Liquid Level Capping Detection Machine

1.Using graphical man-machine interface , intuitive and concrete

2.The processing speed is fast, the inspection accuracy is high, the fastest speed can reach 50000 BPH

3.Simple operation, easy to production line staff

4.Multi angle inspection, no dead angle, less manual intervention, low false tick rate

5.Using high brightness LED light source, adjustable brightness, long lfe, energy saving,maintenance free

I. Project Equipment Overview

1. Project Name: PET Bottle Capping, Anti-theft Ring, Liquid Level, and Inkjet Printing Inspection Project

2. Project Description: Inspect and automatically reject caps, anti-theft rings, liquid levels, and inkjet printing on PET bottles

3. Maximum Output: 60,000 bottles/hour

4. Bottle Type: PET Bottle

5. Product Capacity: 200ml-2L

II. Environmental Conditions:

1. Optimum Altitude: 5-3000 meters above sea level;

2. Optimum Ambient Temperature: 5°C-40°C;

3. Optimum Ambient Humidity: 50-65% RH;

4. Factory Conditions: Parameters such as floor levelness and load-bearing capacity must meet relevant national standards and meet the normal operating requirements of the machine;

5. Factory Storage Conditions: After arriving at the factory, parts and machines must be stored in a location that meets relevant national standards. During storage, proper lubrication and maintenance must be performed to prevent damage to the surface of the parts or deformation that could affect normal installation, commissioning, and operation of the machine.

III. Equipment Production Status:

1. Power Supply: 220V, 50Hz, single-phase; provided by the customer (special voltages require prior notification; equipment specifications, delivery time, and price may vary).

2. Total Power: Approximately 2.4kW;

3. Control Voltage: 24VDC.

4. Compressed Air: Minimum 4 Pa, Maximum 12 Pa (customer provides the air line connection from the air source to the equipment main unit).

IV. Equipment Introduction

1. Installation Location

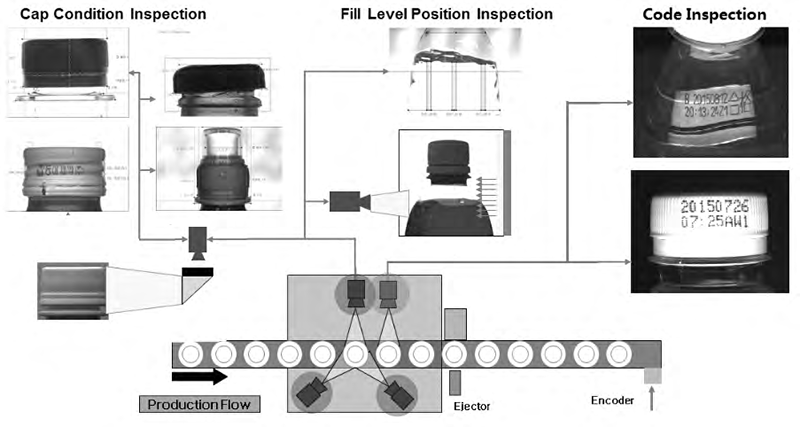

2. Inspection Contents

◆ No cap

◆ High cap

◆ Crooked cap

◆ Broken ring

◆ Low liquid level

◆ Presence of inkjet printing

◆ Excessive inkjet printing

3. Detection principle

1). A PET bottle passes through a positioning sensor. Upon detection, the control unit records the bottle ID and the current encoder signal.

2). The positioning sensor signals a camera to capture an image of the bottle cap, liquid level, and inkjet printer. After capturing the image, the image processor processes the image and transmits the result to the human-machine interface for dynamic display and to the control unit PLC to prepare for the rejection of unacceptable bottles.

3). Upon receiving the unacceptable signal, the control unit notifies the rejector to reject the bottle with the corresponding ID.

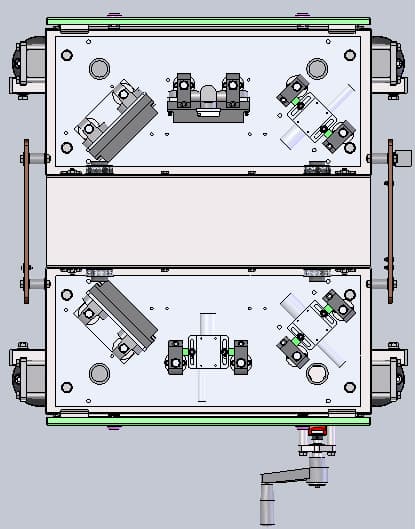

4. Equipment mechanical components

model

| Name | Components | Functional Description | Remark

|

1 | Distribution cabinet | Composed of an image processor, an interface processor, a strobe controller, and a PLC. | Provides power to the entire system, processes images, and controls the rejection of defective products. | |

