Why the Food, Beverage, and Brewing Industries Introduced Machine Vision Inspection Equipment?

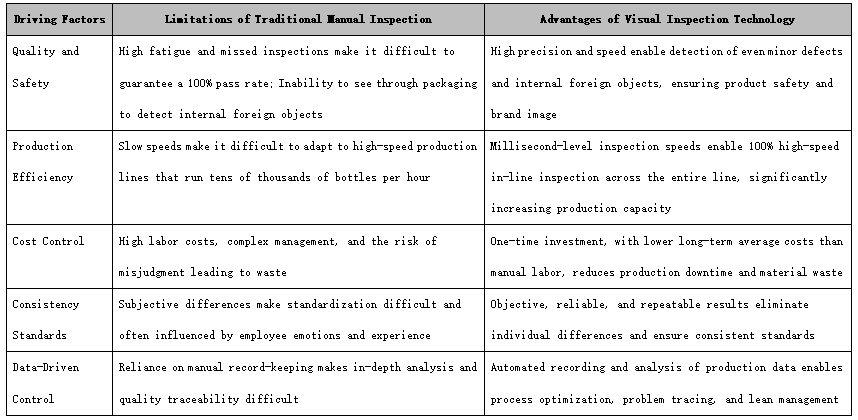

The food, beverage, and brewing industries are introducing vision inspection technology primarily to address multiple challenges, including high-quality control requirements, high-speed production pace, and cost-efficiency optimization. The following table can help you quickly understand the core reasons:

The "eagle eye" of quality and safety

Vision inspection systems are like tireless "super quality inspectors" on the production line. They perform many precise inspections that are beyond the reach of human eyes:

Foreign object and defect detection: The system can detect tiny foreign objects inside bottles and inspect for defects such as cracks, bubbles, and stains on the bottle neck, body, and base, rejecting defective products before filling.

Packaging integrity inspection: This system ensures that labels are printed correctly and positioned accurately, the production date and batch number are legible, the bottle cap is properly sealed, and the packaging is intact. This is crucial for maintaining brand image and consumer safety, especially for accurate labeling of information such as allergens.

Internal quality assessment: It can even analyze visual characteristics of certain foods, such as the crumb structure of bread or the distribution of toppings, to ensure consistent sensory quality.

Compatible with modern high-speed production lines

Modern food and beverage production lines operate at breakneck speeds. For example, some beer lines can produce over 36,000 bottles per hour. Manual inspection simply cannot keep up with this pace. Visual inspection systems can make decisions at millisecond speeds, ensuring 100% inspection of every product on high-speed assembly lines, ensuring high output without sacrificing quality.

Economic Benefits and Long-Term Value

Although visual inspection systems require an initial investment, their long-term returns are significant:

Reduced Overall Costs: A single system can operate reliably and continuously, with average labor costs far lower than employing a large number of quality inspectors. For example, by introducing AI vision technology, Budweiser achieved full automation and reduced overall project costs by 70%.

Reduced Waste and Downtime: The system can detect production process issues (such as raw material color deviation) early, allowing timely adjustments to equipment parameters to reduce subsequent batches of defective products, thereby reducing material waste and production downtime.

Achieving Data-Driven Refined Management

A visual inspection system is not only an inspection tool but also a data collection terminal. It records inspection results and production data for each product. This data can help companies:

Analyze cyclical trends in quality issues and identify root causes.

Optimize production process parameters, such as oven temperature or filling volume control. Establishing a comprehensive quality traceability system allows for quick and accurate tracing back to the production line and specific time point if market feedback indicates a product batch defect.

We hope the above explanation helps you gain a more comprehensive understanding of the importance of visual inspection technology in the food, beverage, and brewing industries. If you'd like more details on a specific application scenario (such as beer bottle inspection or label alignment), we can discuss this in more depth.