Tetra Pak Straw Position Detection

1.Independent research and development of inspection software, the fastest processing speed is up to 60000 BPH

2.Insteadoflabor,saved cost ofproduction and high performance p rice ratio

3.Unique lightingdesign,no impact of natural light

I. Equipment Introduction

1. Purpose

This system is designed to perform online inspection of inkjet printing and straw quality on packaging products. It uses a Gigabit Ethernet digital camera to capture top-down images, which are analyzed in real time to identify and eliminate defective packages.

As each package passes a positioning sensor, the sensor detects its presence and sends a signal to the control unit. At the same time, the control unit logs the package’s ID and encoder data. The camera is then triggered to capture an image of the package’s inkjet code and straw, which is transmitted to the image processor via the network.

The image processor analyzes the captured image and sends the results simultaneously to:

the HMI (Human-Machine Interface) for real-time monitoring, and

the control unit, which issues commands to the rejector.

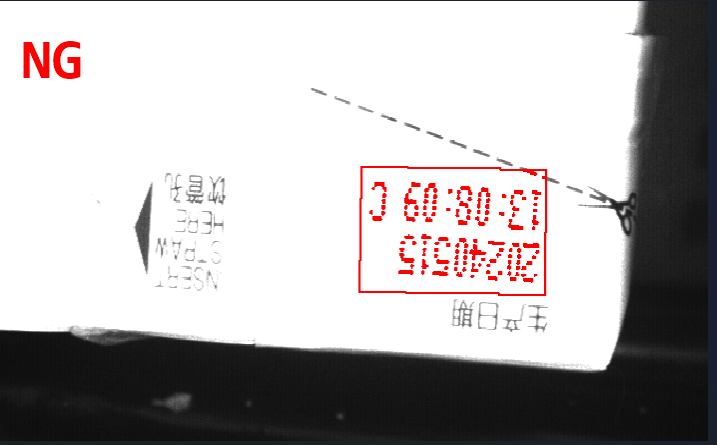

If a defect is detected, the rejector immediately removes the specific package (identified by its inkjet code) or any non-compliant items from the production line.

Algorithm Principle

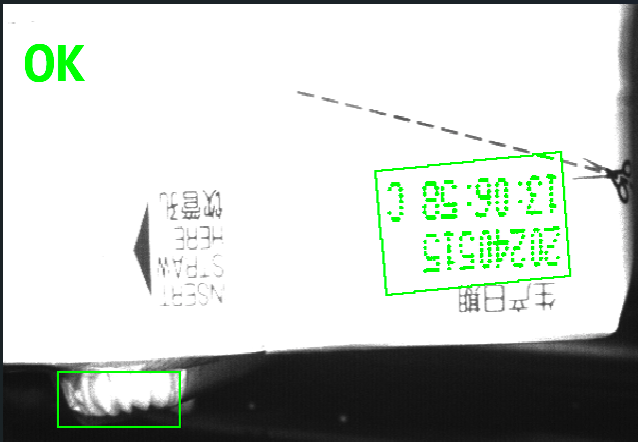

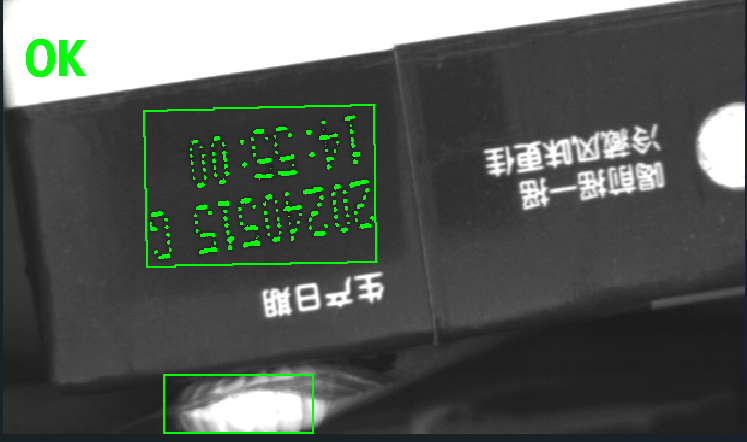

The system incorporates deep learning technology, minimizing manual intervention. For new product models, only about 300 sample images are required to train the system. Our company builds and maintains the data model, ensuring comprehensive coverage of product types and achieving truly foolproof defect detection. (Sample software interface screenshots are provided below.)