2 | Detection module | LED light source, industrial CCD camera, and sensor. | Dynamically captures images of PET bottles. | |

3 | Rejection device | Main components include solenoid valves and mechanical components. | Receives signals and controls the rejection of defective products. |

5. Electrical composition of the equipment

model

| Name | Unit | Brand Notes | Quantity |

1 | Embedded imaging industrial computer (4 Ethernet ports) i5+4G+120G | Unit | Taiwan Chaoen, dust-proof, fast processing speed, and excellent stability | 1 |

2 | DAHUA high-speed gigabit digital camera | Unit | Resolution 680x480, imported from Canada, industry-leading brand | 4 |

3 | Camera I/O module | Set | Made-in-China | 4 |

4 | Lens | Piece | COMPUTAR 6MP, 12mm | 4 |

5 | Camera-50/30line cable | Piece | Made-in-China, 5m | 4 |

6 | MW.24v DC power supply 75/120W (DRP-75/120-24) | Piece | Taiwan Mean Well | 2 |

7 | PLC | Piece | Maotong independently developed | 1 |

8 | Touchscreen display | Piece | Taiwan IEI 15-inch | 1 |

9 | Light source controller | Unit | Customized in China, 4-way asynchronous triggering, screen flicker control technology, significantly extending light source life | 1 |

10 | Photo light source | Unit | Customized surface lighting, infrared, and blue | 4 |

11 | Power distribution cabinet | Piece | Made-in-China, 304 material, brushed, pickled, oxidized, and brushed finishes | 1 |

12 | Single-stage rejector Mono | Piece | Customized, air-push type, 304 material | 1 |

13 | Reject unit cylinder | Piece | Norgren high-speed cylinder, UK | 1 |

14 | Reject unit solenoid valve | Piece | MAC high-speed solenoid valve, US, 4.9ms response speed | 1 |

15 | Encoder | Piece | Made-in-China, Hode, incremental type | 1 |

16 | Low-voltage electrical components | Piece | Schneider, France | Several |

17 | Image processing system | Piece | Maotong independently developed, can develop V3.0 according to customer needs | 1 |

18 | Special equipment refrigeration unit - industrial air conditioner | Piece | Shanghai Highly Special, cooling capacity 320W | 1 |

19 | Terminal blocks | Piece | Honeywell, USA | Several |

20 | Photoelectric sensor | Piece | Leuze, Aurora PNP | 1 |

21 | Other electrical components | Piece | - | Several |

22 | Cabinet material and surface treatment | Piece | 304 material, igus® mechanical parts, brushed, pickled, oxidized, and brushed finishes. | 1 |

