The Eye of Industry: How Machine Vision is Revolutionizing Battery Cap Quality Inspection

Inspecting 400 pieces per minute with an accuracy rate exceeding 99%, this is how the guardian of battery production quality works.

In today's rapidly developing new energy industry, batteries, as the core energy source, require crucial quality control. The battery cap—a seemingly small component—is actually the "gatekeeper" of battery packaging, and its quality directly affects the battery's performance and safety.

Traditional manual inspection methods are no longer sufficient to meet the high-precision, high-efficiency demands of modern production. With the development of machine vision technology, battery cap quality inspection is undergoing a revolutionary transformation.

1. The Shortcomings of Traditional Inspection: Limitations of Manual Inspection

In the past, battery cap inspection mainly relied on manual labor. Quality inspectors had to visually inspect the appearance, dimensions, and solder joints of each cap. This process was not only labor-intensive but also highly susceptible to subjective factors.

Under prolonged work, visual fatigue among quality inspectors led to frequent missed and incorrect inspections. Statistics show that the error rate of manual inspection is as high as 5%-10%, which is unacceptable for the battery industry striving for ultimate quality. At the same time, the speed of manual inspection is limited, only dozens of pieces per minute, severely restricting production efficiency and increasing production costs.

2. The Rise of Machine Vision: Technological Basis and Advantages

Machine vision systems refer to technologies that use machines to replace human eyes to perform various measurements and judgments. It is a comprehensive discipline involving multiple fields such as optics, mechanics, computers, pattern recognition, image processing, artificial intelligence, signal processing, and optoelectronics integration.

A complete machine vision inspection system mainly includes four components: image acquisition module, image processing module, image analysis module, and data management module.

The image acquisition module consists of an industrial camera, optical lens, light source, and its clamping device. Its function is to collect images of the product surface. Under the illumination of the light source, the product surface is imaged onto the camera sensor through the optical lens. The optical signal is first converted into an electrical signal, and then into a digital signal that can be processed by a computer. Compared with manual inspection, machine vision inspection offers significant advantages: it not only improves production flexibility and automation but also enables efficient and precise inspection in working environments unsuitable for human operation or where human vision cannot meet the requirements, greatly improving production efficiency and automation.

3. Technical Implementation: System Architecture for Battery Cap Inspection

A machine vision inspection system for battery caps typically consists of a feeding tray, conveyor belt, inspection station, positioning mechanism, sorting machine, and material bin, forming a complete inspection line.

Taking a typical inspection system as an example, its workflow is as follows: The feeding tray, through continuous vibration, arranges the battery caps according to the required sequence and orientation and transfers them to the conveyor belt; the conveyor belt transports the battery caps at a set speed, passing them through multiple inspection stations in sequence.

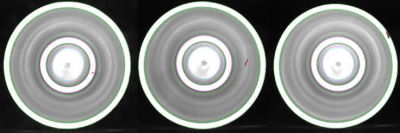

Inspection station 1 is usually equipped with one top camera, three side cameras, and one light source. The top camera is positioned above the battery cap, imaging and taking pictures of the spot-welded surface of the battery cap. The three side cameras are evenly distributed around the battery cap at 120° angles, enabling imaging and picture taking of the sides of the battery cap.

Subsequently, the positioning mechanism rotates the battery cap 180°, so that the arc-welded surface faces upwards. Inspection station 2 is equipped with another imaging system, including one top camera and one light source, to image and take pictures of the arc-welded surface of the battery cap.

In the entire inspection system, the industrial camera is the "eye" of the machine vision system and needs to have high resolution and high frame rate. High resolution ensures that defects as small as 0.01mm on the battery cap, such as tiny scratches and pinholes, can be captured; a high frame rate meets the inspection needs of fast production lines.

The selection of optical lenses is also crucial; lenses with different focal lengths and depths of field need to be selected according to the inspection requirements. A suitable lighting system is also key to obtaining high-quality images.

4. Image Processing and Defect Recognition: Algorithm Working Mechanism

The images captured by the camera undergo a series of complex processing steps, mainly including image preprocessing, feature recognition, recognition results, and classification.

In the image preprocessing stage, the system performs operations such as grayscale conversion, filtering, edge detection, and binarization on the acquired images to improve image quality and reduce noise. Through algorithms such as Gaussian filtering, noise interference is removed from the image, improving image clarity and providing high-quality image data for subsequent analysis.

