PET Label Inspection Machine

1.360 degree inspection

2.Muli view stiching and color recogniton technology are more reliable

3.The maximum speed is up to 36000 BPH

I. Project Design Basis

1. Project Overview

1.1 Project Title: PET Bottle Label Online Inspection System

1.2 Project Scope: This system adopts advanced machine vision technology to carry out fully automated, non-contact online inspection of PET bottle labels. Inspection items include label presence and label height verification.

1.3 Designed Throughput: 60,000 bottles per hour

1.4 Applicable Container: PET bottles

2. Environmental Conditions

2.1 Optimum Altitude: 5-3000 meters above sea level;

2.2 Optimal Operating Temperature: 5°C–40°C

2.3 Optimal Operating Humidity: 50%–65% RH

2.4 Factory Environment Requirements: The workshop must comply with relevant national standards regarding floor flatness, load-bearing capacity, and other parameters to ensure proper machine operation.

2.5 Storage Requirements: Upon delivery to the factory, all parts and equipment must be stored in facilities that meet applicable national standards.

Note: Regular lubrication and maintenance are essential to prevent surface damage or deformation of parts, which could otherwise affect proper installation, commissioning, and long-term operation of the equipment.

3. Equipment Operating Conditions

3.1 Noise: ≤85 dB; actual noise levels may vary depending on the container/package being processed, machine power, and building acoustic characteristics.

3.2 Voltage: 220V, 50Hz, single-phase (special voltages require prior notification).

3.3 Total Power: Approximately 1.0kW; Control Voltage: 24VDC.

3.4 Compressed Air: 0.5MPa, air consumption per rejection cycle approximately 0.01L.

II. Equipment Introduction

1. Installation location: on the single row straight conveyor line behind the labeling machine.

2. System Workflow

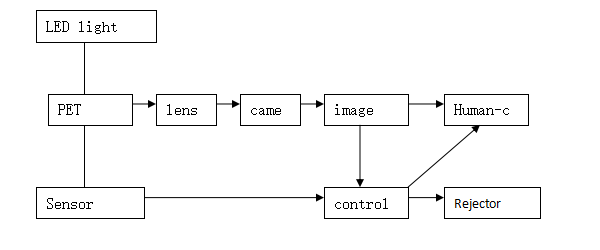

Figure: System working principle and flow chart

3. System Operation

3.1 As each bottle passes the positioning sensor, its presence is detected. The control unit simultaneously records the bottle ID and the corresponding encoder value.

3.2 The positioning sensor then triggers the camera to capture an image of the bottle label. Once the image is acquired, the vision processor analyzes it and sends the inspection results to the HMI for real-time display, while also transmitting the data to the control unit for defect handling.

3.3 If a defect is identified, the control unit issues a rejection command to the rejector, ensuring the corresponding bottle is removed from the line.

4. Image Acquisition Components

4.1 Light Source: The system employs an LED area light source with a service life of up to 50,000 hours. Using front-illumination, it provides clear imaging of the measurement area. On the captured image, the bottle opening is represented as a continuous bright circular ring. A fixed-focus manual aperture lens is applied; the focus ring is adjusted to achieve maximum sharpness on the CCD sensor plane, and the aperture ring is fine-tuned for optimal brightness.

4.2 Camera: The system is equipped with an area-array CCD analog camera offering a resolution of 640 × 480 pixels, with a maximum capture rate of 60 frames per second.

5. Label detection module image

6. Inspection Content and Accuracy

6.1 Inspection Content

1).No label

2).High label

3).Low label

4).Positive and negative label (wrong label orientation)

6.2 Detection Accuracy

serial number

| Test Contents | Testing Accuracy | Rejection rate

| False rejection rate

|

1 | No label | --- | 100% | ≤0.03% |

2 | High label | Deviation ≥ 2mm | ≥99.9% | |

3 | Low label | Deviation ≥ 2mm | ≥99.9% | |

4 | Connection label (tape applied when changing labels, requires a significant color difference between the tape and label) | ≥99.9% |

7. Equipment Structure and Components

7.1 The system is composed of multiple inspection modules and a human-machine interface (HMI), designed for label inspection on high-speed production lines.

7.2 Each inspection module is driven by a reliable industrial-grade control computer, which processes inspection data and communicates with the control system for real-time information transfer.

7.3 The electronic control system integrates imported programmable logic controllers (PLCs), program memory, photoelectric and inductive sensors, together with a comprehensive control program and HMI, forming a highly automated and intelligent control platform.

7.4 A rejection verification module ensures that all defective products are accurately detected and removed from the line.

7.5 The power distribution cabinet is equipped with industrial air conditioning to maintain an optimal operating temperature and extend system service life.

7.6 The compact design of the testing cabinet minimizes the footprint of the equipment.

7.7 Operating conditions and fault diagnostics are visually displayed through the HMI in a clear, graphical format.

8. System Advantages

8.1 The image processing hardware uses state-of-the-art imported components, while the software incorporates dedicated image-processing algorithms, achieving high-speed, high-accuracy, and high-reliability inspections.

8.2 The system allows pre-programming of multiple bottle types and supports quick switching via one-click operation.

8.3 The rejection verification module provides online monitoring, ensuring defective bottles are consistently rejected and enabling a closed-loop quality control process.

8.4 Its modular architecture, with abundant interfaces and reserved space, supports flexible system expansion.

8.5 The equipment features exceptional reliability, a very low failure rate, and straightforward, user-friendly maintenance.