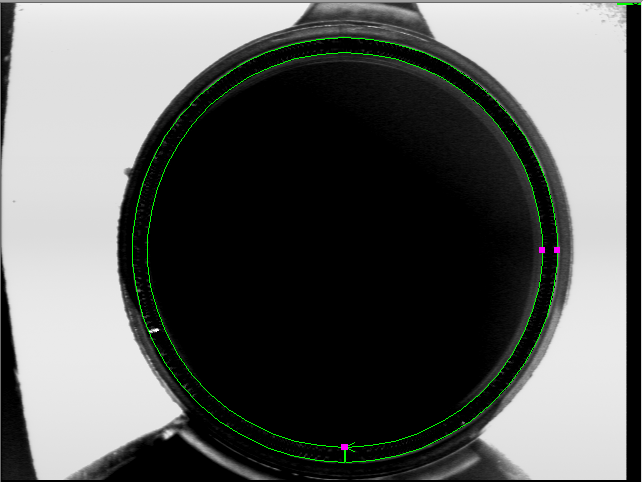

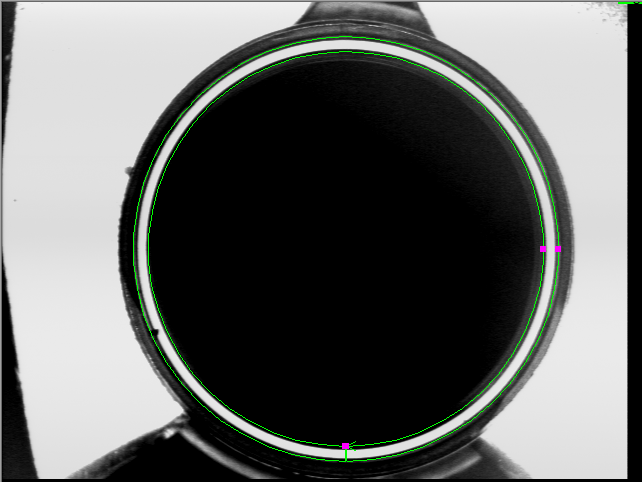

Light Source:

Equipped with an LED area light source with a service life of up to 30,000 hours. By applying foreground illumination, the bottle finish appears as a continuous bright ring, clearly revealing any defects. A fixed-focus manual aperture lens is used. The focus ring is adjusted to maximize clarity on the CCD target surface, while brightness optimization is achieved by fine-tuning the aperture ring.Camera:

Uses an area-array CCD analog camera with a resolution of 640 × 480 pixels and an image capture speed of up to 60 frames per second, ensuring accurate and efficient image acquisition.

4.4 Bottle mouth detection module:

image processing process

4.5 Test Content and Accuracy:

4.5.1 Test Content

A. Through-hole

B. Internal chip

C. External chip

D. Point chip

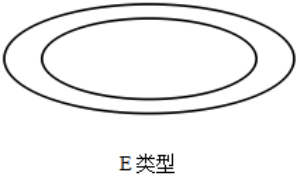

E. Deformed bottle neck (oval)

4.5.2 Detection Accuracy

serial number

| Inspection Contents | Dimensions | Detection accuracy

| False rejection rate

|

1 | Penetration | Vertical section width 0.8mm, depth 0.25mm | ≥99.99% | ≤0.03% |

2 | Internal Defects | Vertical section width 0.8mm, depth 0.25mm | ≥99.95% | |

3 | External Defects | Vertical section width 0.8mm, depth 0.25mm | ≥99.95% | |

4 | Point Defects | Diameter 0.8mm, depth 0.25mm | ≥99.99% | |

5 | Neck Deformation (Oval) | Diameter difference 2mm | ≥99.95% |