II. Detection Functions

Code presence check (missing code, inverted package)

Blurred or illegible code (distorted characters, unreadable text)

Code errors

Missing characters

Character recognition (decoding code content)

Position deviation (beyond preset range)

Duplicate code detection

Straw presence verification (missing straw)

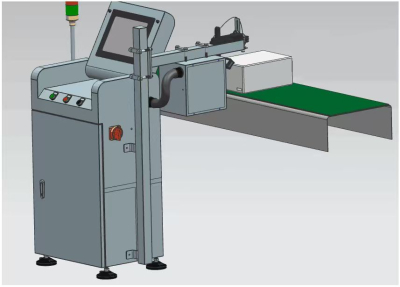

III. Installation Location

The system should be installed on the conveyor line 0.5–1.0 meters downstream of the tube applicator, allowing inspection of both the inkjet code and the straw.

IV. Detection Principle

The Gigabit Ethernet digital camera captures images of each package from top to bottom. These images are processed digitally to detect defects, and defective items are automatically rejected.

The workflow is as follows:

The positioning sensor detects the package and logs its ID with the encoder signal.

The sensor triggers the camera to capture an image.

The image is transmitted to the processor for analysis.

Results are displayed dynamically on the HMI and sent to the control unit.

The rejector removes any defective package in real time.

By applying deep learning algorithms, the system adapts efficiently to different product types, requiring minimal manual adjustment and ensuring reliable, error-proof inspection.

V. Equipment Configuration and Inspection Accuracy

(I) Detailed Equipment Description

A. Technical Specifications

• Equipment Name: Inkjet Printer Inspection Machine

• Model: MT-LL-PM-C1-01X

• Maximum Production Speed: 24,000 bags/hour

• Inspection Scope: Inkjet printing and straw quality

• Rejection Method: Precise removal of defective bags identified by the inspection unit

• Protection Rating: IP65

B. Primary Applications

The system is widely applied in paper-packaged beverage production lines, where it inspects inkjet printing quality and automatically rejects faulty packages.

C. Key Features

1. Minimizes labor demand and lowers overall production costs.

2. Enhances production efficiency while ensuring higher product quality.

3. Delivers inspection results that fully comply with the manufacturer’s technical standards.

D. Detection accuracy:

Serial Number

| Inspection Items | Testing Conditions and Accuracy | Rejection rate

| False kick rate

|

1 | Inkjet Printing Inspection | -- | -- | < = 0.03% |

1.1 | No inkjet printing (missing code, reversed package) | -- | >99.99% | |

1.2 | Missing inkjet printing Blurred inkjet printing | Overall code missing >50% | ≥99.99% | |

Overall code missing >30% | ≥99.96% | |||

1.3 | Incorrect inkjet printing | Code characters unreadable to the human eye | >99.93% | |

1.4 | Position offset | Incorrect production date, incorrect factory code, incorrect security code, deformation (elongation or shortening) | >99.99% | |

1.5 | Duplicate code | Exceeding the expansion zone | >99.99% | |

1.6 | Straw inspection | Multiple codes printed within the code area | >99.99% | |

2 | Inspection Items | No straw | >99.99% | <= 0.01% |

Note: The rejection rate for the "No Coding" test item in the table indicates that for every 10,000 uncoded packages tested by the equipment, one package might not be rejected. This is theoretical experimental data only, and the same applies to other test items. The above test items are tested in real time for each paper package, not just during shift changes to determine coding errors.