In the feature extraction stage, the system extracts characteristic information of the battery cap from the image, such as edges, color, and texture, for subsequent classification and identification processing.

Different detection algorithms are required for different types of battery cap defects: For arc welding defects (such as incomplete welding, poor welding, missing welds, offset, and spatter), the Canny edge detection algorithm can be used to extract edges and determine whether the edges meet the requirements.

For spot welding defects (such as missing welds, off-center welds, and weld penetration), the Hough circle detection can be used to determine and extract the smallest circle that can enclose the weld points, and the watershed algorithm can be used to identify the number and position of weld points to determine if they are normal.

For size issues, after extracting the edges through threshold segmentation, the degree of matching between the outer circle edge and the standard circle can be used to determine the conformity of the cap size.

Modern detection systems are increasingly adopting deep learning algorithms. Through deep training on large-scale annotated datasets, they can identify and classify specific defect types through image recognition, enabling continuous optimization of the manufacturing process.

5. Practical Applications and Results: The Value of Machine Vision Inspection

In practical applications, machine vision inspection systems have proven their significant value. A globally renowned battery manufacturer, after introducing a machine vision inspection solution for battery cap inspection, not only reduced the product defect rate from 8% to less than 1%, but also increased production efficiency by six times, saving the company millions of dollars annually.

In terms of detection capabilities, the machine vision system can achieve high-speed automated inspection, with a detection speed of hundreds or even thousands of pieces per minute, far exceeding manual inspection speeds. This significantly increases the capacity of the battery production line, effectively meeting the growing market demand for batteries.

In terms of quality, the machine vision inspection solution can accurately identify various minute defects and size deviations on the battery cap, effectively avoiding omissions in manual inspection. Its high-precision detection capabilities greatly improve the quality stability of battery caps, providing strong support for high-performance and long-life batteries.

The non-contact detection characteristics of the machine vision system also ensure that the detection process does not damage the product, while reducing human error, making the detection results more objective and reliable.

The system can automatically record the images and data of each inspection, facilitating subsequent inquiries and traceability. Through statistical analysis of a large amount of inspection data, companies can gain a deep understanding of quality fluctuations in the production process, promptly identify potential problems in the manufacturing process, and provide strong support for process optimization.

6. Future Outlook: The Development Path of Intelligent Upgrades

With the rapid evolution of artificial intelligence technology, machine vision inspection of battery caps is developing towards a more intelligent direction. The integration of 3D sensing hardware and artificial intelligence software has brought new breakthroughs to inspection systems.

For example, 3D sensors can capture thousands of data points and convert these data points into very detailed point clouds and depth maps, allowing AI software to detect defects. This technology has already helped automotive OEMs reduce the defect rate of complex components by 10%-15%.

The fusion of 2D and 3D data will become an important trend in the future. Machine vision experts are using a new generation of intelligent cameras and sensors to build automated vision solutions: high-speed acquisition of higher-quality 2D/3D data for deep learning model training and testing.

As automotive OEMs begin to transition to electric vehicle manufacturing, machine vision, 3D scanning, and AI technologies will play a greater role in more frontline operational processes. For example, detecting defects in battery cells, and evaluating the size and integrity of tabs and connectors—these inspections are challenging due to the common reflective problems of metal surfaces.

Using 3D sensors can effectively solve the problem of insufficient contrast by accurately scanning the surface to detect defects.

Future inspection systems will focus more on self-learning and self-adjustment capabilities, continuously improving detection accuracy and efficiency through continuous data accumulation and algorithm optimization, achieving the goal of continuous improvement of "getting better every day."

With the in-depth development of intelligent manufacturing in digital factories, more and more companies are adopting machine vision inspection systems. After a globally renowned battery manufacturer introduced a machine vision inspection solution, the product defect rate decreased from 8% to less than 1%, production efficiency increased sixfold, and millions of yuan in costs were saved annually.

Machine vision technology is reshaping the landscape of battery cap inspection, bringing higher quality, higher efficiency, and lower costs to battery manufacturers. With continuous technological advancements, it will undoubtedly play an even more important role in the battery field, providing a solid guarantee for the sustained growth of the new energy industry.