23 | Alarm light | - | Several | |

24 | Oil-water separator | - | Schneider tri-color tower light | Several |

25 | Relay | Piece | 1 | |

26 | Glass material | Piece | AirTac | 1 |

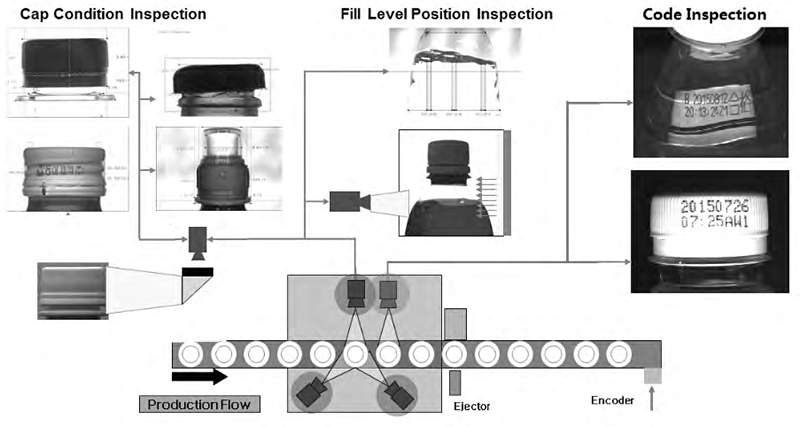

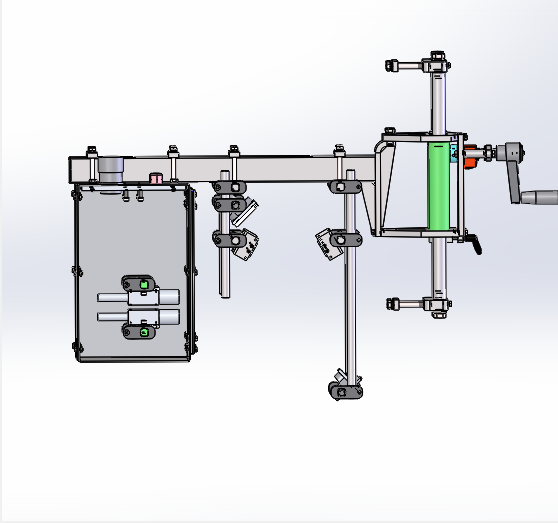

6. Testing cabinet structure diagram

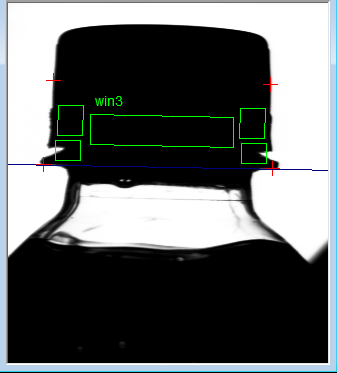

Capping liquid level detection (capping liquid level detection at stations one and three)

Inkjet printing inspection (station 2, single-camera inkjet printing inspection)

This module uses three CCD cameras to capture images of bottles from different angles, reducing blind spots. Special optical lenses filter light from all directions to ensure efficient image acquisition. Its primary function is to detect defective bottles such as missing caps, overhanging caps, crooked caps, and broken caps.

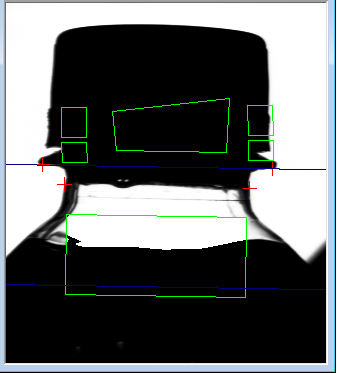

8. Liquid Level Detection

This module uses a CCD camera to capture liquid level images from the front, ensuring that the liquid level in the bottle is nearly horizontal when the bottle is stationary. This module employs image processing principles that render the portion below the liquid level black in the image and the portion above the empty bottle white. A special method is used to distinguish between levels below and above the specified liquid level.

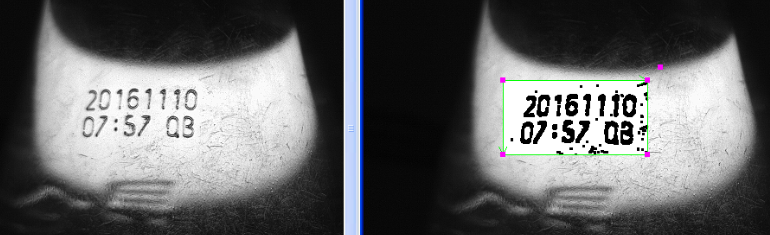

9. Inkjet Printing Inspection

This module uses a CCD camera to capture images of the inkjet printing on bottles and caps from the front. It then digitally analyzes the captured images and automatically and accurately rejects bottles with unqualified inkjet printing. It is compatible with both yellow caps with black ink and black caps with white ink.

10. Detection accuracy

Inspection Items | Inspection Contents | Detection accuracy

| Rejection rate

|

| No cap | —— | ≥99.99% |

High cap | >0.8 mm | ≥99.98% | |

Crooked cap | >0.8 mm | ≥99.5% | |

Safety ring 100% disconnected | >1mm gap | ≥99.99% | |

Safety ring >70% broken | >1mm gap | ≥98.32% | |

Safety ring >50% broken | >1mm gap | ≥95.78% | |

Safety ring 100% missing | —— | ≥99.99% | |

Safety ring 70% missing | —— | ≥98.21% | |

Safety ring 50% missing | —— | ≥95.78% | |

Inspection Items | Liquid level detection (high and low) | 3mm below (or above) the standard

| ≥99.92% |

Bottle Cap Inspection | No inkjet print | ≥99.99% | |

Overall inkjet print 50% missing | ≥99.95% | ||

Overall inkjet print 30% missing | ≥99.9% | ||

Overall inkjet print 20% missing | ≥99.8% | ||

Inkjet print is blurred enough to remove the inkjet characters after processing | ≥99.99% |