Fill Level Inspection

1.Automatically adapt to the speed of different production lines, dynamic inspection

2.No radioisotope source, and uses soft ray design.Ray protection is safe and reliable

3.Using hardware circuit design, self-developed inspection software, high degree of optimization,fast processing speed, the maximum speed of up to 72000 BPH

I. Project Overview

1. Project Name: Liquid Level Detector

2. Project Description: Detects product liquid levels and accurately rejects them online

3. Maximum Output: 72,000 bottles (cans)/hour (High-End Model)

4. Container Materials: Aluminum, tinplate, PE/PET/PP, ceramic, glass, etc.

5. Product Specifications: 200-2000ml, diameter 30-90mm, can height 50-200mm

6. Model: MT-HFX-06

II. Environmental Conditions

Altitude: Suitable for installation and operation at 5–3000 m above sea level.

Ambient Temperature: Recommended operating range 5°C–40°C.

Relative Humidity: Optimal range 50%–65% RH.

Factory Requirements: Floor flatness, load-bearing capacity, and other site conditions must conform to relevant national standards to ensure stable and reliable operation.

Storage Requirements: After delivery, equipment and components must be stored under conditions compliant with applicable standards. During storage, proper lubrication and maintenance must be performed to prevent corrosion, deformation, or damage that could affect installation, commissioning, or performance.

III. Production Requirements

Power Supply: 220V, 50Hz, single-phase (provided by the customer). For non-standard voltages, advance notice is required, as this may influence technical specifications, delivery timelines, and pricing.

Total Power Consumption: Approx. 1.0 kW.

Control Voltage: 24 VDC.

Compressed Air Supply: 4–12 Pa (customer provides the pipeline connection from air source to main equipment).

IV. Equipment Overview

1. Installation Plan

Positioning: To be installed downstream of the filling machine, either before or after the inkjet printer.

Requirements: The conveyor line must include a straight, single-lane section of at least 2 m in length.

Timeline: Installation can be completed within 24 hours.

Track Modification: A guardrail opening (≤15 cm) should be made on the conveyor section to allow rejected bottles to exit.

System Composition: The system consists of the inspection module, rejection device, power distribution cabinet, HMI, electronic units, and mechanical assemblies.

Defective Bottle Collection: It is recommended that a rigid collection container be installed at the rejection point.

2. Inspection Scope

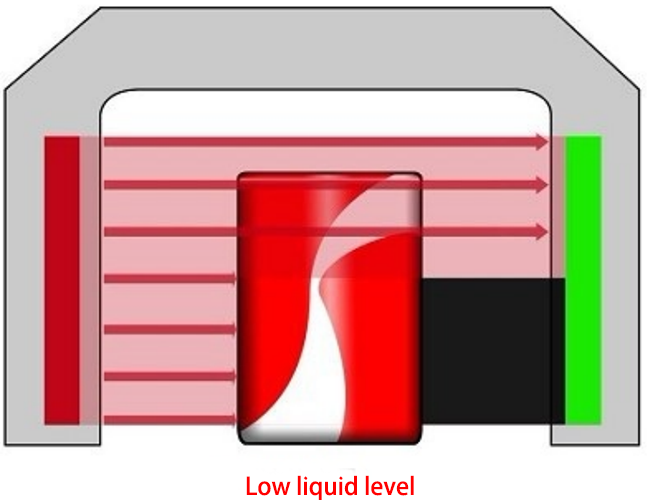

Low liquid level detection (primary function)

High liquid level detection (auxiliary function)

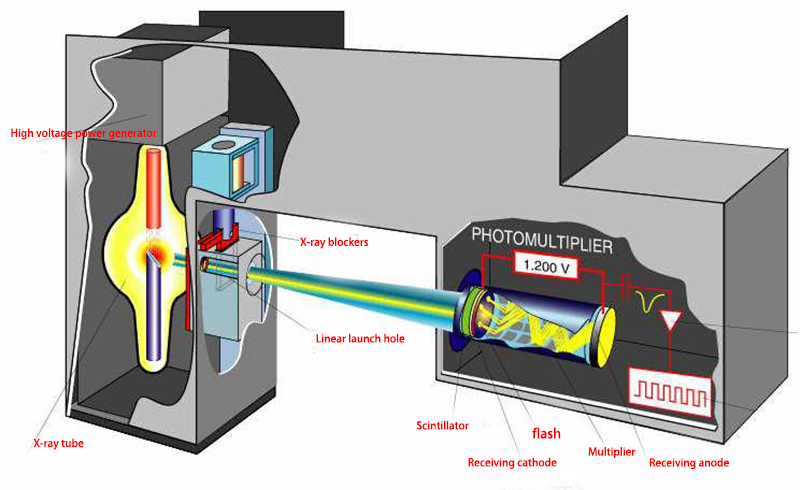

3. Detection Principle

The system operates on the principle of X-ray penetration. Containers with different liquid levels produce distinct projection patterns at the receiving sensor, resulting in varying signal values. These signals are compared against predefined thresholds. If a container falls outside the acceptable range, it is automatically flagged as defective and rejected.

4. Equipment Features

Non-contact, in-line inspection without damaging containers.

Encoder-based bottle counting ensures rejection accuracy, unaffected by line stops or speed changes.

Automatically adjusts to variations in production speed for real-time dynamic detection.

Independent inspection and control cabinets minimize electromagnetic interference, ensuring reliable performance.

Stainless steel housing with sealed structure provides resistance to moisture, condensation, and water droplets, making the system suitable for harsh production environments.

Automatic X-ray deactivation when idle.

Embedded operating system combined with hardware circuitry ensures long-term stability.

Integrated visual and audible alarms with automatic rejection of defective containers.

5. Technical Specifications

Conveyor Speed: ≤1.6 m/s

Applicable Container Diameter: 20–120 mm (depending on material density and container size)

Dynamic Detection Accuracy: ±1.5 mm (subject to foam or turbulence effects)

Static Detection Accuracy: ±1 mm

Rejection Accuracy: ≥99.99% at inspection speeds up to 400 bottles/min

Operating Conditions:

Temperature: 0°C–40°C

Relative Humidity: ≤95% (at 40°C)

Power Supply: 220V ±20V, 50Hz