Carton Box Weight Machine

1.The special gravity sensor satisfies the quasi dynamic measurement and is easy to adjust

2.Built-inclientvarious boxes of procedures,just clickon the software can quickly change boxes.

3.Equipment maintenance is verylow

4.The systemis modulardesign, rich interface and space, which makesthe equpmentgetgreatdevelopment ability

Maotong Series Weighing and Sorting Scale

The Maotong series checkweigher is a high-speed, high-precision online inspection system designed for automatic weight verification, tolerance checking, and weight-based classification or sorting in a wide range of automated production and logistics lines. It can be seamlessly integrated with various packaging lines and conveyor systems, making it widely applicable in industries such as pharmaceuticals, food and beverage, toys, hardware, and chemicals. By replacing manual weighing, it significantly enhances efficiency, consistency, and reliability in production.

Key Features

Built with high-precision sensors powered by advanced, high-speed digital signal processing technology.

Incorporates automatic zero-point analysis and proprietary tracking algorithms.

Supports storage of up to 200 product records.

Quick-release conveyor design for easy cleaning and maintenance.

Features a rod-type rejection mechanism for reliable removal of defective items.

Dual-language interface with Chinese/English menus (English optional).

Adjustable conveyor speed to adapt to on-site requirements while maintaining high accuracy.

Proprietary dynamic weighing anti-interference correction technology with automatic zeroing ensures superior weighing precision and speed compared to similar devices.

Enhances factory-level weight control, preventing out-of-spec products and reducing customer complaints.

Parameter introduction

Model | MT-CZ-CK200-02 |

Weighing Section Dimensions (mm) | 670 |

Belt Width (mm) | 530 |

Weighing Length (mm) | 650 |

Reject Length (mm) | 0 |

Belt Clearance (mm) | Customized on-site |

Conveyor Roller | NSK bearings, equipment included |

Display Scale | 0.01g |

Display | 10-inch industrial color touchscreen |

Sensor Brand and Range | Mettler Toledo high-precision sensor, 50kg, industry nameplate |

Main System | Independently developed microcontroller |

Inverter | Danfoss |

Alarm Method | Acousto-visual alarm/push-rod roller rejection |

Material | Entire frame constructed of food-grade 304 stainless steel |

Belt | Food-grade belt |

Motor | JSCC precision grinding |

Belt Speed | Adjustable speed |

Sensitivity | ±50g |

Detection Speed | 60 cartons/minute |

Cylinder and Solenoid Valve | No rejection |

Remarks | Package dimensions (mm): 300*180*370 (length, width, height), depending on product dimensions and installation environment (wind, vibration, temperature, humidity, etc.) |

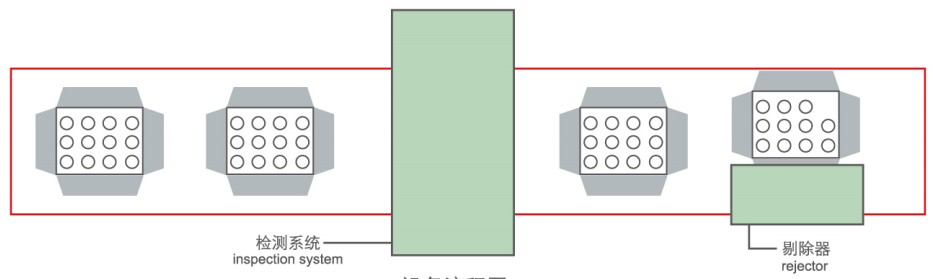

Equipment Overview (see diagram):

The checkweigher consists of two sections: a matching section and a weighing section. Materials are fed at a constant speed through the matching section and then into the weighing section. The system determines whether the weighing data is acceptable or unacceptable. Acceptable materials are discharged, while unacceptable materials are alarmed and shut down.